S-doped carbon material supported Pt composite catalyst and preparation method and application thereof

A composite catalyst, carbon material technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor stability, low utilization rate of Pt, low catalyst activity, etc. The effect of high utilization rate, excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

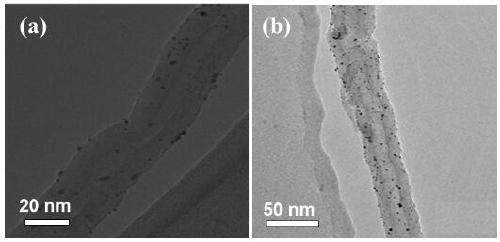

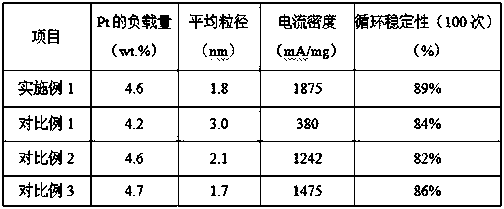

[0042] Example 1 Preparation of a S-doped carbon material supported Pt composite catalyst

[0043] Prepare S-doped carbon-supported Pt composite catalyst by the following method, comprising the following steps:

[0044] (1) Add carbon nanotubes and thiourea (mass ratio 1:1) to ethanol for ultrasonic mixing, and stir and heat the ultrasonically uniform mixture at 100°C until the solvent evaporates to dryness;

[0045] (2) The product of step (1) was dried and ground, calcined at 800°C for 3 h in an inert nitrogen gas, and taken out after cooling down in the tube furnace to obtain an S-doped carbon support;

[0046] (3) Loading precious metal Pt by impregnation method: Stir the S-doped carbon carrier in distilled water for ultrasonic dispersion, then add metal platinum salt precursor chloroplatinic acid, adjust the pH of the solution to 8.5 with KOH after ultrasonic stirring, and place it at a constant temperature of 60 °C Stirring for 1.5 h, cooling to room temperature, suctio...

Embodiment 2

[0048] Example 2 Preparation of a S-doped carbon material supported Pt composite catalyst

[0049] The preparation of S-doped carbon material loaded Pt composite catalyst comprises the following steps:

[0050] (1) Add carbon nanotubes and thiourea (mass ratio 0.25:1) to ethanol for ultrasonic mixing, stir and heat the ultrasonically uniform mixture at 70°C until the solvent evaporates to dryness;

[0051] (2) The product of step (1) was dried and ground, calcined at 700°C for 4 h in an inert nitrogen gas, and taken out after cooling down in the tube furnace to obtain an S-doped carbon support;

[0052] (3) Loading precious metal Pt by impregnation method: Stir the S-doped carbon carrier in distilled water and disperse it ultrasonically, then add the metal platinum salt precursor chloroplatinic acid, adjust the pH of the solution to 8.1 with KOH after ultrasonic stirring, and place it at a constant temperature of 55°C Stirring for 1 h, cooling to room temperature, suction fil...

Embodiment 3

[0054] Example 3 Preparation of a S-doped carbon material supported Pt composite catalyst

[0055] The preparation of S-doped carbon material loaded Pt composite catalyst comprises the following steps:

[0056] (1) Add carbon nanotubes and thiourea (mass ratio 4:1) to ethanol for ultrasonic mixing, and stir and heat the ultrasonically uniform mixture at 110°C until the solvent evaporates to dryness;

[0057] (2) The product of step (1) was dried and ground, calcined at 900°C for 2 h in an inert nitrogen gas, and taken out after cooling down in the tube furnace to obtain an S-doped carbon support;

[0058] (3) Loading noble metal Pt by impregnation method: Stir the S-doped carbon carrier in distilled water for ultrasonic dispersion, then add metal platinum salt precursor chloroplatinic acid, adjust the pH of the solution to 8.9 with KOH after ultrasonic stirring, and place it at a constant temperature of 65°C Stir for 2 h, cool to room temperature, suction filter, wash, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com