Graphene-copper composite material preparation method

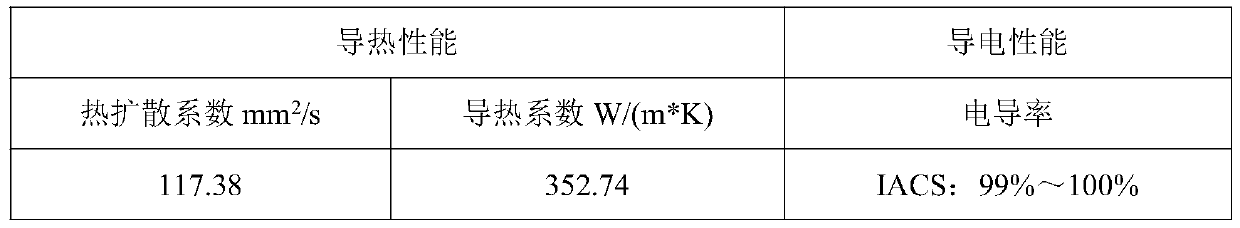

A composite material and graphene technology, which is applied in metal material coating technology, manufacturing tools, heat treatment equipment, etc., can solve problems such as uneven distribution, high probability of graphene agglomeration, and influence on metal material compounding, so as to improve mechanical properties , combined with the effect of compactness and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

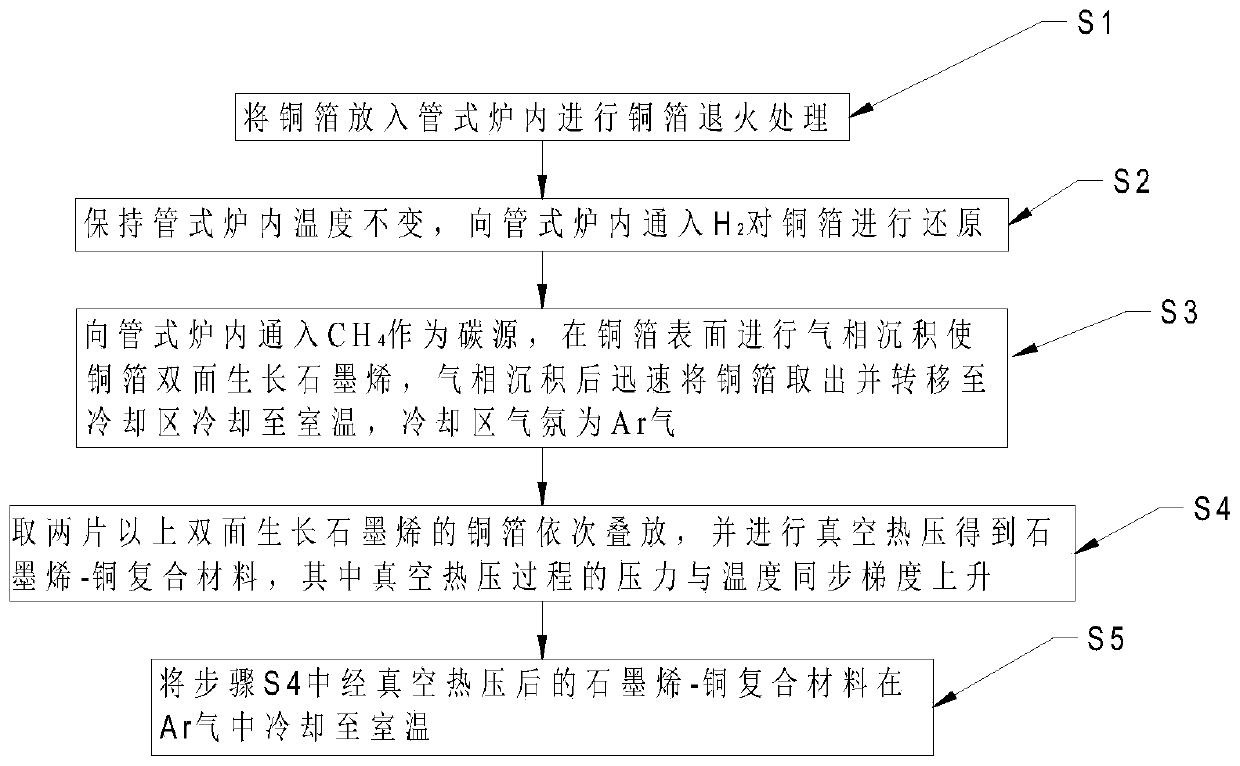

[0021] see figure 1 , a kind of graphene-copper composite material preparation method, comprises the steps:

[0022] S1: Put the copper foil into the tube furnace to anneal the copper foil;

[0023] S2: keep the temperature in the tube furnace constant, and pass H into the tube furnace 2 Reduction of copper foil;

[0024] S3: Introduce CH into the tube furnace 4 As a carbon source, vapor deposition is performed on the surface of the copper foil to grow graphene on both sides of the copper foil. After vapor deposition, the copper foil is quickly taken out and transferred to the cooling zone to cool to room temperature. The atmosphere in the cooling zone is Ar gas;

[0025] S4: Take two or more copper foils with double-sided graphene growth and stack them in sequence, and perform vacuum hot pressing to obtain a graphene-copper composite material, wherein the pressure and temperature of the vacuum hot pressing process increase synchronously;

[0026] S5: cooling the graphene-...

