Molten metal splashing protection fabric and production method thereof

A molten metal, manufacturing method technology, applied in the direction of textiles, papermaking, fabrics, textiles, etc., can solve the problems of molten metal splash without national product testing standards, poor resistance to molten metal impact, uneven product quality, etc., to improve the surface Effects of slipperiness and high temperature resistance, excellent flame retardancy, and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The molten metal splash protective fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns include 15% wool fibers, 45% flame-retardant viscose fibers, 25% aramid fibers, 10% nylon fibers, 5% % of conductive fibers, the sum of the five fiber mass percentages is 100%; the linear density of the above-mentioned warp and weft yarns includes the linear density of the warp yarns and the linear density of the weft yarns, the linear density of the warp yarns is 29tex, and the linear density of the weft yarns is 29tex. The density is 23tex×2; the fabric structure is five double-flying weft satin weaves, and the weight per unit area of the fabric is 250g / m 2 .

[0054] The above-mentioned molten metal splash protective fabric adopts the following weaving method, and the steps are as follows:

[0055] Step 1. Spinning: use wool fiber, flame retardant viscose fiber, aramid fiber, nylon fiber and conductive fiber as fiber raw materials...

Embodiment 2

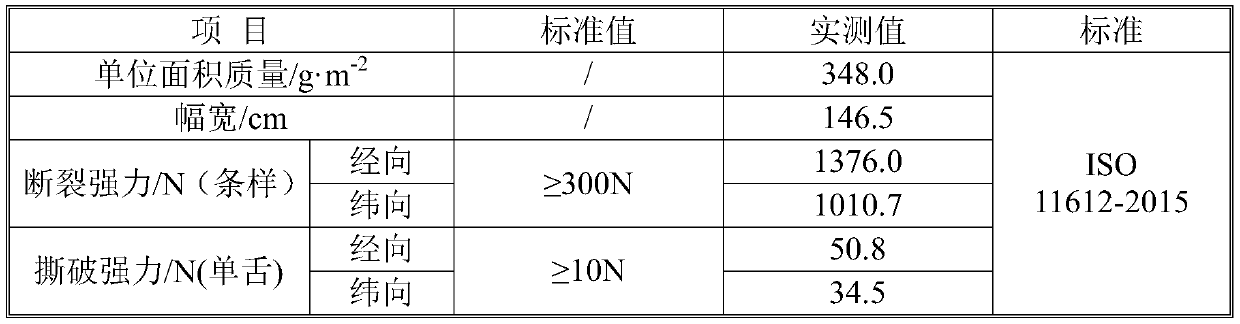

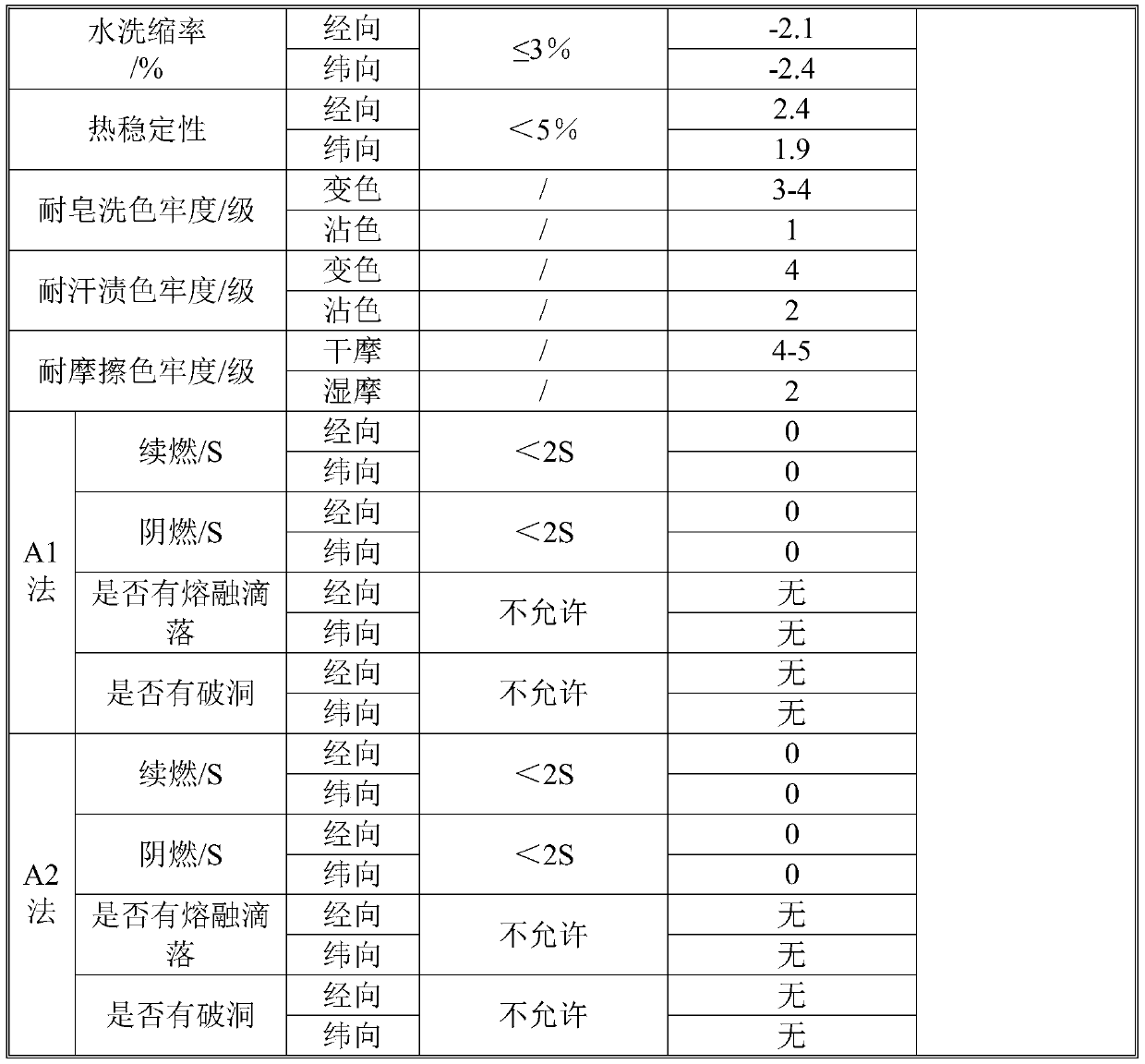

