Superhard semiconductor amorphous carbon block material and preparation method thereof

A technology of bulk materials and semiconductors, applied in the application of ultra-high pressure process, etc., can solve the problems that have not been determined, the formation of amorphous carbon, phase transition and performance research are not yet fully clear, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the present invention is as follows:

[0031] (1) High-purity C 60 The fullerene powder is prefabricated into a cylindrical green body with a diameter of 1.2 or 2mm and a height of 2.3mm;

[0032] (2) Pack the cylindrical green body obtained in the hexagonal boron nitride crucible, and then pack in the high temperature and high pressure assembly block of standard 8 / 3 or the high temperature and high pressure assembly block of standard 10 / 5;

[0033] (3) Place the assembly block in a T25 ultra-high pressure temperature synthesis device for high temperature and high pressure treatment. The temperature of the high temperature and high pressure treatment is 500-2000 ° C, the pressure is 8-25GPa, and the holding time is 10-120 minutes;

[0034] (4) Obtain a superhard semiconductor amorphous carbon bulk material with a diameter of 1-1.9mm and a height of 1.2-1.7mm after the treatment is completed.

[0035] Compared with the prior art, the present i...

Embodiment 1

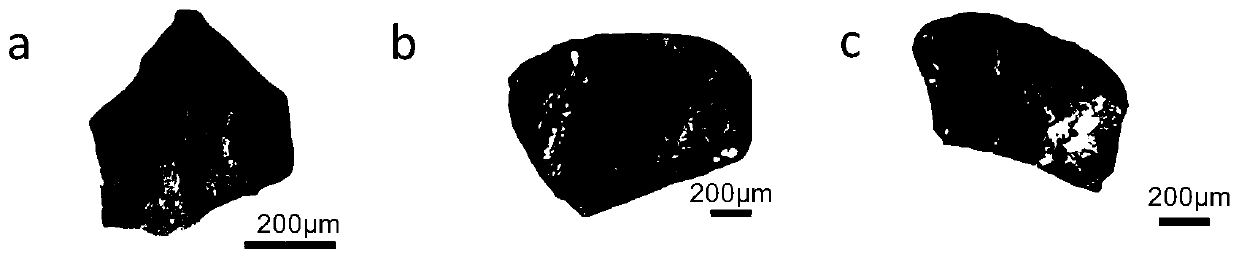

[0040] High-purity C produced by Alfa Aisha Chemical Co., Ltd. 60 The fullerene powder is prefabricated into a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, which is put into a hexagonal boron nitride crucible, and then loaded into a standard 8 / 3 high-temperature and high-pressure assembly block, and the assembly block is loaded into a T25 ultra- The high-pressure temperature synthesis device is heated for 120 minutes at a pressure of 25 GPa and a temperature of 1200 ° C. The synthesized transparent amorphous carbon block is as follows figure 1 As shown in a, its density is 3.4±0.1(g / cm 3 ).

