Preparation method for graphene/copper composite nanosheet

A technology of nanosheets and graphene, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the shape of copper-based nanosheets is difficult to control, the copper-based nanosheets are easy to oxidize, and the performance is not good. Stability and other issues, to achieve the effect of short preparation cycle, good dispersion and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of graphene / copper composite nanosheet involved in the present invention comprises the following steps:

[0023] Step 1. Dissolving the copper-containing organic salt in an organic solvent whose boiling point is higher than the decomposition temperature of the organic salt is configured to form a decomposition solution.

[0024] Wherein the copper-containing organic salt is an organic salt containing monovalent or divalent copper, and the copper-containing organic salt is preferably copper oleate; the organic solvent having a boiling point higher than the decomposition temperature of the copper-containing organic salt is hydrocarbons, benzenes, One or more mixtures of ethers, long-chain alcohols, ketones, esters, and lipids, the organic solvent is preferably oleic acid; the copper concentration in the decomposition solution is preferably 0.001 mol / L-0.02mol / L.

[0025] Step 2, place the decomposition solution obtained in step 1 into a protective ...

Embodiment 1

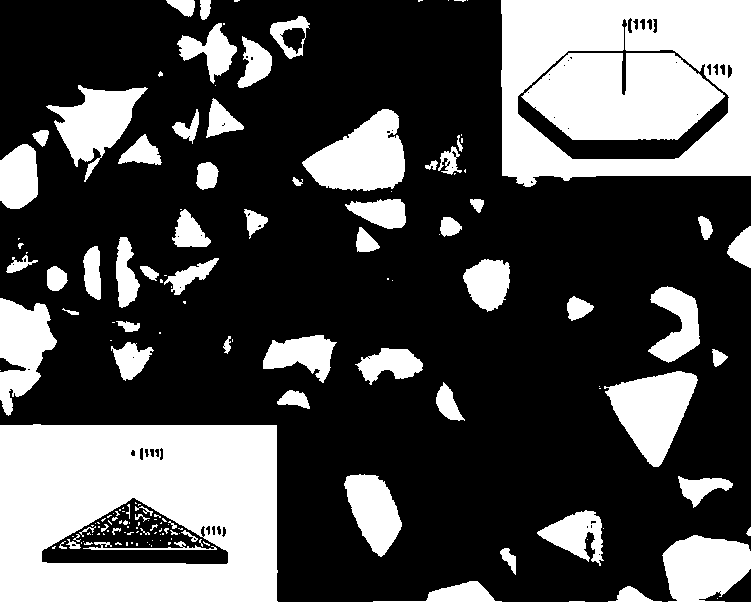

[0031] At room temperature, dissolve copper oleate containing divalent copper in oleic acid to make a decomposition solution with a copper concentration of 0.001mol / L; place the decomposition solution in a tube furnace and heat it under nitrogen protection. The gas flow rate is 60mL min -1 , the heating rate is 5°C / min. During the heating process, the maximum temperature of the decomposition solution is 250°C, and it is kept at 250°C for 30 minutes. Finally, nanosheets whose morphology is mainly regular triangles can be obtained.

[0032] After X-ray diffraction analysis, the sample has a strong diffraction peak on the Cu(111) plane. Through high-resolution transmission electron microscopy, the thickness of the nanosheets is 80nm-120nm, the average lateral size is 3μm-5μm, and the maximum lateral size is 10μm-14μm. The surface of the nanosheets is covered with a layer of graphene with 5-8 layers of crystal planes. Formation of graphene / copper composite nanosheets. The obtain...

Embodiment 2

[0036] At room temperature, dissolve copper oleate containing divalent copper in oleic acid to make a decomposition solution with a copper concentration of 0.001mol / L; place the decomposition solution in a tube furnace and heat it under the protection of argon. Argon gas flow rate is 80mL min -1 , the heating rate is 5°C / min. During the heating process, the maximum temperature of the decomposition solution is 250°C, and it is kept at 250°C for 30 minutes. Finally, nanosheets whose morphology is mainly regular triangles can be obtained.

[0037] After X-ray diffraction analysis, the sample has a strong diffraction peak on the Cu(111) plane. Through high-resolution transmission electron microscopy, the thickness of the nanosheets is 80nm-120nm, the average lateral size is 3μm-5μm, and the maximum lateral size is 10μm-14μm. The surface of the nanosheets is covered with a layer of graphene with 5-8 layers of crystal planes. Formation of graphene / copper composite nanosheets. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com