A preparation method of zn-sba-15 composite material and its application in the synthesis of structural phospholipids

A technology of zn-sba-15 and composite materials, applied in the fields of applications, chemical instruments and methods, edible phospholipid compositions, etc., which can solve the problems of difficult recycling, limited reaction conditions, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

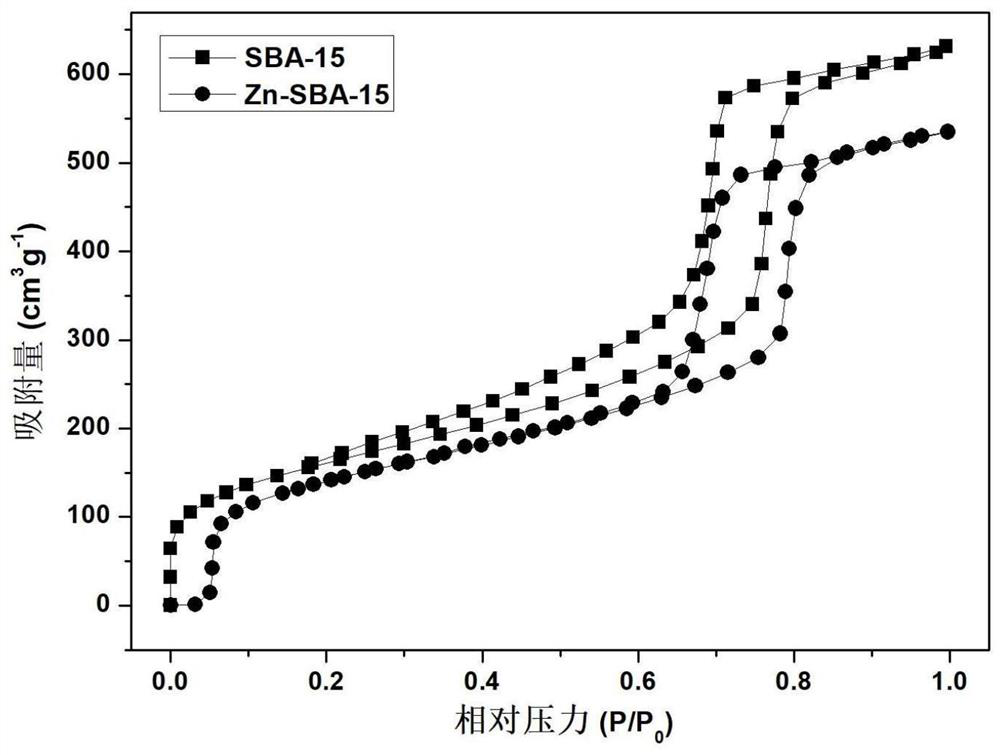

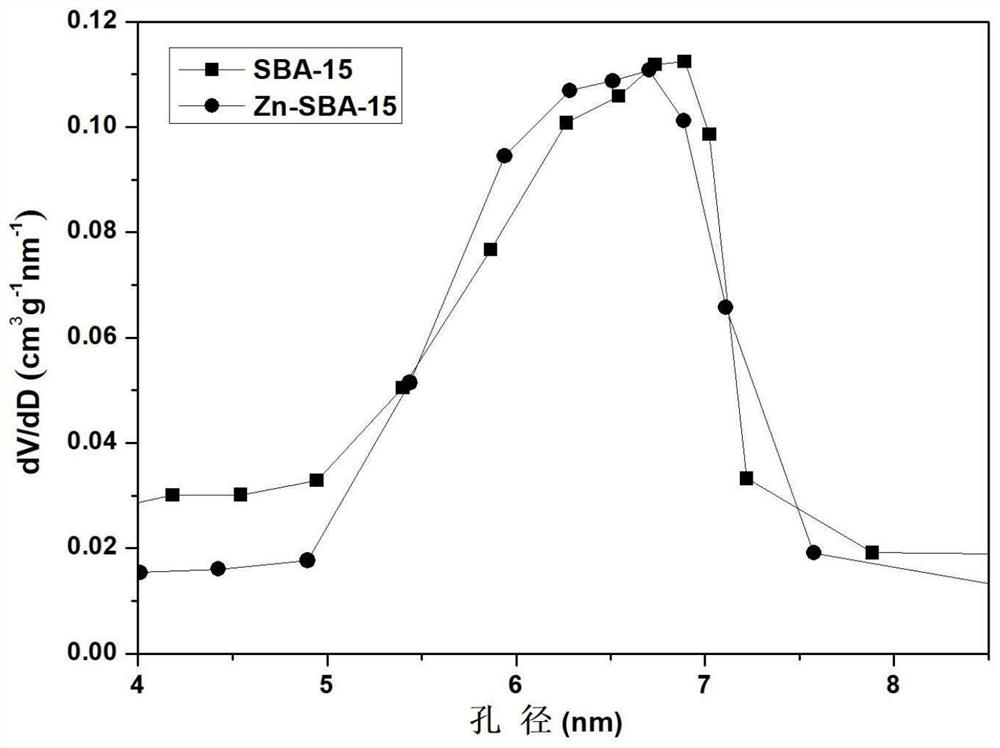

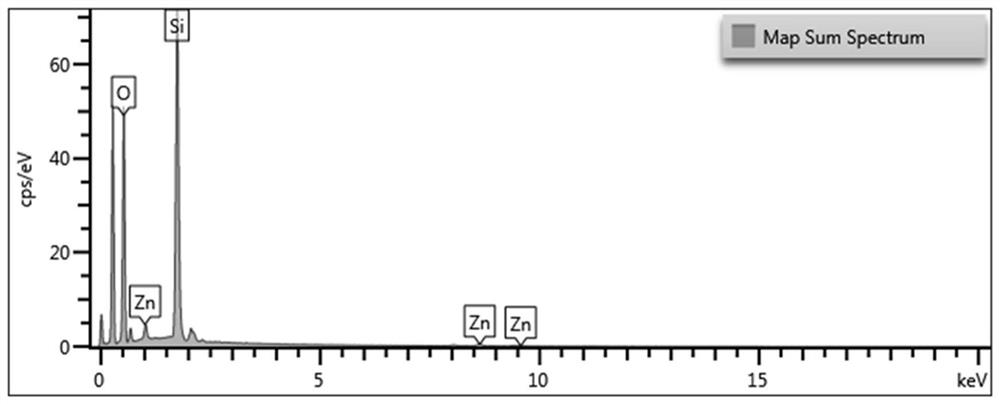

[0039] The technical purpose of the first aspect of the present invention is to provide a preparation method of SBA-15 and Zn-SBA-15 composite material, including the preparation method of SBA-15 molecular sieve and the step of metal zinc loading modification.

[0040] The technical purpose of the second aspect of the present invention is to provide a method for producing modified phospholipids, wherein the above Zn-SBA-15 composite material and natural phospholipids are subjected to a heterogeneous catalytic reaction of transesterification.

Embodiment 1

[0042] The preparation method of Zn-SBA-15 composite material, comprises the steps:

[0043] S1. Weigh SBA-15, zinc chloride, and anhydrous methanol according to the weight ratio of 23:1:1800, mix them evenly, stir for 12 hours, rotate at 600r / min, and filter with suction to get the precipitate, and filter with anhydrous methanol 12 times the weight of the precipitate Wash the obtained precipitate, and dry it for 6 hours under the conditions of vacuum degree -0.03MPa and temperature 30°C;

