Submarine gas receiving facility with built-in heating pipe

A technology with built-in heating and receiving equipment, which is applied in the direction of mining fluid, earthwork drilling, reagents, etc., can solve problems such as natural gas leakage, achieve the effects of enhancing soil compactness, high safety and efficiency, and avoiding waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

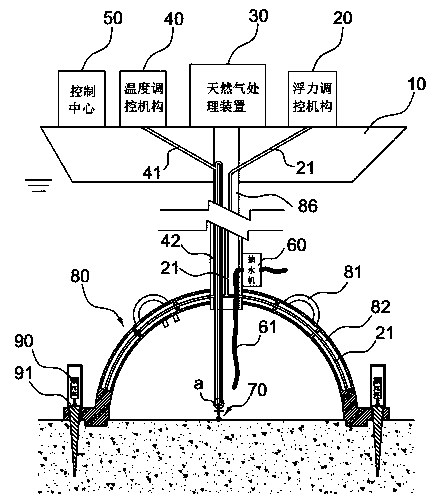

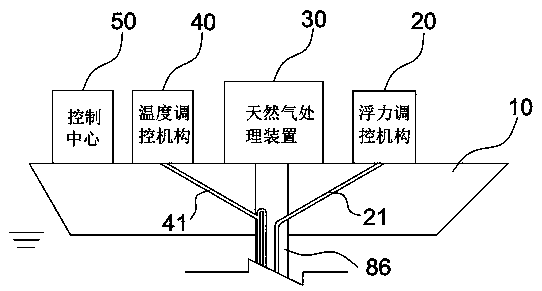

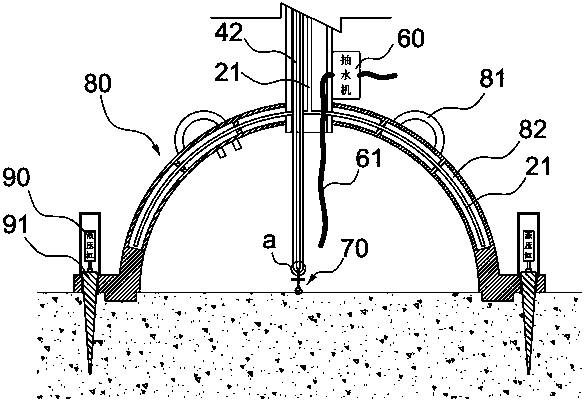

[0028] Such as Figure 1-6 As shown, the subsea natural gas receiving equipment with a built-in heating pipeline includes a gas collecting hood 80, which is connected to the natural gas processing device 30 on the hull 10 through a gas collecting pipe 86. The gas collecting hood 80 is a hemispherical hollow circular cover, and the gas collecting The side of the cover 80 is connected with a circular ring 83 on the same bottom surface. A hydraulic cylinder 90 that moves vertically up and down is surrounded on the circular ring 83. The output end of the hydraulic cylinder 90 is connected with an annular sealing body 91 that penetrates the circular ring 83. The sealing body 91 and the The area of the contact end of the hydraulic cylinder 90 is smaller than the area of the bottom end, and the bottom surface of the air collecting cover 80 inside the sealing body 91 is also provided with a protruding ring 84, and the protruding ring 84 is horizontally provided with through holes. ...

Embodiment 2

[0040] This embodiment further optimizes its technical scheme on the basis of Embodiment 1: a stirring mechanism 70 is connected to the bottom of the circulating pipe 42, and the stirring mechanism 70 includes a rotating shaft 71, and a rotating shaft 71 is vertically connected to the bottom end of the circulating pipe 42. Rotating blades 72 are set around the rotating shaft 71, the middle part of the rotating shaft 71 is provided with a supporting ring 73, the supporting ring 73 is horizontally connected with a supporting plate 74, and the surface of the supporting plate 74 is provided with a rectangular through hole, and one corner of the rectangular through hole is arc-shaped. The rest are right angles, and the bottom of the rotating shaft 71 is connected to the impeller 75 . The carbon dioxide gas flow flowing in the circulation pipe 42 is used to drive the rotating blade 72 to rotate, which saves the driving force for driving the rotating shaft 71 and saves energy consumpt...

Embodiment 3

[0042] The sealing body 91 of the present invention is prepared from rubber, and its specific preparation method is as follows:

[0043] Mixing: Take methyl vinyl silicone rubber raw rubber in parts by weight and put it into the open mill, slowly add fumed silica K-200, hydroxy silicone oil, and glyceryl caprylate during the open mill, and the whole process continues 0.5h, then continue to heat the ceramic filler, antimony hydroxide, silicon dioxide, high vinyl silicone oil and silane coupling agent, the whole process lasts for 0.5h, after the mixing is completed, the sheets are evenly produced;

[0044] High temperature treatment: Put the above compounded rubber in an electric blast drying oven at 178°C for 80 minutes, take it out and air cool for 24 hours;

[0045] Back refining: Put the cooled rubber compound after the above high-temperature treatment into the open mill again, add vulcanizing agent after 5 times of thinning, and continue thinning for 10 times to produce tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com