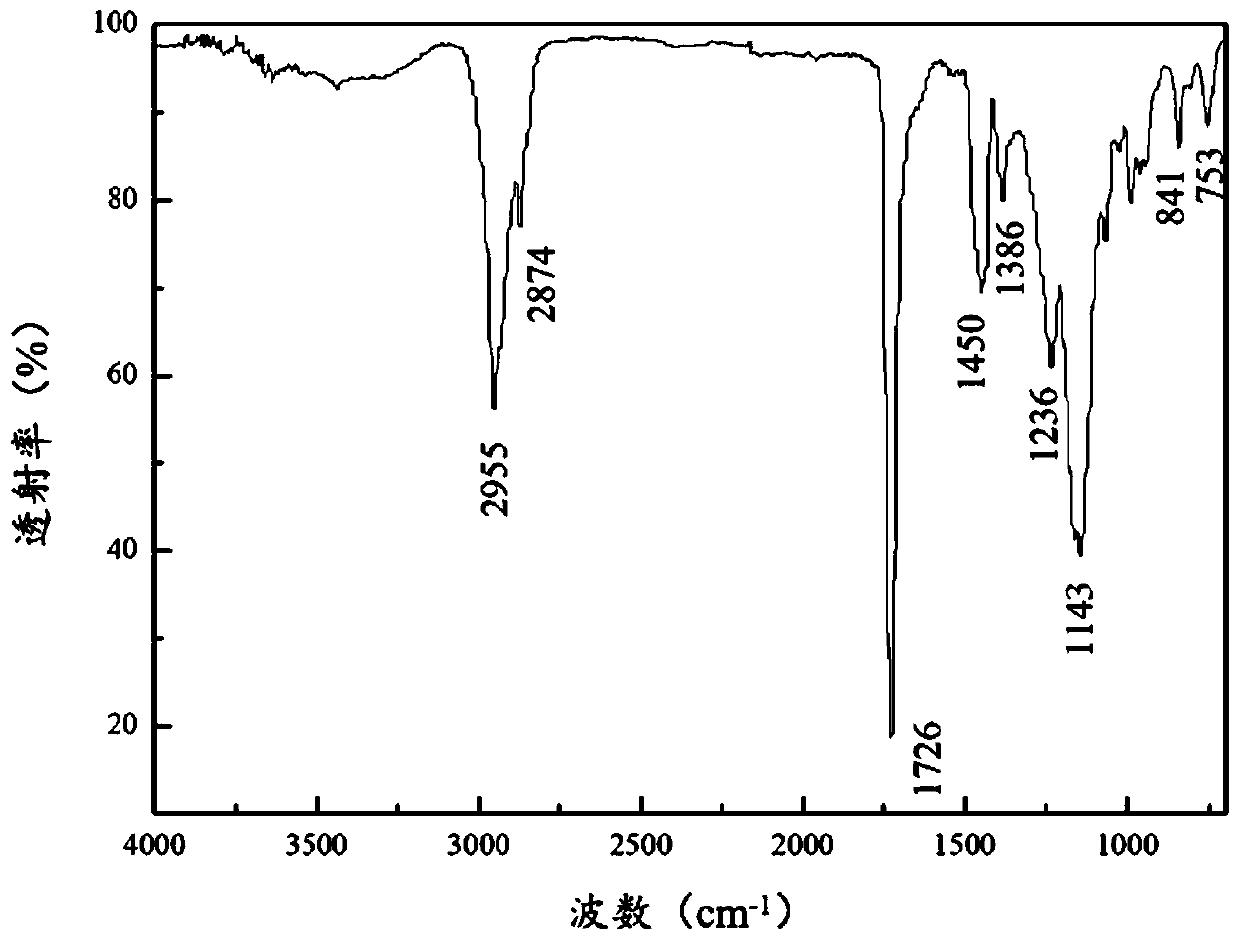

Long-chain monomer modified polyacrylic ester emulsion as well as preparation method and application thereof

A polyacrylate emulsion and acrylate technology, applied in the field of emulsions, can solve problems such as the preparation method and application of polyacrylate emulsions that are not involved, and achieve the effects of good biodegradability, low irritation and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 3.00g of fatty alcohol polyoxyethylene ether sulfosuccinic monoester disodium (AEMES), 0.3g of alkylphenol polyoxyethylene ether (OP-10) and 40.0g deionized water, stirred and heated to 80°C in a water bath. Add 3.0 g of mixed monomers of methyl methacrylate, butyl acrylate and octadecyl acrylate and 3.0 g of azobisisobutylamidine hydrochloride (V-50) aqueous solution dropwise within 15 minutes, and the addition is complete Then continue to keep warm for 15 minutes. Then the remaining 27.0g V-50 aqueous solution and 27.0g methyl methacrylate, butyl acrylate and octadecyl acrylate mixed monomers were added dropwise in the four-necked flask within 3.0h, and after the dropwise addition, the temperature was raised to 90 ℃, continue to keep warm for 40 minutes, then cool down to 40 ℃, after filtering and discharging, the long-chain monomer-modified polyacrylate emulsion is ob...

