Process and catalyst for preparing 1,4-butanediol

A technology of catalyst and butanediol, which is applied in the fields of Raney-type catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., and can solve problems such as extremely high demand for nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Nickel foam commercially available in roll form with a thickness of 1.9 mm, a width of 300 mm, and an average pore diameter of 580 μm was sprayed with a commercially available adhesion promoter solution, coated with aluminum powder and heat-treated at 700°C. After cooling, the material thus obtained was laser cut into square pieces measuring 4 mm x 4 mm on a side and 1.9 mm thick.

[0055] The resulting bulk material was placed in a fixed bed for catalytic activation, followed by wet chemical treatment by pumping through 5M NaOH solution (sodium hydroxide in water). Part A of the bulk material was subjected to this wet chemical post-treatment at 70°C for 5 minutes. Part B of the bulk material was post-treated with aqueous sodium hydroxide solution at 60° C. for 15 minutes.

[0056] Both fractions were subsequently washed with water until the pH of the wash solution reached <10 after pumping through the fixed bed.

[0057] The composition of the two catalytically activ...

Embodiment 2

[0076] The catalyst was prepared as described in Example 1, wherein the wet chemical workup was carried out with 10% by weight aqueous sodium hydroxide solution at 60° C. for 60 minutes. The composition of the resulting catalytically active bulk material (Catalyst C) was analyzed by ICP-OES to give a composition of 89% by weight nickel and 11% by weight aluminum. The bulk density of the material d Sch =0.3kg / L. Bulk density was determined according to the procedure described in Example 1.

[0077] The catalytic efficiency of catalyst C for the hydrogenation of butyne-1,4-diol (BYD) to 1,4-butanediol (BDO) in a stirred tank reactor was also investigated. Experimental setup, procedures and evaluations were performed as described in Example 1.

[0078] The results are summarized in the table below:

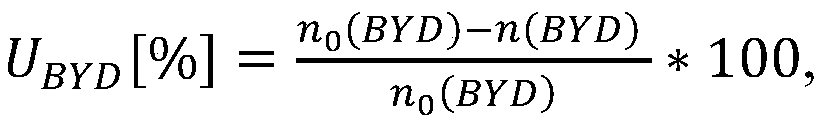

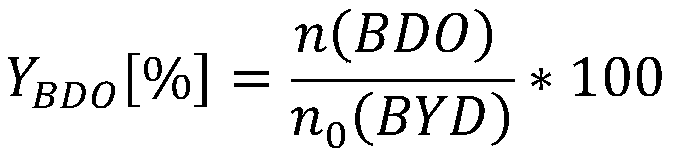

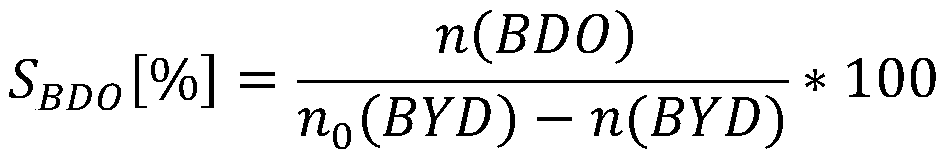

[0079] BYD conversion rate

BDO yield

BDO selectivity

STY BDO,V

97%

90%

93%

1.37kg / (L cat*h)

[0080] From the bulk density of catalys...

Embodiment 3

[0084] The catalyst was prepared as described in Example 1, wherein the wet-chemical workup was carried out with 10% by weight aqueous sodium hydroxide solution at 80° C. for 90 minutes. Molybdenum was precipitated on the catalyst from an aqueous molybdate solution after completion of the wet chemical treatment with aqueous sodium hydroxide. Analysis by ICP-OES gave a composition of the resulting catalytically active bulk material (Catalyst D) of 91% by weight nickel, 8.7% by weight aluminum and 0.3% by weight molybdenum. The bulk density of the material is d Sch =0.32kg / L. Bulk density was determined according to the procedure described in Example 1.

[0085] BDO Catalyst D was used in a pilot-scale fixed-bed reactor for the hydrogenation of 4-hydroxybutyraldehyde (HBA) to BDO at a temperature of 60 °C and a hydrogen pressure of 100 bar and showed almost quantitative conversion of HBA , which has very good BDO yield and BDO selectivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com