Polycrystal binder based on ardealite or building gypsum, preparation method and application

A technology of building gypsum and phosphogypsum, which is applied in the field of inorganic non-metallic materials and building materials, and can solve the problems of increasing, accumulative accumulation, and low utilization rate of phosphogypsum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

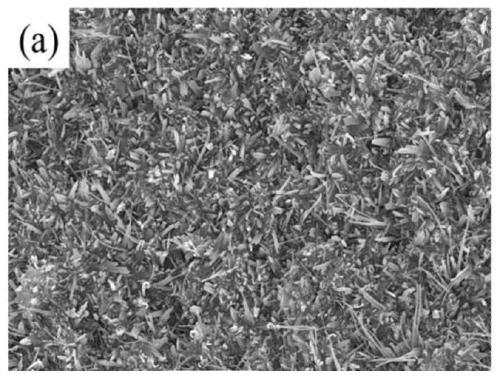

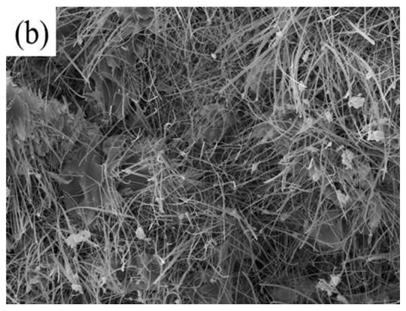

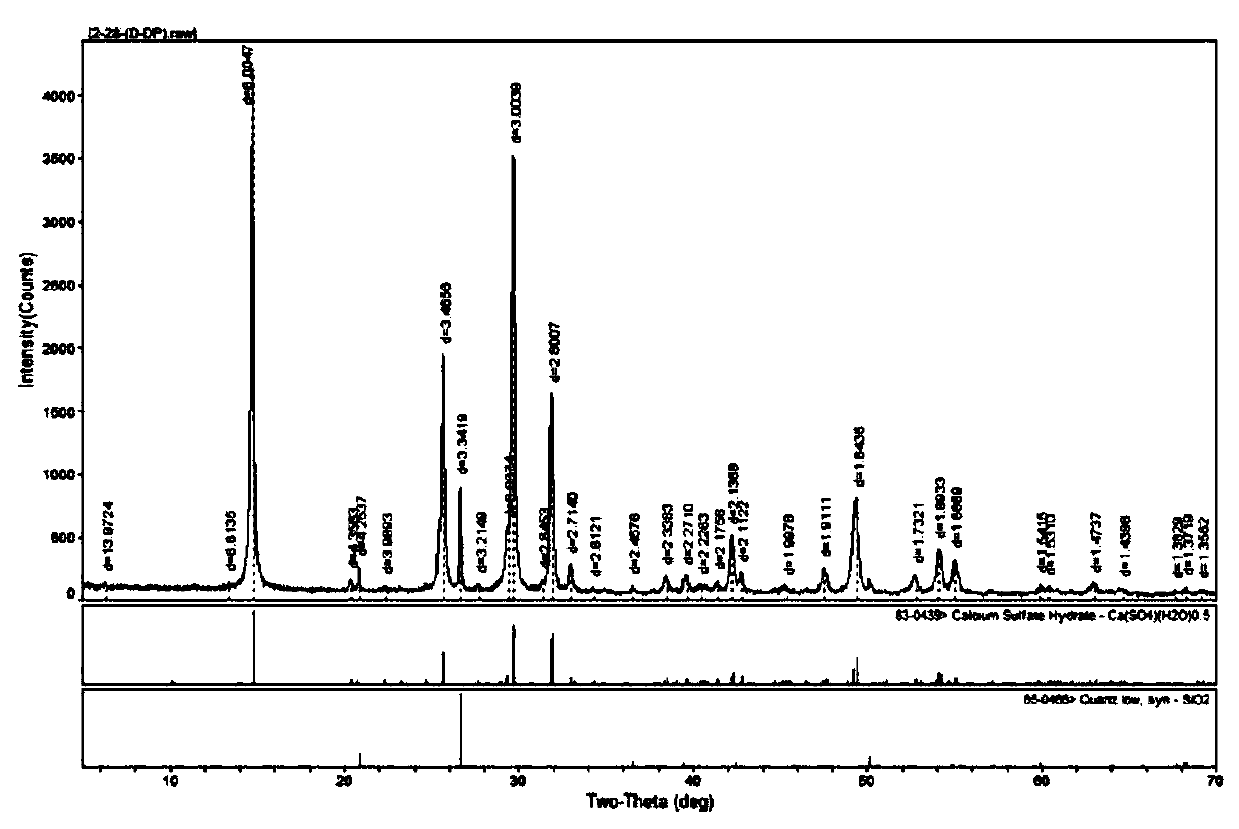

Image

Examples

Embodiment 1~ Embodiment 3

[0052] The phosphogypsum-based polycrystalline cement slurry in Examples 1 to 3 is prepared by mixing dehydrated phosphogypsum powder, light-burned magnesium oxide powder, halogen flakes and water. See Table 2 for its composition and proportion. Among them, dehydrated phosphogypsum powder was prepared in Comparative Example 1; light-burned magnesia was purchased from an enterprise in Haicheng City, Liaoning Province, and its chemical composition is shown in Table 3; magnesium chloride is a by-product of a seawater salt production enterprise in Tianjin-halogen flakes , its MgCl 2 ·6H 2 The O content is about 98%.

[0053] Composition and compounding ratio (mass %) of slurry in table 2 embodiment 1~3

[0054] Example

[0055] Table 3 Chemical composition of lightly burned magnesite powder

[0056] chemical composition

[0057]Examples 2 to 4 all use the "slurry preparation method" to mix the phosphogypsum-based polycrystalline cement slurry. After the slur...

Embodiment 4~ Embodiment 6