Embodiment 2

[0042] In a 250mL four-neck flask equipped with a stirrer, reflux condenser, and dropping funnel, add 2.4g of fatty alcohol polyoxyethylene ether sulfosuccinic monoester disodium (AEMES), 0.48g of alkylphenol polyoxyethylene Ether (OP-10) and 37.12g of deionized water, stirred and heated to 80°C in a water bath. Add 3.0 g of mixed monomers of methyl methacrylate, butyl acrylate and octadecyl acrylate and 3.0 g of azobisisobutylamidine hydrochloride (V-50) aqueous solution dropwise within 15 minutes, and the addition is complete Then continue to keep warm for 15 minutes. Then the remaining 27.0g V-50 aqueous solution and 27.0g methyl methacrylate, butyl acrylate and octadecyl acrylate mixed monomers were added dropwise in the four-necked flask within 3.0h, and after the dropwise addition, the temperature was raised to 90 ℃, continue to keep warm for 40min. The temperature was lowered to 40° C., and the long-chain monomer-modified polyacrylate emulsion was obtained after filte...

Embodiment 3

[0045] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 2.0 g of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.6 g of alkylphenol polyoxyethylene ether (OP-10) and 37.4g of deionized water, stirred and heated to 80°C in a water bath. Add 3.0 g of mixed monomers of methyl methacrylate, butyl acrylate and octadecyl acrylate and 3.0 g of azobisisobutylamidine hydrochloride (V-50) aqueous solution dropwise within 15 minutes, and the addition is complete Then continue to keep warm for 15 minutes. Then the remaining 27.0g V-50 aqueous solution and 27.0g methyl methacrylate, butyl acrylate and octadecyl acrylate mixed monomers were added dropwise in the four-necked flask within 3.0h, and after the dropwise addition, the temperature was raised to 90 ℃, continue to keep warm for 40min. The temperature was lowered to 40° C., and the long-chain monomer-modified polyacrylate emulsion was obtained after filtering out the m...

PUM

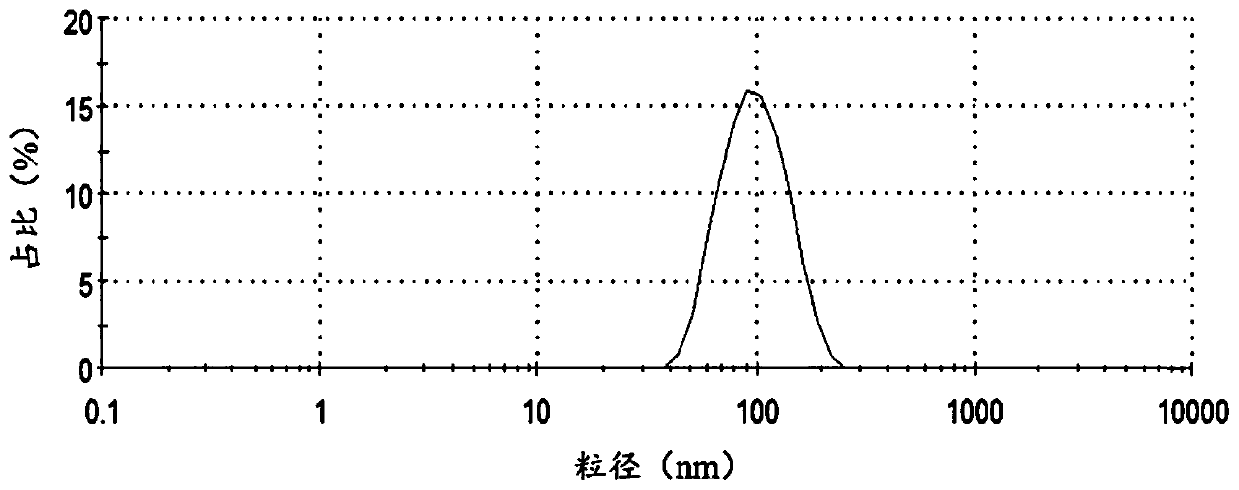

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com