[0044] S2. Put the dried precipitate obtained in step S1 into a muffle furnace, and heat it at 5°C / min to 300°C for 9h to obtain a Zn-SBA-15 composite material.

[0045] Wherein, the preparation method of SBA-15 described in step S1 comprises the following steps:

[0046] S11. Weigh and mix the template agent P123, 1mol / L hydrochloric acid and deionized water according to the weight ratio of 4:28:7, stir at 40°C for 4 hours, and rotate at 1000r / min until the solution becomes clear;

[004...

Embodiment 2

[0059] The preparation method of Zn-SBA-15 composite material, comprises the steps:

[0060] S1. Weigh SBA-15, zinc sulfate and absolute ethanol and mix according to the weight ratio of 27:3:2200, stir for 24 hours at a speed of 1000r / min, filter with suction to obtain precipitate, and filter with anhydrous propanol 4 times the weight of the precipitate Wash the obtained precipitate, and dry it for 10 hours under the conditions of vacuum degree -0.01MPa and temperature 45°C;

[0061] S2. Put the dried precipitate obtained in step S1 into a muffle furnace, and heat it at 10° C. / min to 600° C. for 5 hours for calcination to obtain a Zn-SBA-15 composite material.

[0062] Wherein, the preparation method of SBA-15 described in step S1 comprises the following steps:

[0063] S11. Weigh the template agent F127, 3mol / L hydrochloric acid and deionized water according to the weight ratio of 2:10:3, mix them, stir at 70°C for 6h, and rotate at 1000r / min until the solution becomes clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com