a preparation al 3 method of strengthening aluminum-based materials

A technology for strengthening aluminum-based and composite materials, which is applied in the field of metal smelting and extraction, and can solve problems such as the interface is easily oxidized or damaged, high production costs, and cumbersome procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

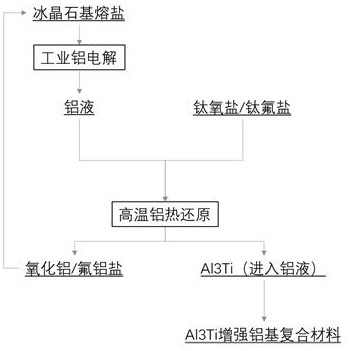

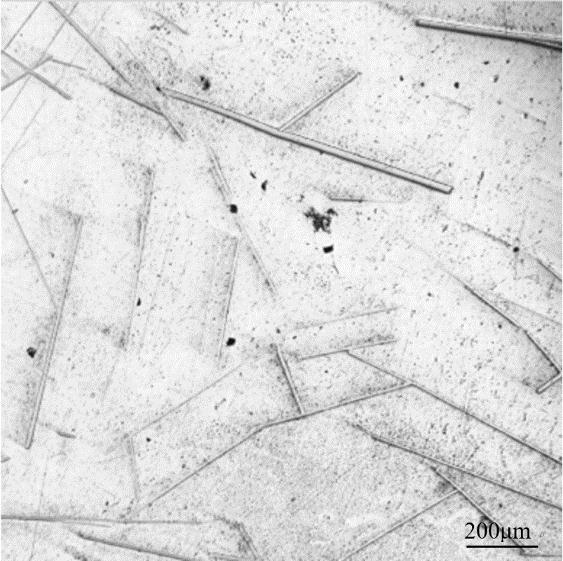

[0027] Example 1: see figure 2 and image 3 , a preparation of Al 3 Ti-reinforced aluminum-based material method, at 920-1000 ° C, dosing titanium oxide or titanium fluoride into the aluminum liquid, using metal aluminum as the reducing agent, aluminothermic reduction reaction occurs for 0.5-2h, the aluminothermic reduction process The reduced titanium further reacts with aluminum to form Al 3 Ti,Al 3 Ti enters the molten aluminum and distributes evenly to form Al 3 Ti-enhanced aluminum-based materials. During specific implementation, the reduction reaction temperature can be selected from 920°C, 930°C, 940°C, 950°C, 960°C, 970°C, 980°C, 990°C or 1000°C, and the reduction time can be selected from 0.5h, 0.8h, 1.0h, 1.2 h, 1.4h, 1.5h, 1.6h, 1.8h or 2h.

[0028] The Al 3 Ti-enhanced aluminum-based materials contain 2%≤Al by volume percentage 3 Ti≤25%. Specifically, Al 3 Al in Ti-reinforced aluminum-based materials 3 The volume percentage of Ti can be selected from 2%...

Embodiment 2

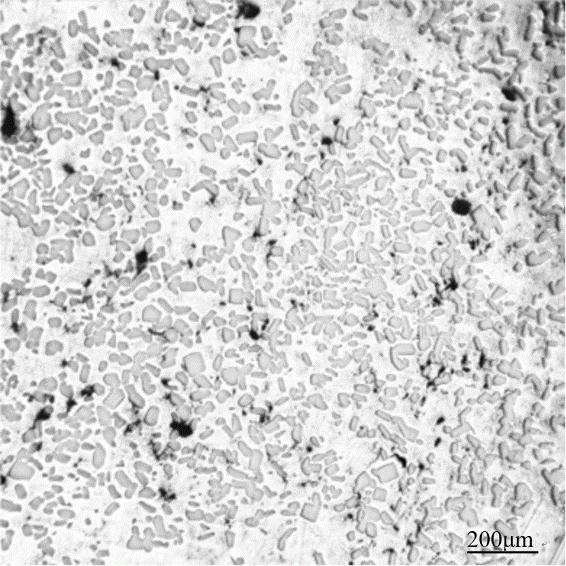

[0034] Example 2: see Figure 1 to Figure 3 , a preparation of Al 3 Ti strengthens the method for aluminum base material, is solvent with cryolite base molten salt, and aluminum oxide (aluminum oxide in this embodiment is Al 2 o 3 ) as the solute for electrolytic production of aluminum, adding titanium oxide or titanium fluoride to the cryolite-based molten salt, at 920-1000 ° C, using metal aluminum as the reducing agent, the aluminothermic reduction reaction occurs for 0.5-2h, aluminum The reduced titanium further reacts with aluminum to form Al during thermal reduction 3 Ti,Al 3 Ti enters the molten aluminum and distributes evenly, and the alloy and cryolite-based molten salt are separated to obtain Al 3 Ti reinforced aluminum matrix composites. During specific implementation, the reduction reaction temperature can be selected from 920°C, 930°C, 940°C, 950°C, 960°C, 970°C, 980°C, 990°C or 1000°C, and the reduction time can be selected from 0.5h, 0.8h, 1.0h, 1.2 h, 1.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com