[0066] The molten metal splash protection fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns include 45% wool fibers, 35% flame-retardant viscose fibers, 15% aramid fibers, and 5% nylon fibers. The sum of the fiber mass percentages is 100%; the linear density of the above-mentioned warp and weft yarns includes the linear density of the warp yarns and the linear density of the weft yarns, the linear density of the warp yarns is 59tex, and the linear density of the weft yarns is 37tex × 2; The weave structure of the fabric is satin weave with six weft surfaces, and the mass per unit area of the fabric is 400g / m 2 .

[0067] The weaving method of this molten metal splash protection fabric is the same as embodiment 1, and the difference is:

[0068] The relevant parameters of the roving process are as follows: the total draft ratio is 10.00 times, the rear draft ratio is 2.25, the roving twist is 105 twist / m, and the spindle spe...

Embodiment 3

[0072] The molten metal splash protection fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns include 30% wool fibers, 40% flame-retardant viscose fibers, 20% aramid fibers, 8% nylon fibers, 2 % No conductive fiber, the sum of the five fiber mass percentages is 100%; the linear density of the above-mentioned warp and weft yarns includes the linear density of the warp yarns and the linear density of the weft yarns, the linear density of the warp yarns is 37tex, and the linear density of the weft yarns is 37tex. The density is 23tex×2; the fabric structure is five pieces of three-flying weft satin, and the weight per unit area of the fabric is 330g / m 2 .

[0073] The weaving method of this molten metal splash protection fabric is the same as embodiment 1, and the difference is:

[0074] The relevant parameters of the roving process are as follows: the total draft ratio is 8.00 times, the rear draft ratio is 1.25, the roving twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com