Water-based crosslinked epoxy anticorrosive coating based on wax modification and preparing method thereof

A technology of epoxy anti-corrosion coatings and waxy materials, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., and can solve the problem of recovery, flammable characteristics, safety hazards, anti-rust oils that cannot achieve long-term anti-corrosion, and cannot achieve Anti-corrosion cycle and other issues, to achieve the effect of increasing anti-corrosion effect, good coloring effect, and improving anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A water-based cross-linked epoxy anti-corrosion coating based on wax modification, including 18 parts of epoxy resin, 3 parts of methyl ether, 4 parts of isooctyl alcohol, 12 parts of perbasic sulfonate, 6 parts of polyethylene wax, 5 parts of surfactant, 4 parts of diethanolamine, 5 parts of polyamine resin and crosslinking agent, fully mix the above materials, add 2 parts of carboxylic acid for neutralization reaction, and disperse the mixed material in 50 parts of water, The above parts are all by weight.

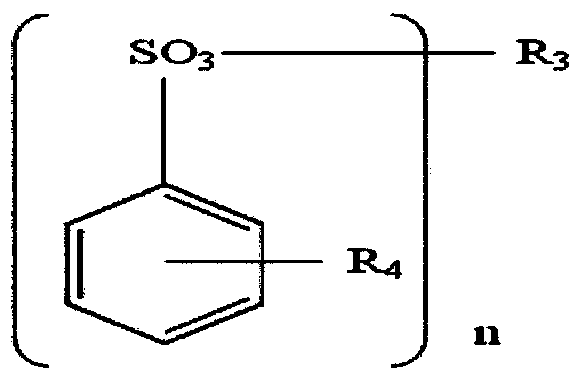

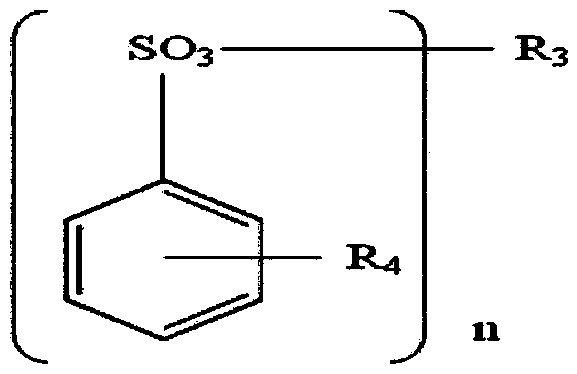

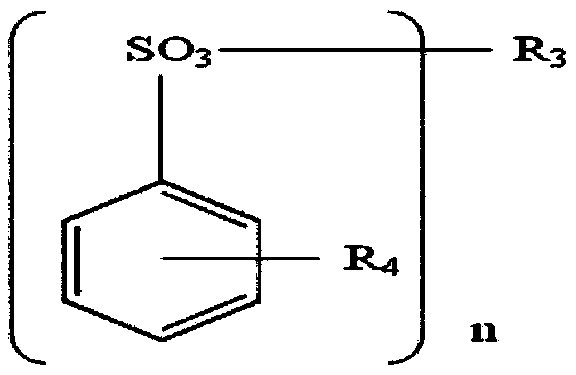

[0051] Specifically, the high alkali value sulfonate is shown in the following formula:

[0052]

[0053] Where: n=2;

[0055] R4 is C8-C30 isomeric branched chain alkyl;

[0056] The molecular weight of the overbasic sulfonate is 752, and the total base number of the overbasic sulfonate is 260 mgKOH / g.

[0057] Specifically, the waxy material is paraffin.

[0058] Specifically, the surfactant is fatty acid containing C8-C28 isome...

Embodiment 2

[0072] Compared with Example 1, the difference of Example 2 is that the crosslinking agent production process adopted is as follows:

[0073] A kind of production technology of linking agent I, comprises the following steps:

[0074] S1: Check the cleanliness of the reactor, the position of each pipeline and valve;

[0075] S2: 260 parts of toluene diisocyanate are vacuum pumped in, and 2.6 parts of organotin liquid are added while stirring;

[0076] S3: Pump 280 parts of ethylene glycol butyl ether into the metering tank, and when the material temperature rises to 60°C, add ethylene glycol butyl ether dropwise, and control the temperature at 60°C during the dropping process;

[0077] S4: After the dropwise addition of ethylene glycol butyl ether, react at a temperature of 68° C. for 1 hour, and add 180 parts of polyether;

[0078] S5: react at 90°C for 3.5 hours, add 280 parts of propylene glycol methyl ether at 65°C, stir evenly, discharge into a clean and dry airtight con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com