Method for passivating single-crystal surface by tungsten oxide

A tungsten oxide, single crystal silicon technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as inability to apply solar cell technology, instability, etc., to achieve high film purity and density, The effect of unique film structure and performance and simple film formation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

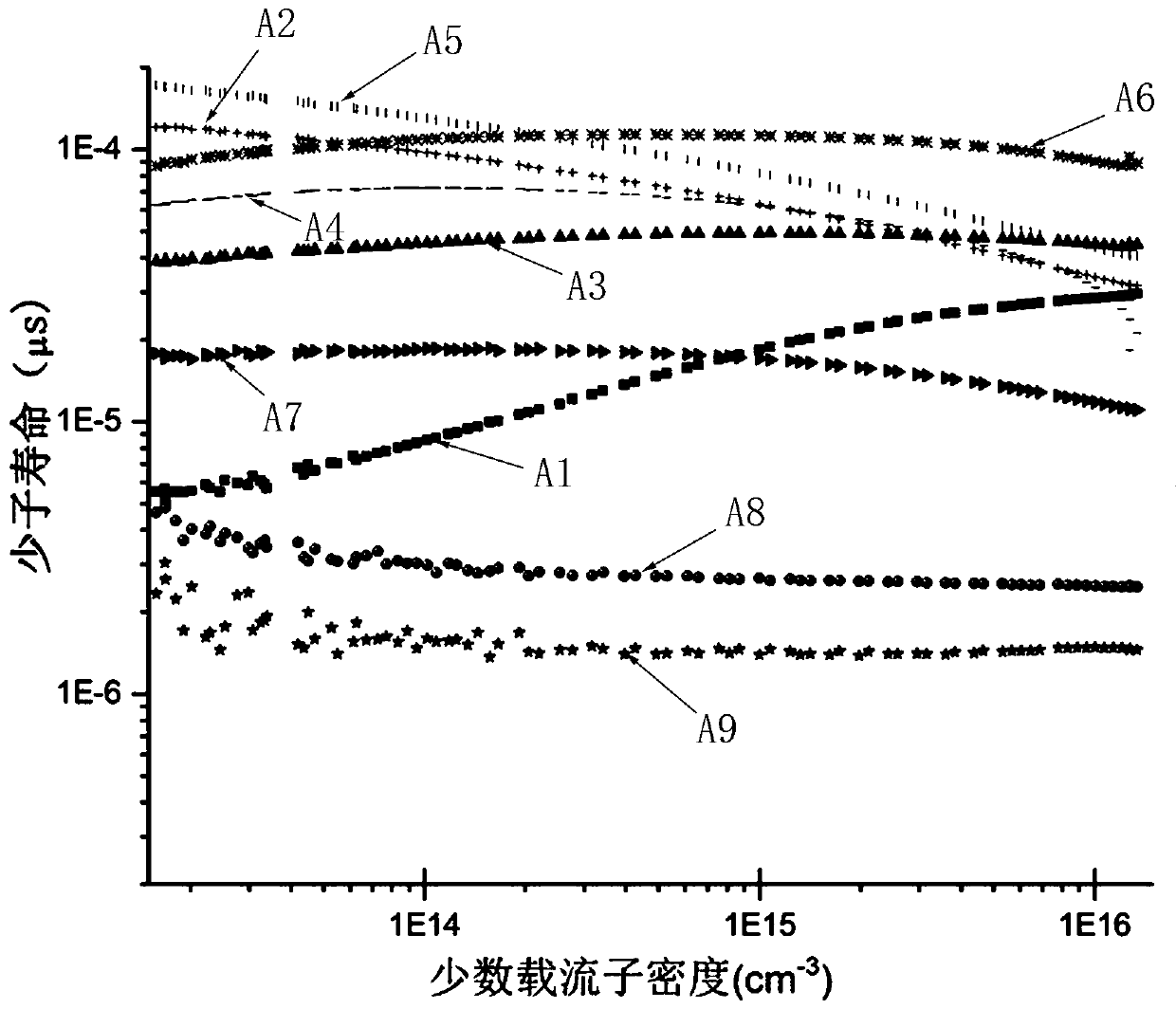

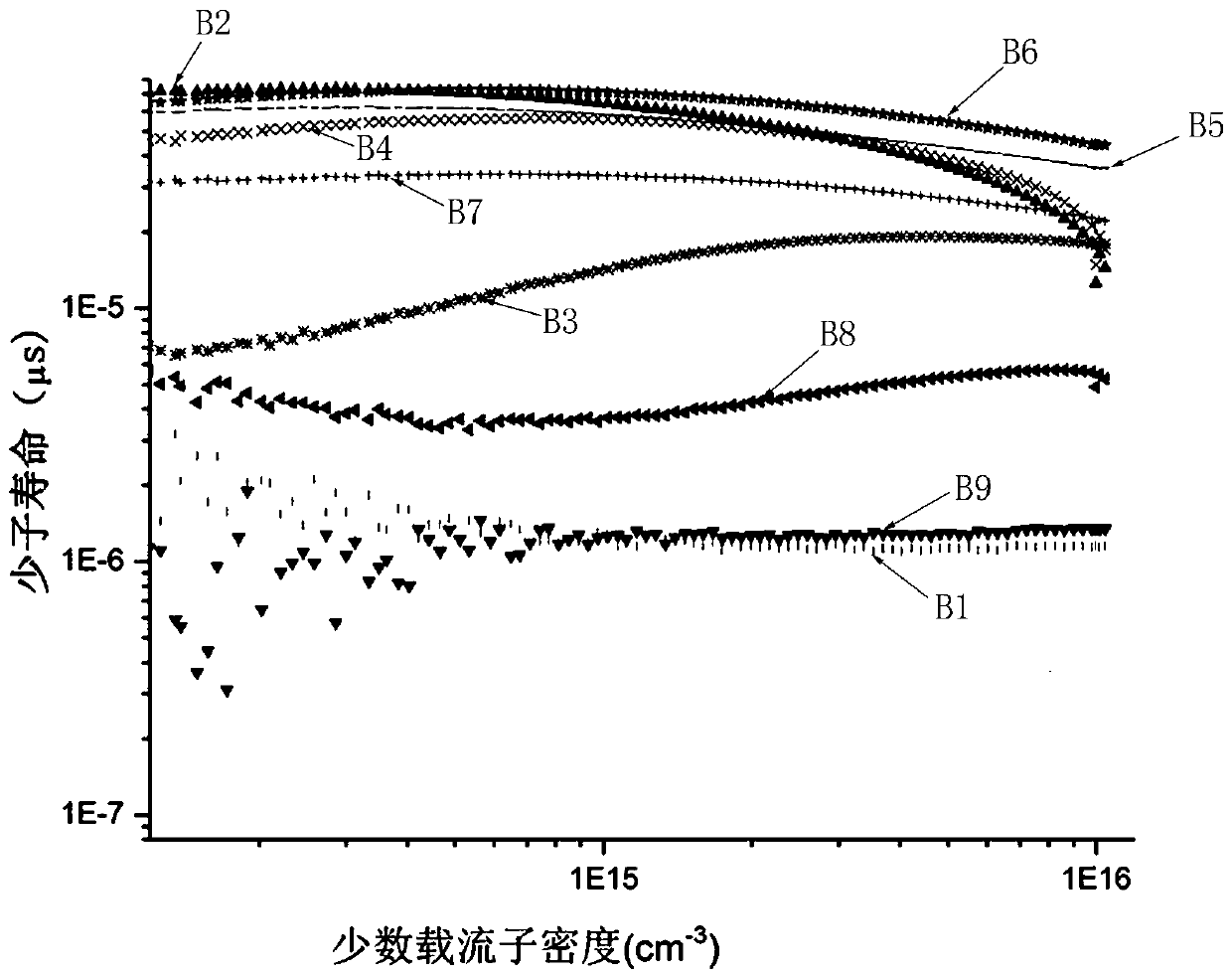

Image

Examples

Embodiment Construction

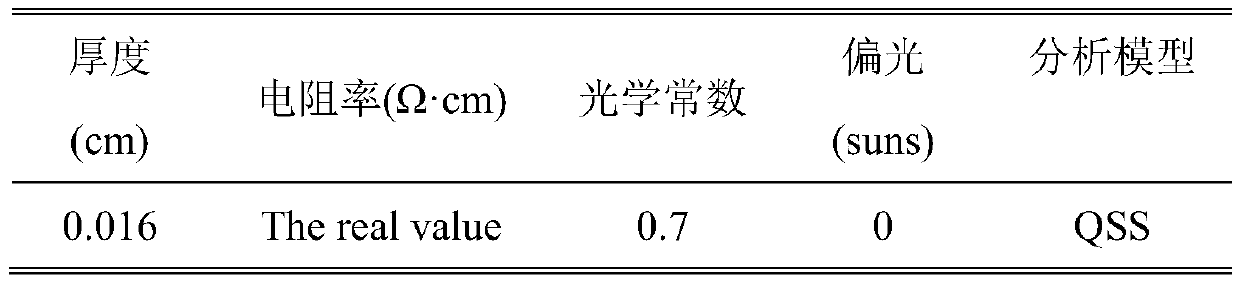

[0013] The samples used in the present invention are N type single crystal non-polished silicon chips with an area of 40 mm*40 mm and a thickness of 190 μm, and the resistivity is 1-5 Ω·cm. The specific connotation of the present invention will be further elaborated below in conjunction with specific embodiments.

[0014] (1) No silicon dioxide layer:

[0015] 1. Select 9 pieces of N type single crystal silicon wafers as samples.

[0016] 2. The silicon wafer is uniformly cleaned by removing the damaged layer and RCA method, and ultrasonically cleaning with deionized water (DIW) for 2 minutes between each step. The specific steps are as follows:

[0017] 1) Ultrasonic cleaning with acetone for 10 minutes;

[0018] 2) Ultrasonic cleaning with absolute ethanol for 10 minutes;

[0019] 3) Prepare a KOH solution with a concentration of 25%, and heat it in a water bath at 80°C for 20 minutes;

[0020] 4) with (29%) NH 4 OH:(30%)H 2 o 2 :DIW=1:1:5 Prepare cleaning solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com