Ceramic tile made from desulfurized residues and glaze residues, and production method of ceramic tile

A production method and technology for ceramic bricks, applied in the field of ceramics, can solve the problems of difficult control of the shape and wave pattern of kiln bricks, low firing temperature of waste glaze slag, difficulty in high-quality antique bricks, etc., and simplify wastewater treatment equipment. , The decomposition temperature is easy to foam, and the effect of eliminating the discharge of production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

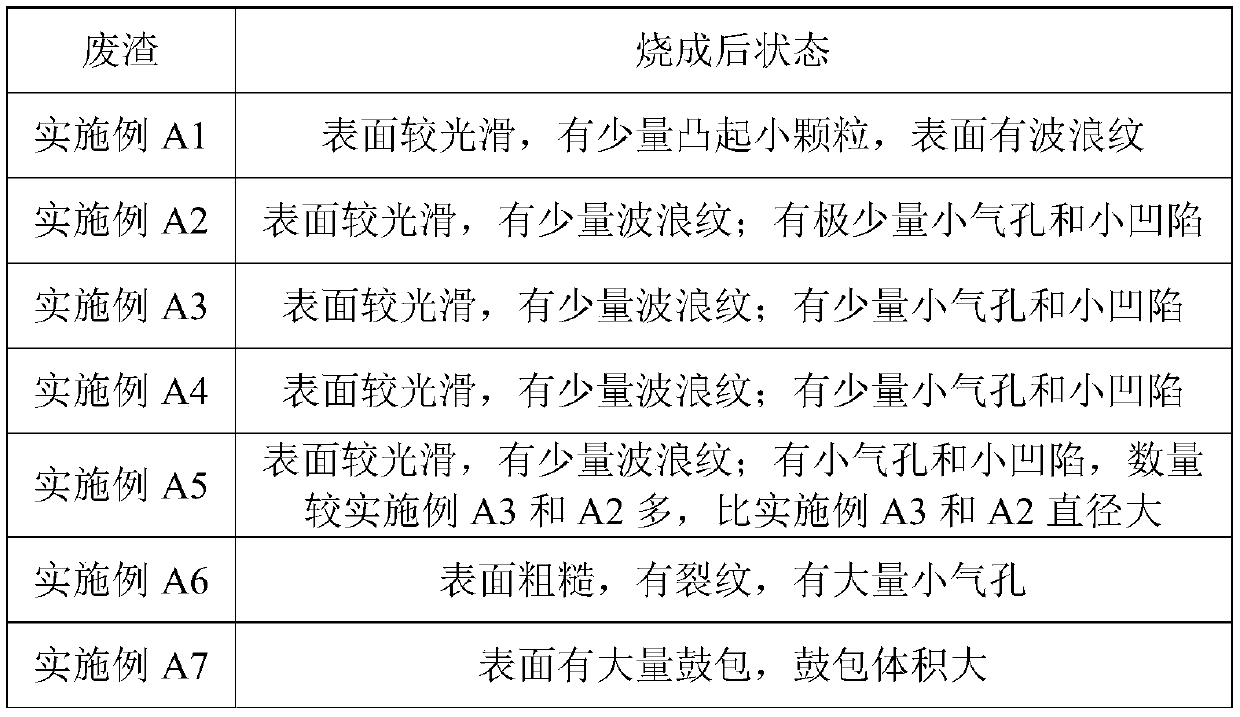

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the attached specific embodiments.

[0040] A ceramic brick using desulfurization slag and glaze slag as raw materials, the raw materials in weight percentage include: 1-5% of mixed waste slag, 95-99% of basic raw material; 75-90% of waste glaze in weight percentage of mixed waste slag slag and 10-25% desulfurization slag;

[0041] The waste glaze slag is the waste glaze slag produced during the production of ceramic tiles, and the desulfurization slag is the waste slag produced by desulfurizing flue gas with lime water.

[0042] The invention introduces waste glaze slag and waste slag produced by flue gas desulfurization into the basic formula, utilizes the characteristics of low melting point of waste glaze slag, high temperature melting degree, good fluidity, high decomposition temperature of desulfurization slag and easy foaming, and supplements desulfurization slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com