Glow plasma generation device applied to surface modification of high polymer material

A polymer material and surface modification technology, which is applied in the fields of plasma, electrical components, ultrasonic/sonic fiber processing, etc., can solve the limitation of surface modification effect improvement, high cost of nanosecond pulse power supply, and increase of electron avalanche severity, etc. problems, to avoid thermal instability effects, do not damage the performance of the body, and be easy to apply on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

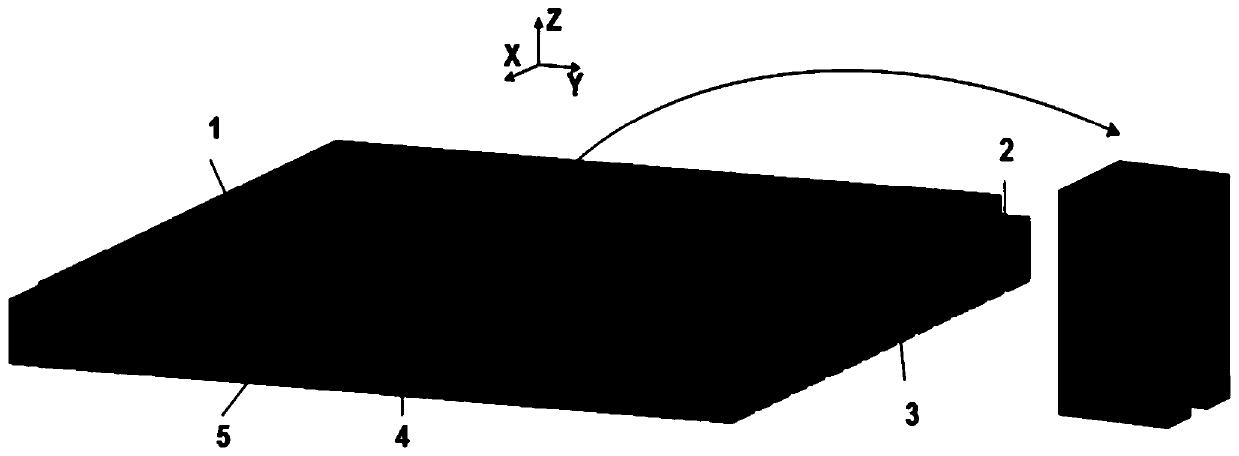

[0040] figure 1 It is a schematic structural diagram of a glow plasma generation device for surface modification of polymer materials provided by an embodiment of the present invention; figure 1 As shown, a glow discharge plasma generating device applied to the surface modification of polymer materials includes a high-voltage electrode 1, a high-voltage side insulating medium 2, a grounding electrode 3, a grounding side insulating medium 4, and a modified material 5; The upper surface of the high-voltage side insulating medium 2 is in close contact with the high-voltage electrode 1, and the lower surface of the high-voltage side insulating medium 2 is provided with several parallel and closely arranged grooves, the groove depth of which is less than 1mm; the ground electrode 3 is composed of a plurality of conductive wires, which are arranged in parallel and embedded in the ground-side insulating medium 4; the modified material 5 is placed between the high-voltage side insulat...

