A kind of ammonia gas sensor with nanocomposite material as sensing film

A nanocomposite material and ammonia gas sensor technology, applied in the field of ammonia gas sensor, can solve the problems of long response and recovery time, inability to achieve detection requirements, poor selectivity, etc., and achieve high temperature working conditions, good response reversibility, and processability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of the Fe2O3 nanorod / reduced graphene oxide composite sensing film comprises the following steps:

[0032] Prepare a graphene oxide aqueous solution with a concentration of 1mg / mL, then add ferric chloride hexahydrate, sodium hydroxide and cetyltrimethylammonium bromide, ferric chloride hexahydrate, graphene oxide, sodium hydroxide and hexadecyl The weight ratio of alkyltrimethylammonium bromide is 1:0.01:0.2:0.5. Stir and ultrasonically oscillate to fully mix, transfer to a hydrothermal kettle for microwave hydrothermal reaction at 100°C for 20 minutes, and the reaction product is centrifuged to remove water Annealing at 200° C. for 1 hour in a tube furnace to prepare ferric oxide nanorods / reduced graphene oxide composites, wherein the percentage of ferric oxide nanorods is 95%, and the percentage of ferric oxide nanorods is 95%. 100nm in diameter and 350nm in length.

Embodiment 2

[0034] Construction of the ammonia sensor

[0035] An ammonia gas sensor is composed of a sensing film, a pair of electrodes, and an insulating substrate, wherein the insulating substrate is made of ceramics, rectangular in shape and 1.5mm×1.0mm in size; the pair of electrodes is an interdigitated gold electrode; the sensing film is The sensing film described in embodiment 1; the forked gold electrode is fixed on the surface of the ceramic substrate, the sensing film is covered on the ceramic substrate between the forked gold electrode and the forked gold electrode, and there are leads on the forked gold electrode for transmit electrical signals.

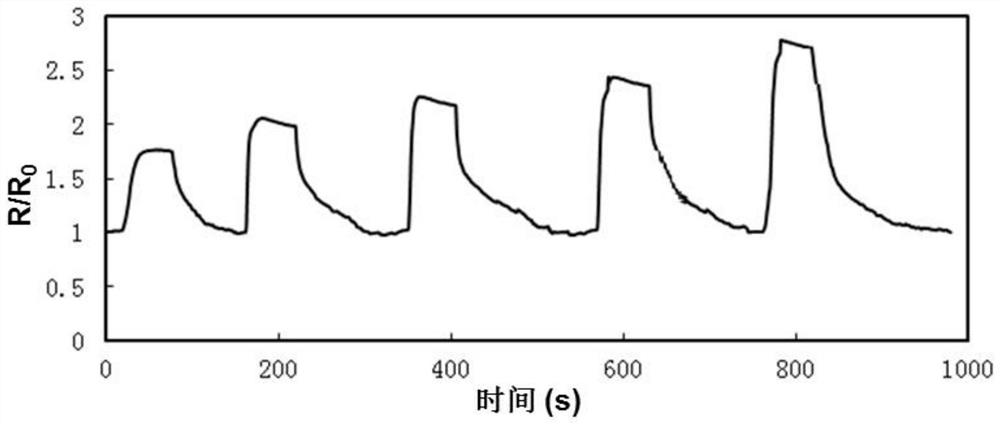

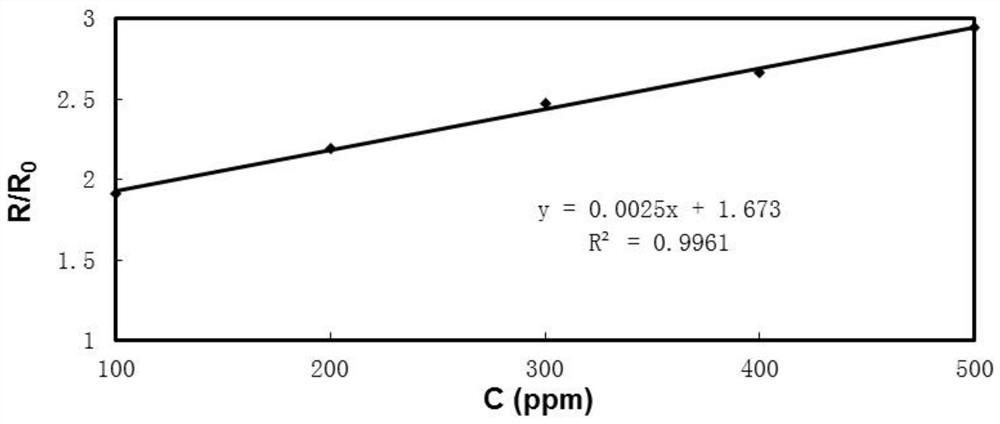

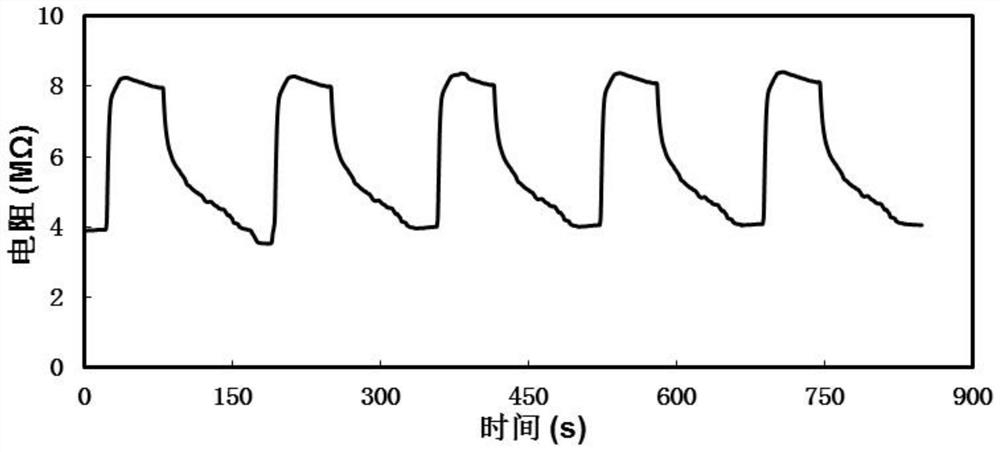

[0036] The ferric oxide nanorod / reduced graphene oxide composite material described in Example 1 was drop-coated on the surface of the interdigitated gold electrode with a ceramic substrate, and the thickness of the sensing film was 100 nm. A room-temperature ammonia sensor based on Fe2O3 nanorods / reduced graphene oxide composite w...

Embodiment 3

[0043]Preparation method as described in Example 1, wherein the weight ratio of ferric chloride hexahydrate, graphene oxide, sodium hydroxide and cetyltrimethylammonium bromide is 1:0.1:0.6:2, prepared The Fe2O3 nanorod / reduced graphene oxide composite material, wherein the percentage of the Fe2O3 nanorod is 50%, the diameter of the Fe2O3 nanorod is 300nm, and the length is 800nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com