Method for identifying ultra-high-temperature sterilized milk and reconstituted milk based on lipid group

A technology of ultra-high temperature sterilization and reconstituted milk, which is applied in the field of food inspection, can solve the problems of loss of nutritional value, complicated processing, and long time consumption, and achieve the effect of high accuracy, simple processing method and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the pretreatment of sample

[0042]10 brands of ultra-high temperature sterilized milk and 10 brands of whole milk powder were purchased from major supermarkets in Beijing. Take 0.2 mL of milk samples in glass centrifuge tubes, add 1 mL of water, vortex for 5 min; add 3 mL of CHCl 3 : MeOH (2:1, V / V), vortex for 10min; centrifuge at 2000rpm for 15min; take the lower layer solution and blow with nitrogen; 2 Cl 2 : MeOH (2:1, V / V) reconstitution, take 1mL in the injection vial, as a lipid sample for the next step of detection;

[0043] Each sample was taken in parallel 5 times.

Embodiment 2

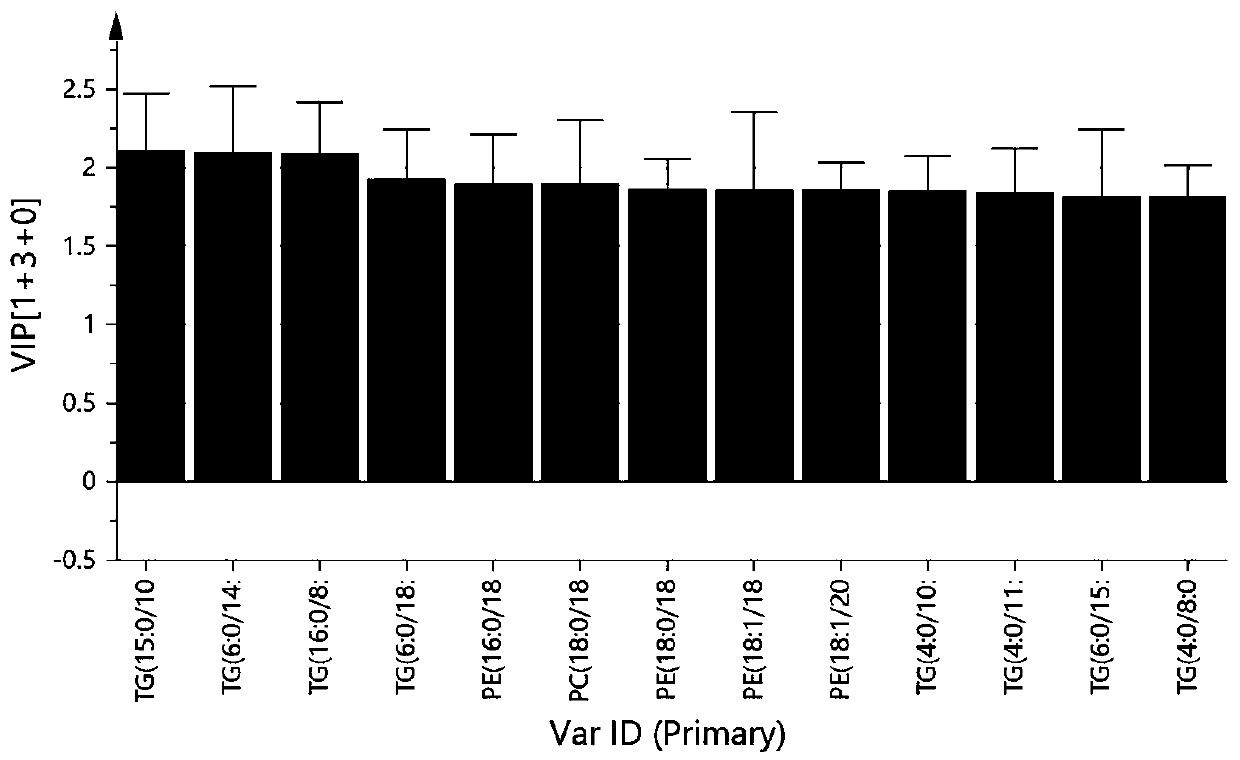

[0044] The integral area analysis of each characterization factor in two kinds of milks of embodiment 2:

[0045] 1) Detection by high-resolution mass spectrometry:

[0046] The high-resolution mass spectrometer model used in the experiment is UPLC-Q-Exactive orbitrap massspectrometer (Thermo, CA), the chromatographic column model used in positive and negative ion modes is XSelect CSH C18column, and the temperature of the column oven is 45°C.

