A compound type concrete antifreezer and a preparing method thereof

A concrete and antifreeze technology, applied in the field of building materials, can solve problems such as unstable quality and affecting concrete construction projects, and achieve the effects of improving application performance, enhancing antifreeze effect, and reducing water-binder ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

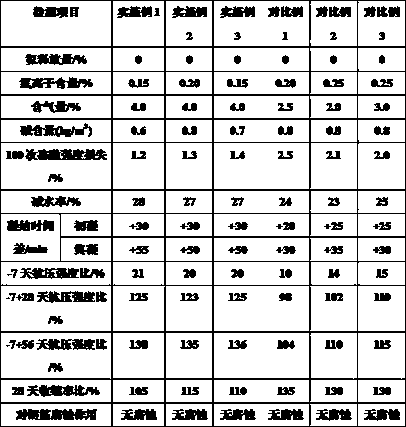

Examples

Embodiment 1

[0024] A composite antifreeze agent for concrete, which is prepared from the following raw materials in parts by weight: 45 parts of polycarboxylate water reducer, 16 parts of diethanol monoisopropanolamine maleate compound, 13 parts of lauroyl monoisopropanolamine Parts, 7 parts of diethylene triamine pentacarboxylate, 4 parts of sodium hexametaphosphate, 10 parts of sodium gluconate, 8 parts of N-methylolacrylamide, 3 parts of sodium tripolyphosphate, dinaphthyl methane disulfonic acid Sodium 4 parts, water 65 parts.

[0025] Described, diethanol monoisopropanolamine maleate compound is made by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, depressurize to 0.5MPa under stirring condition , heated to 95°C, keeping the system at a constant temperature, and the reaction stopped when there was no significant change in the acid value; naturally cooled to room temperature, washed with saturated sodium carbonate solution ...

Embodiment 2

[0035] A composite antifreeze agent for concrete, which is prepared from the following raw materials in parts by weight: 40 parts of polycarboxylate water reducer, 18 parts of diethanol monoisopropanolamine maleate compound, 15 parts of lauroyl monoisopropanolamine Parts, 8 parts of diethylene triamine pentacarboxylate, 3 parts of sodium hexametaphosphate, 12 parts of sodium gluconate, 6 parts of N-methylolacrylamide, 2 parts of sodium tripolyphosphate, dinaphthyl methane disulfonic acid Sodium 5 parts, water 60 parts.

[0036] Described, diethanol monoisopropanolamine maleate compound is made by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, depressurize to 0.5MPa under stirring condition , heated to 100°C, keeping the system at a constant temperature, and the reaction stopped when there was no significant change in the acid value; naturally cooled to room temperature, washed with saturated sodium carbonate solution...

Embodiment 3

[0046] A composite antifreeze agent for concrete is prepared from the following raw materials in parts by weight: 50 parts of polycarboxylate water reducer, 14 parts of diethanol monoisopropanolamine maleate compound, 10 parts of lauroyl monoisopropanolamine Parts, 6 parts of diethylene triamine pentacarboxylate, 5 parts of sodium hexametaphosphate, 8 parts of sodium gluconate, 10 parts of N-methylolacrylamide, 4 parts of sodium tripolyphosphate, dinaphthyl methane disulfonic acid 3 parts of sodium, 70 parts of water.

[0047]Described, diethanol monoisopropanolamine maleate compound is made by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, depressurize to 0.5MPa under stirring condition , heated to 90°C, kept the system at a constant temperature, and the reaction stopped when there was no significant change in the acid value; naturally cooled to room temperature, washed with saturated sodium carbonate solution and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com