[0059] The phosphogypsum-based polycrystalline cementitious material powder in Examples 4 to 6 is prepared by mixing dehydrated phosphogypsum powder, light-burned magnesium oxide powder and halogen powder, and its composition and proportion are shown in Table 4. The selected dehydrated phosphogypsum powder, light-burned magnesium oxide powder, and halogen sheet are the same as those in Examples 1-3.

[0060] Composition and compounding ratio (mass %) of powder in table 4 embodiment 5~6

[0061] Example

Dehydrated Phosphogypsum

Halogen powder (MgCl 2 ·6H 2 O)

Example 4

39.5

36.1

24.4

Example 5

52.7

28.2

19.1

Example 6

61.4

23.1

15.5

[0062] The strength test results of phosphogypsum-based polycrystalline cement specimens in Table 5 Examples 2 to 6

[0063]

[0064] Examples 4-6 all use the "powder preparation method" to mix the three-component materials such as dehydr...

Embodiment 7~ Embodiment 9

[0066] The building gypsum-based polycrystalline cementitious material powder in embodiment 7~embodiment 9 is made of building gypsum powder, active MgO (chemically pure) and magnesium chloride tetrahydrate (MgCl 2 4H 2 O) and other three-component materials constitute, and its composition and proportioning are shown in Table 6. First, the "powder preparation method" is used to mix the three-component materials evenly to prepare polycrystalline cement powder.

[0067] Examples 7-9 all adopt the "slurry preparation method" to mix and prepare building gypsum-based polycrystalline cement paste. When mixing, the mass ratios of water and powder are 0.45, 0.42 and 0.40 respectively. After the slurry is evenly mixed, it is poured into cube and prism steel test molds, and cured in an environment of 25°C±2°C for 1 day. Remove the mold, put it in a plastic bag and continue curing at 25°C±2°C for 28 days, and test the strength of 1 day (d), 3 days and 15 days respectively. The test res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com