Embodiment 2

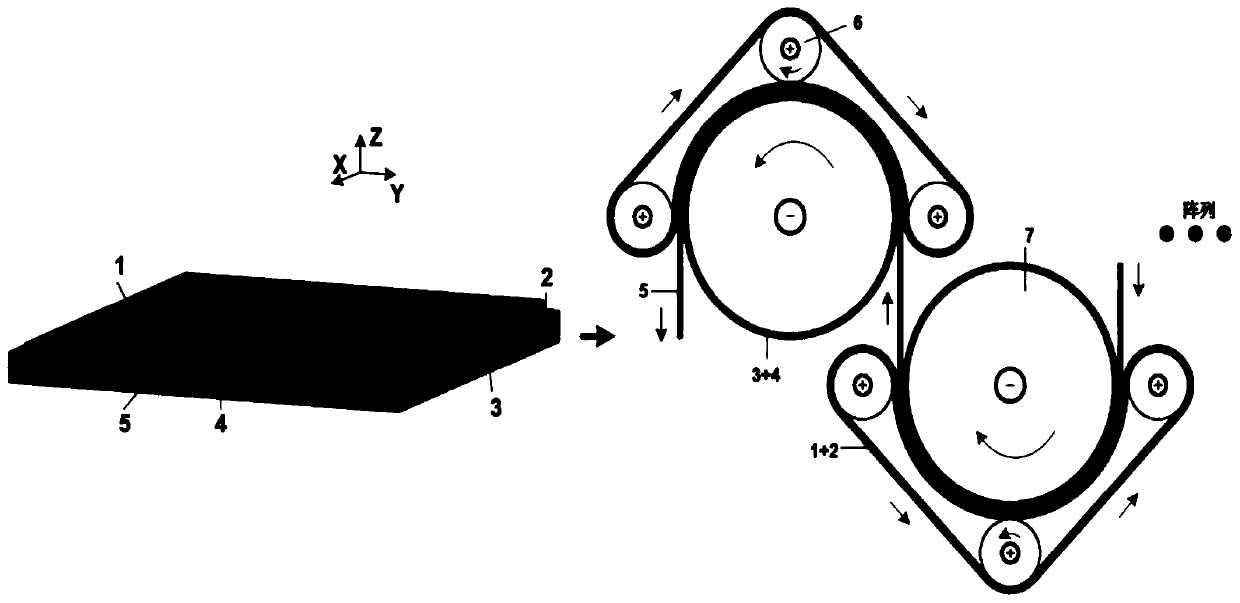

[0044] figure 2 It is a schematic structural diagram of another glow plasma generating device for surface modification of polymer materials provided by an embodiment of the present invention.

[0045] Such as figure 2 As shown, in the device provided in this embodiment, the high-voltage electrode is replaced by the metal flat electrode described in Embodiment 1 with a crawler type; the ground electrode is replaced by the flat electrode described in Embodiment 1 with a roller type; the crawler-type high-voltage electrode and the idler-type ground electrode constitute a set of modification devices.

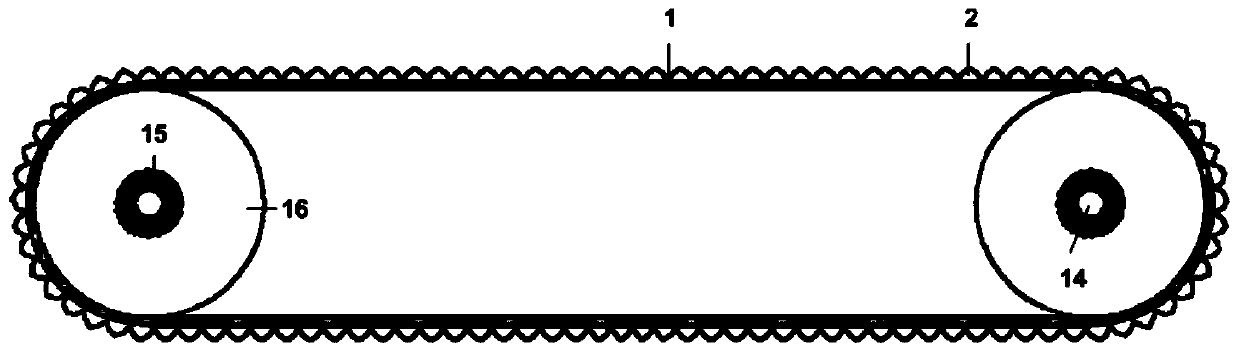

[0046] Such as image 3 As shown, the crawler-type high-voltage electrode includes a high-voltage side conductive roller 6, a high-voltage side conductive track 1, and a high-voltage side insulating medium 2; the high-voltage side conductive roller 6 is used to support the high-voltage side conductive track 1 and the high-voltage side insulating medium 2. The high-voltage side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com