[0047] After the sample is subjected to lipid extraction pretreatment, the lipid sample is subjected to chromatographic separation-high-resolution mass spectrometry analysis, and the mass spectrometry includes MS and MS / MS; the mobile phase A and mobile phase B used in the positive and negative ion modes are respectively containing 10mM ammonium acetate Acetonitrile:water (6:4 volume ratio), isopropanol:acetonitrile (9:1 volume ratio) containing 10mM ammonium acetate, the elution gradient is as follows:

[0048] step

total...

Embodiment 3

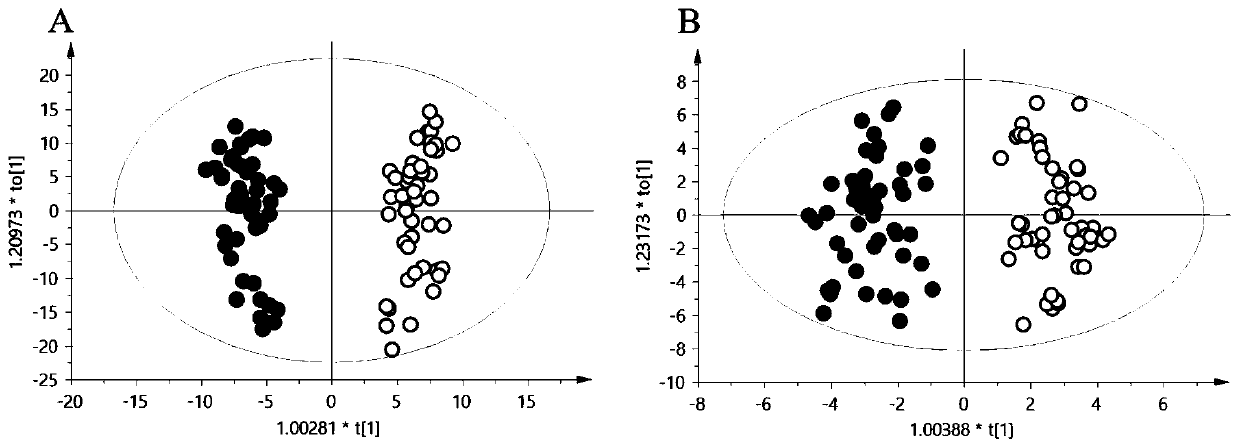

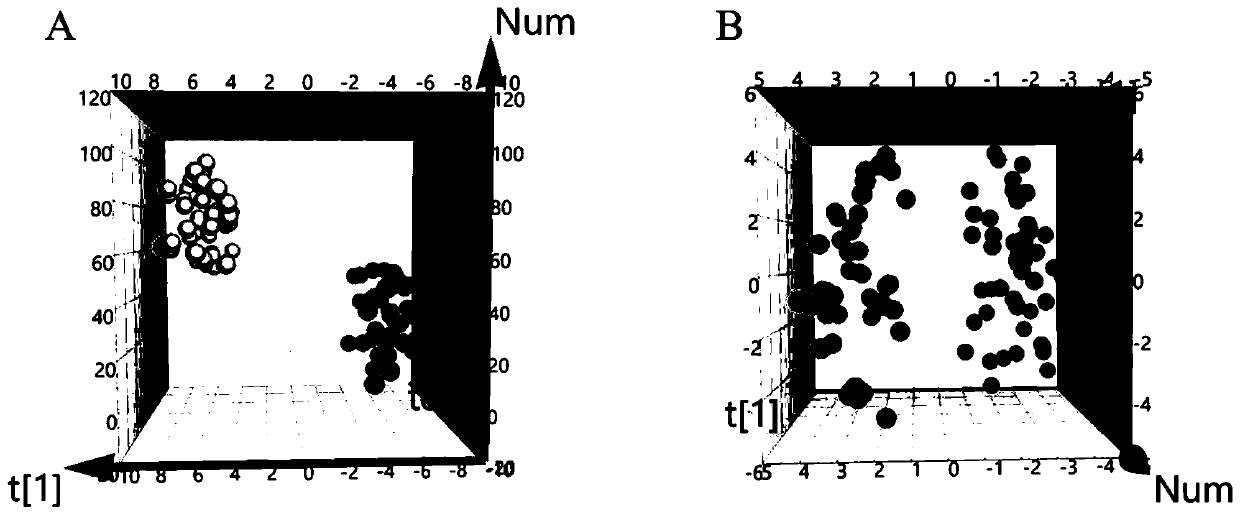

[0064] Use high-resolution mass spectrometry to detect lipid samples of unknown milk samples, extract the characterization factors that distinguish the two milks in the two modes under the positive and negative ion modes, and integrate the peak areas of the lipids in Tables 1 and 2 respectively, and the integral values Use the model established in Example 2 for discrimination. Specifically according to Figure 5 and Figure 6 , falling in the black dot area on the left is UHT milk, and falling in the gray dot area on the right is reconstituted milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com