Dyeing solution for nylon parts and surface color treatment method for nylon parts

A dyeing solution and color treatment technology, applied in the field of dyeing agents, can solve the problems of poor roughness, harsh treatment conditions, and difficult to overcome laminated textures, etc., and achieve the effects of small shrinkage, good light resistance, and easy fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

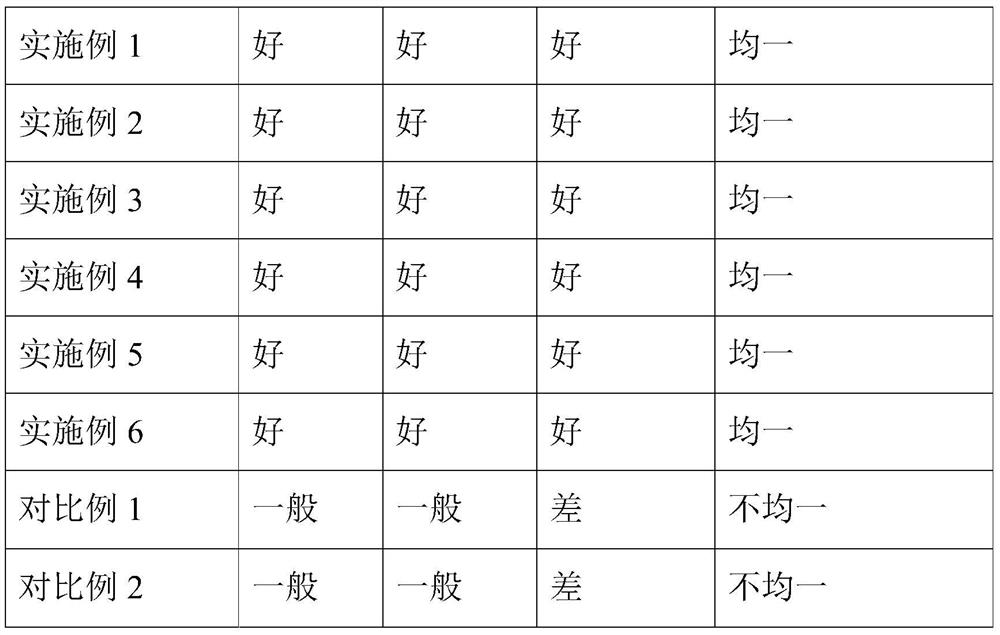

Embodiment 1

[0027] Pretreatment of 3D printed nylon parts: Add abrasives, water and polishing liquid into the polishing equipment, mix them evenly and put in an appropriate amount of 3D printed parts, set the polishing drum speed between 10-2000r / min, set the polishing time at Between 1min-30min, turn on the polishing equipment to complete the polishing of the 3D printed parts. After polishing, turn off the polishing equipment, drain the water and polishing liquid, take out the 3D printed nylon parts and clean them.

[0028] In parts by weight, take 12 parts of n-butanol and 12 parts of butyl acetate, mix and stir at room temperature for 30 minutes, add 26 parts of succinic acid epoxy acrylate, mix and stir evenly, then add 10 parts of formic acid, 15 parts of acid dye , 0.5 parts of leveling agent, add an appropriate amount of glacial acetic acid to adjust the pH to 4-6, and add 0.1 parts of sodium acetate as a buffer solution, stir evenly; put in pretreated 3D printed nylon parts, and he...

Embodiment 2

[0030] In parts by weight, take 6.25 parts of n-butanol and 6.25 parts of butyl acetate, mix and stir for 30 minutes at room temperature, add 37.5 parts of adipic acid epoxy acrylate, mix and stir evenly, then add 10 parts of formic acid, 15 parts of acid dye , 0.5 parts of leveling agent, add an appropriate amount of glacial acetic acid to adjust the pH to 4-6, and add 0.1 parts of sodium acetate as a buffer solution, stir evenly; put in the pretreated 3D printed parts, and heat up at a rate of 1 °C per minute Keep heating at 96°C for 30 minutes, take out the dyed 3D printed nylon parts, wash them with distilled water three times, and dry them in an oven at 80°C for 12 hours to obtain nylon parts with smooth surface and uniform color.

Embodiment 3

[0032] In parts by weight, take 6.25 parts of n-butanol and 6.25 parts of butyl acetate, mix and stir at room temperature for 120 minutes, add 37.5 parts of polyethylene glycol (400) diacrylate, mix and stir evenly, then add 25 parts of formic acid, 30 1 part of acid dye, 1 part of leveling agent, add an appropriate amount of glacial acetic acid to adjust the pH to 4-6, and add 0.5 part of sodium acetate as a buffer solution, stir evenly; put in the pretreated 3D printed parts, and raise the temperature by 3 °C per minute The speed was raised to 120°C, and the heating was maintained for 120 minutes. The dyed 3D nylon printed parts were taken out, washed 3 times with distilled water, and dried in an oven at 80°C for 12 hours to obtain nylon parts with smooth surface and uniform color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com