Manufacturing method of environmentally-friendly type hot galvanized steel pipe

A manufacturing method, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as easy darkening of steel pipes, hexavalent chromium hazards, black spots, etc., and achieve excellent corrosion resistance The effect of performance, large industrial value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

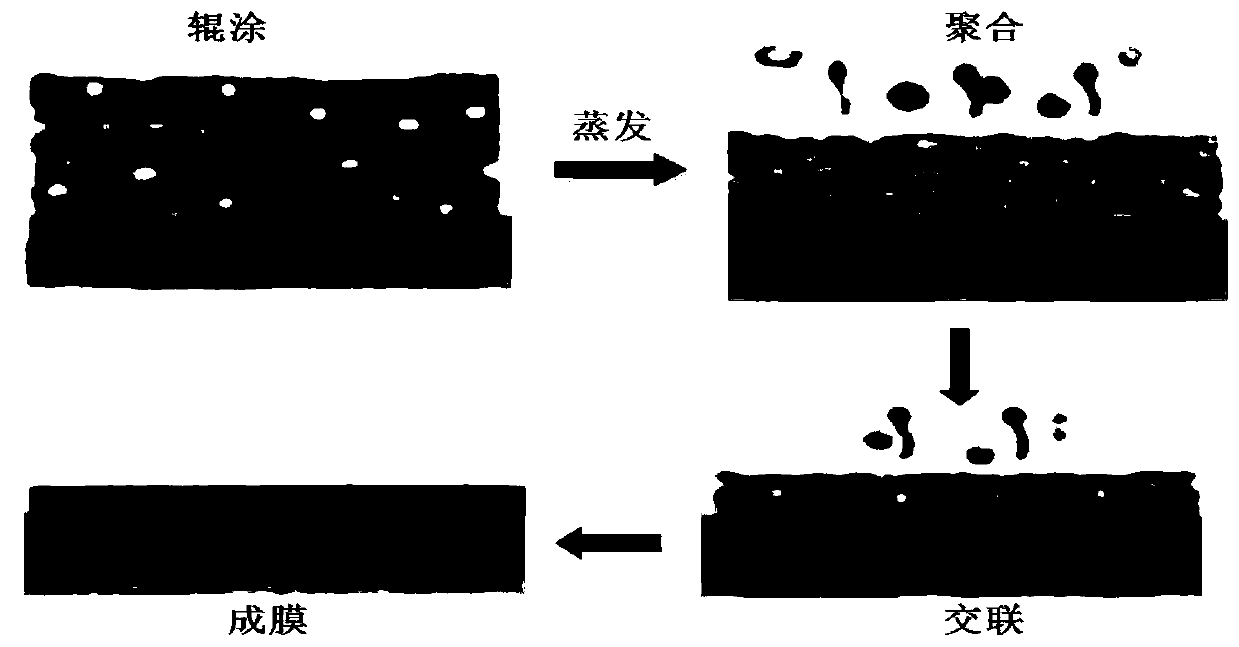

[0048] An environment-friendly manufacturing method of hot-dip galvanized steel pipes. First, the steel pipes are subjected to pretreatment and hot-dip galvanizing, and then a chromium-free passivator is sprayed on the outer surface of the galvanized steel pipes by spraying, and then the surface of the steel pipes is blown off with an air knife. The excess passivating agent effusion, then dry the passivated steel pipe at 80°C for 6 minutes.

