A preparation method for regulating the molecular weight and distribution of poly(dimethylsiloxane-co-methylvinylsiloxane)

A technology of methyl vinyl siloxane and dimethyl siloxane, which is applied in the field of preparation of polymolecular weight regulation and control, can solve the problems of difficult control of molecular weight and wide molecular weight distribution, and achieves easy control of molecular weight and distribution, and preparation process. Simple, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

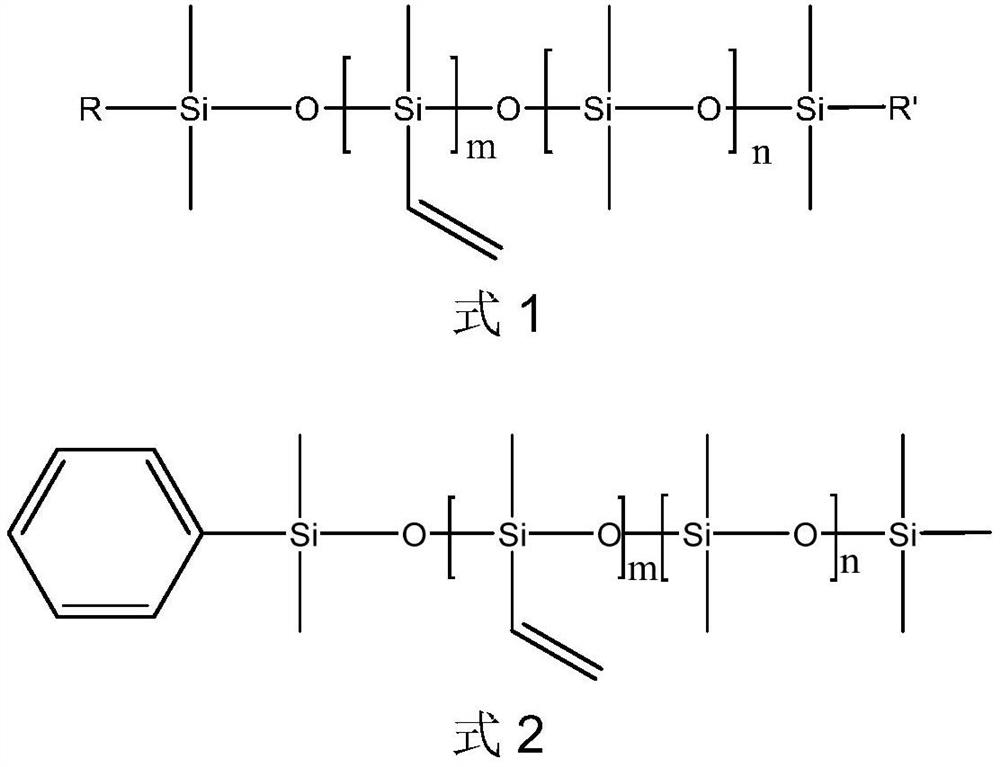

[0031] First, the two ring monomers, the base catalyst and the end-capping agent are purified. 5g (16.9mmol) octamethylcyclotetrasiloxane (D 4 ), 0.024g (0.187mmol) of potassium silanolate were placed in a four-necked flask equipped with a condenser, a stirrer, and a thermometer, and nitrogen gas was passed for 0.5h, and the temperature rose to 110°C for 2h of reaction, and then 5.8g (16.9mmol) Tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 0.368g (2.27mmol) hexamethyldisiloxane were added to the above reaction system, and the reaction was continued for 2h. The obtained crude product was purified in methanol, then centrifuged, and the methanol was removed by rotary evaporation, and finally a colorless and transparent viscous liquid was obtained, and the product was shown in Formula 1. Tested by GPC: Mn=7859; Mw / Mn=1.46. (Mw / Mn means molecular weight distribution)

Embodiment 2

[0033] First, the two ring monomers, catalysts and end-capping agents are purified. 3.76g (16.9mmol) hexamethylcyclotrisiloxane (D 3 ), 0.024g (0.187mmol) of potassium silanolate was put into a four-necked flask equipped with a condenser, a stirrer, and a thermometer, and nitrogen gas was passed for 0.5h, and the temperature rose to 110°C. After 2h of reaction, 5.8g (16.9mmol) of tetra Methyltetravinylcyclotetrasiloxane (D 4 Vi) and 0.368g (2.27mmol) of hexamethyldisiloxane were added to the above reaction system, and the reaction was continued for 2h. The obtained crude product was purified in methanol, then centrifuged, and the methanol was removed by rotary evaporation, and finally a colorless and transparent viscous liquid was obtained. Tested by GPC: Mn=6989; Mw / Mn=1.62.

Embodiment 3

[0035] First, the two ring monomers, catalysts and end-capping agents are purified. 5g (16.9mmol) octamethylcyclotetrasiloxane (D 4 ), 0.024g (0.187mmol) of potassium silanolate was placed in a four-necked flask equipped with a condenser, a stirrer, and a thermometer, and nitrogen gas was passed for 0.5h, and the temperature rose to 90°C. After 4h of reaction, 5.8g (16.9mmol) of four Methyltetravinylcyclotetrasiloxane (D 4 Vi ) into the above reaction system, reacted for 3h, then added 0.368g (2.27mmol) hexamethyldisiloxane, reacted for 2h, and stopped the reaction. The obtained crude product was purified in methanol, then centrifuged, and the methanol was removed by rotary evaporation, and finally a colorless and transparent viscous liquid was obtained. Tested by GPC: Mn=8288; Mw / Mn=1.55.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com