Supported zinc-erbium co-doped bismuth ferrite photocatalyst and preparation method and application thereof

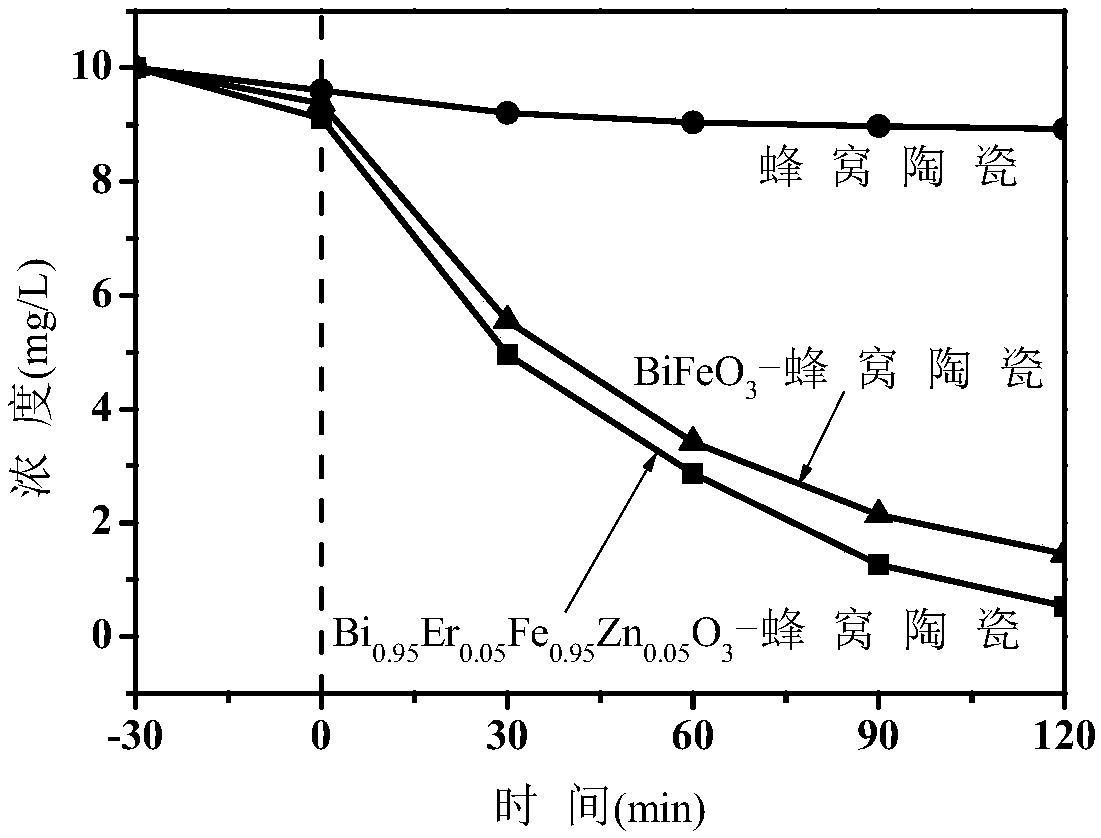

A photocatalyst and co-doping technology, which is applied in the field of photocatalytic materials, can solve the problems of unfavorable photocatalyst regeneration and reuse, poor stability of suspended catalysts, and difficult separation and recovery of photocatalysts, so as to increase photocatalytic reaction sites, Improvement of photocatalytic efficiency and enhancement of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Soak the honeycomb ceramic sample in 10% dilute nitric acid solution for 1 hour, take it out, rinse it with deionized water, dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 300°C for 3 hours, and set it aside. Dissolve a certain amount of ferric nitrate and zinc acetate in the mixed solution of 50mL absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid is 1:1) to obtain solution A, simultaneously a certain amount of bismuth nitrate and Erbium nitrate was dissolved in 50mL of a mixed solution of absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid was 1:1) to obtain solution B, and then slowly poured into solution B under rapid stirring at 800r / min. Drop all the A liquids to obtain solution C, so that the stoichiometric ratio of the zinc-erbium co-doped bismuth ferrite formed by ferric nitrate, bismuth nitrate, zinc acetat...

Embodiment 2

[0037] Soak the honeycomb ceramic sample in 10% dilute sulfuric acid solution for 1 hour, take it out and rinse it with deionized water, then dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 800°C for 0.5 hour, and set it aside. Dissolve a certain amount of ferric nitrate and zinc acetate in the mixed solution of 50mL absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid is 1:1) to obtain solution A, simultaneously a certain amount of bismuth nitrate and Erbium nitrate was dissolved in 50mL of a mixed solution of absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid was 1:1) to obtain solution B, and then slowly poured into solution B under rapid stirring at 800r / min. Drop all the A liquids to obtain solution C, so that the stoichiometric ratio of the zinc-erbium co-doped bismuth ferrite formed by ferric nitrate, bismuth nitrate, ...

Embodiment 3

[0039] Soak the copper foam sample in 10% dilute hydrochloric acid solution for 1 hour, take it out and rinse it with deionized water, then dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 600°C for 1 hour, and set it aside. Dissolve a certain amount of ferric nitrate and zinc acetate in the mixed solution of 50mL absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid is 1:1) to obtain solution A, simultaneously a certain amount of bismuth nitrate and Erbium nitrate was dissolved in 50mL of a mixed solution of absolute ethanol and glacial acetic acid (wherein the volume ratio of absolute ethanol and glacial acetic acid was 1:1) to obtain solution B, and then slowly poured into solution B under rapid stirring at 800r / min. Drop all the A liquids to obtain solution C, so that the stoichiometric ratio of the zinc-erbium co-doped bismuth ferrite formed by ferric nitrate, bismuth nitrate, zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com