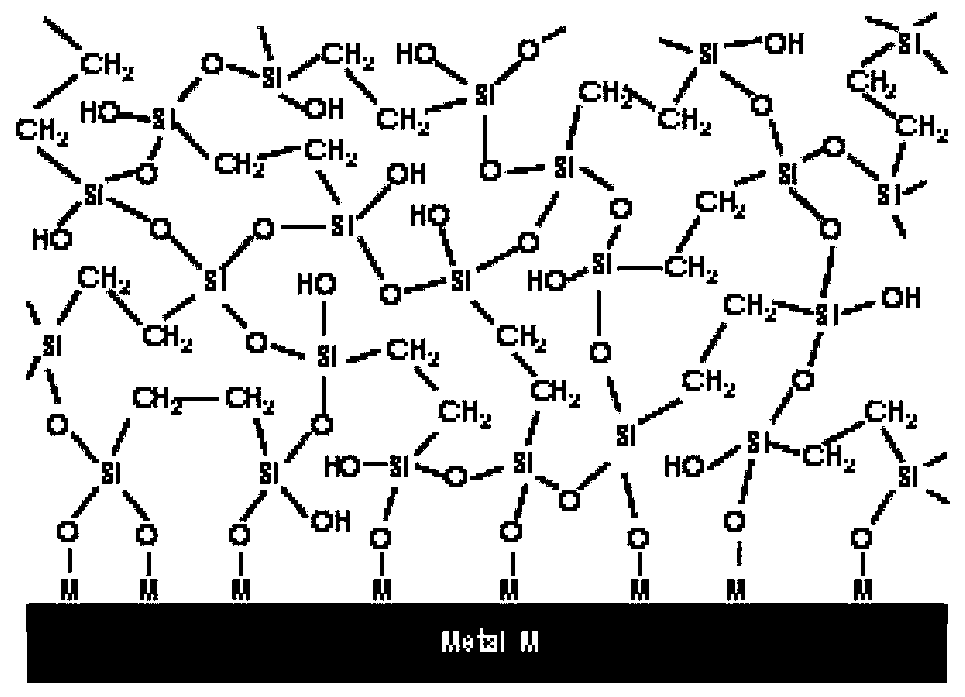

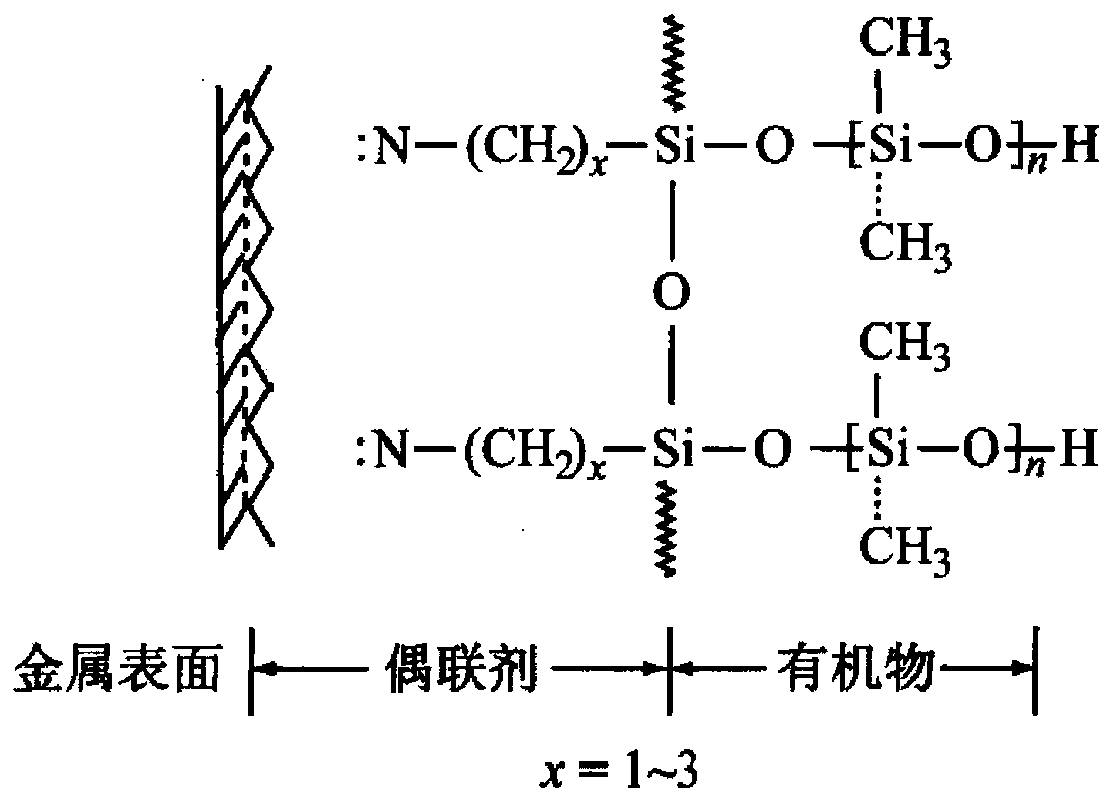

[0049]Wherein, the water-based chromium-free passivator includes the following components: (A) anionic acrylic modified epoxy resin, (B) nano-scale modified alkaline silica sol, (C) sodium molybdate, (D) zirconium carbonate Ammonium; Calculated with the mass ratio after folding, the mass ratio of (A) to (B) is 1.2, the mass ratio of Mo and [(A)+(B)] in sodium molybdate (C) is 0.005, ammonium zirconium carbonate (D) ZrO 2 The mass ratio to [(A)+(B)] is 0.1.

[0050] The chromium-free passivator is prepared according to the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com