Embodiment 2

[0031] Take a copper foil with a thickness of 25um, anneal at 1000°C for 1h and 2 After reduction for 15min, CH was introduced at 1010°C 4 Vapor deposition as a carbon source, CH 4 The gas flow rate was 50 sccm, the vapor deposition time was 20 min, and then naturally cooled to room temperature in Ar.

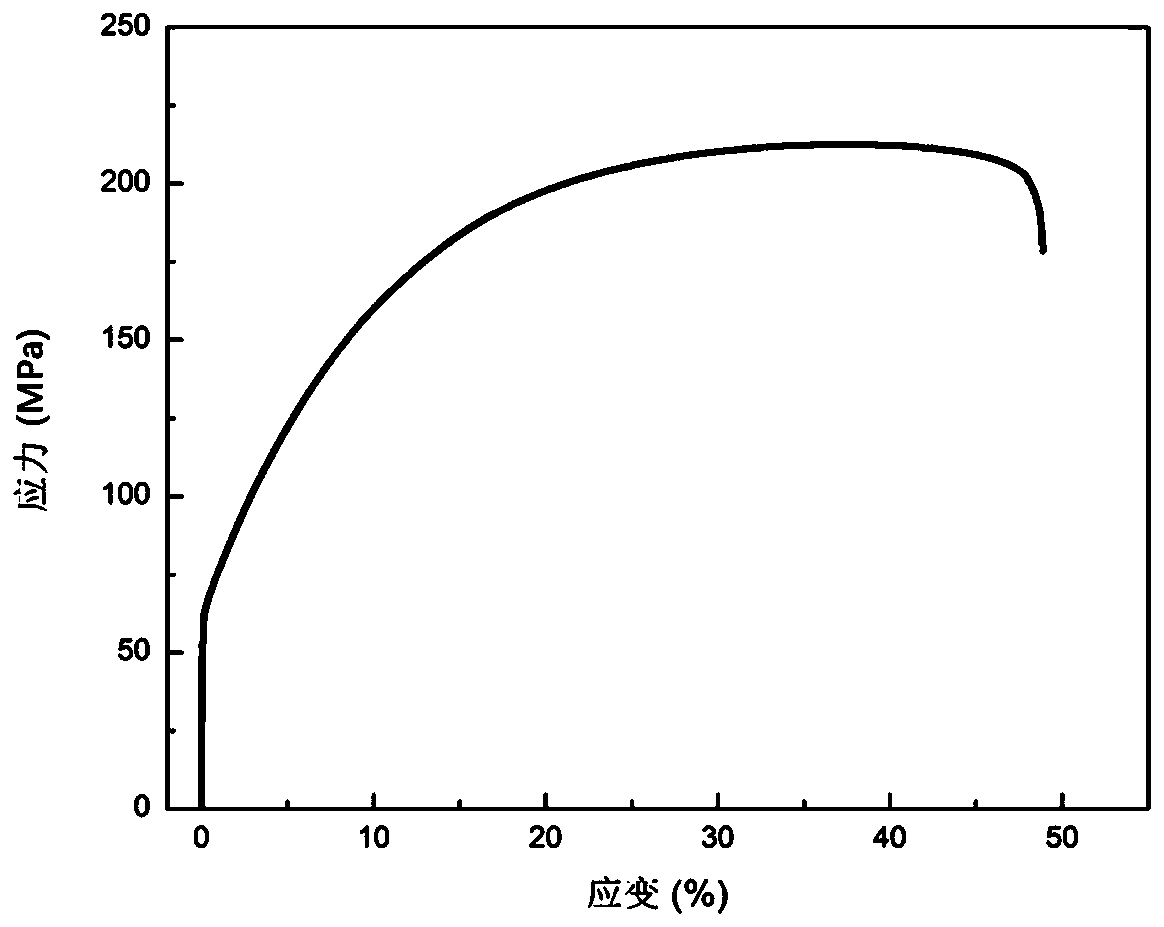

[0032] Take 15 pieces of copper foils treated by the above process to prepare graphene-copper composite materials by vacuum hot pressing. Start heating at 10°C / min to 200°C, keep the pressure constant, and keep warm for 1 hour; after the heat preservation, carry out a second rise in temperature, stop the temperature rise when the temperature rises to 1000°C, adjust the pressure to 40MPa at the same time, and keep warm for 1.5h. The thickness of the graphene-copper composite obtained after cooling is 0.87mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com