A Mechanical Cryo-Trap Based on Moving Parts

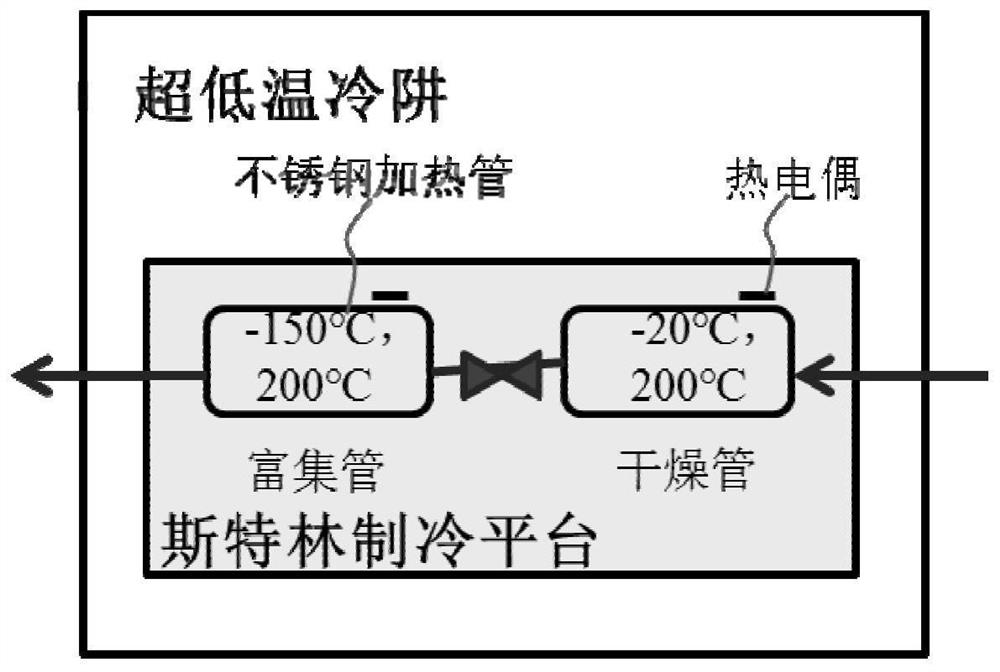

A low-temperature cold trap and moving parts technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of large energy consumption and heat leakage, low cooling and heating efficiency, bulky volume, etc., to reduce leakage Effect of heat loss and improvement of heating efficiency and enrichment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

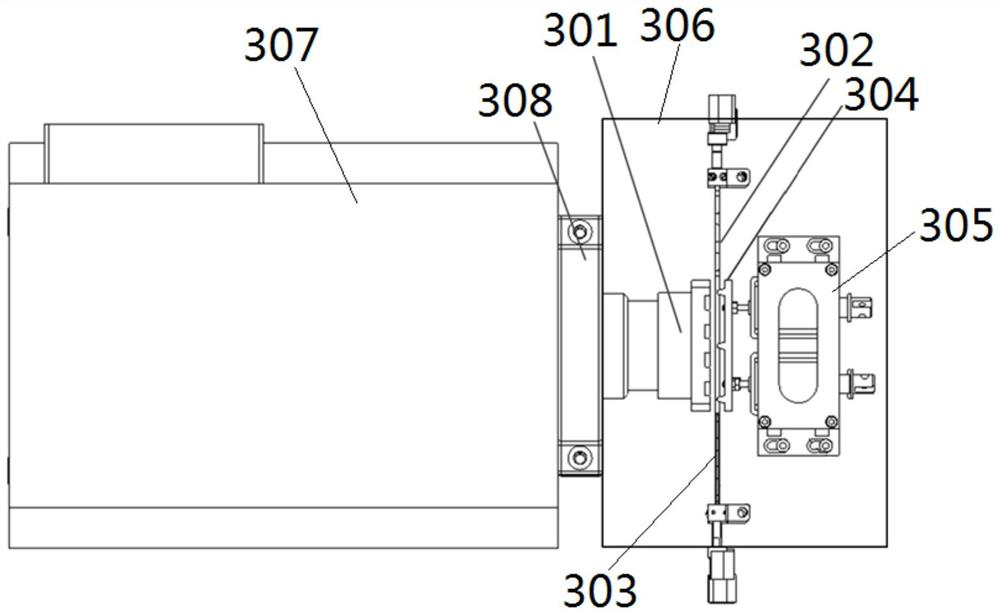

[0039] Such as image 3 and Figure 4 As shown, a mechanical cryogenic cold trap based on moving parts includes: cold head 301 , drying pipe 302 , enrichment pipe 303 , manipulator 304 , electric cylinder 305 and vacuum cover 306 . The cold head 301 , the drying pipe 302 , the enrichment pipe 303 , the manipulator 304 , and the electric cylinder 305 are all arranged in the vacuum cover 306 .

[0040] The cold head 301 uses the Stirling refrigerator 307 to provide a cold source, and the cold head of the existing Stirling refrigerator can be directly used. The Stirling refrigerator 307 is hermetically connected with the vacuum cover 306 through a vacuum flange 308 . The cold head 301 can directly use a copper block, and the cooling surface has a plate structure, which is convenient for cooling the drying pipe 302 and the enrichment pipe 303 .

[0041] Both the drying tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com