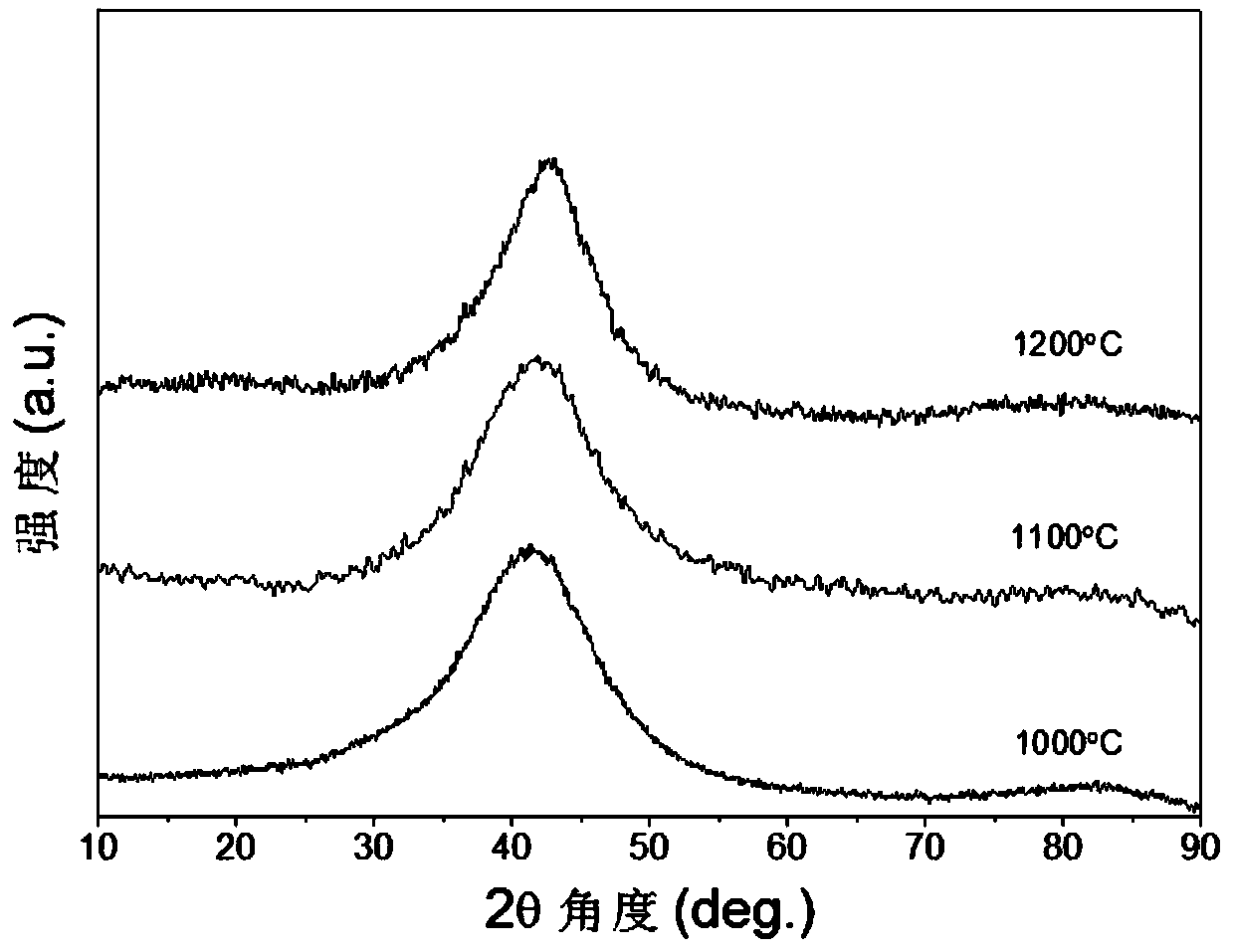

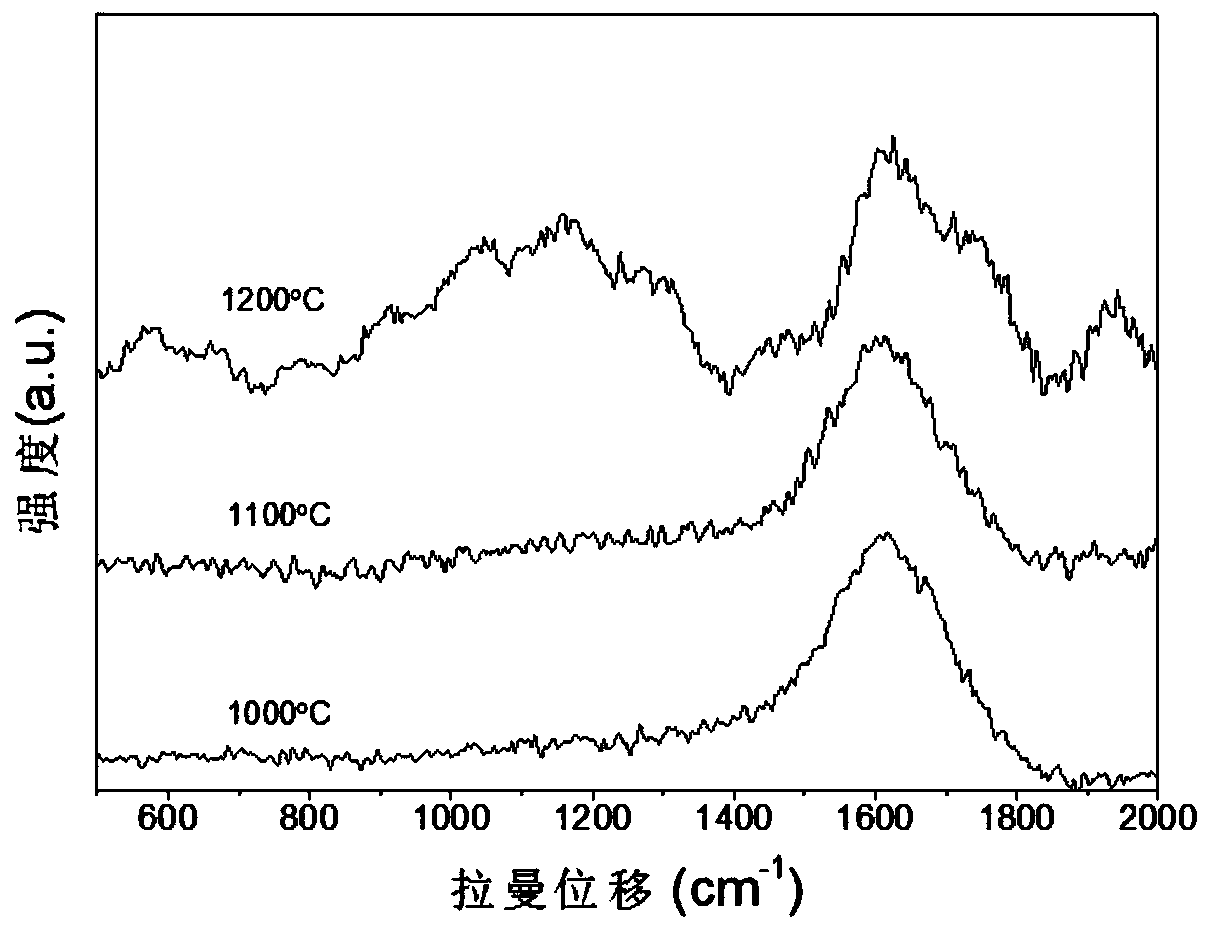

[0041] Utilize X-ray diffractometer (Bruker D8, Germany) to obtain block and analyze, as figure 2 As shown, it can be seen that its phase composition is amorphous carbon; the obtained block was analyzed by Raman spectrometer (HORIBA Jobin Yvon), as shown in image 3 As shown, it can be seen that it is characterized by amorphous carbon, and there are sp 3 The infl...

Embodiment 2

[0043] High-purity C produced by Alfa Aisha Chemical Co., Ltd. 60 The fullerene powder is prefabricated into a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, which is put into a hexagonal boron nitride crucible, and then loaded into a standard 8 / 3 high-temperature and high-pressure assembly block, and the assembly block is loaded into a T25 ultra- The high-pressure temperature synthesis device is heated for 120 minutes at a pressure of 25 GPa and a temperature of 1100 ° C. The synthesized amorphous carbon block is as follows figure 1 as shown in b.

[0044] Utilize X-ray diffractometer (Bruker D8, Germany) to obtain block and analyze, as figure 2 As shown, it can be seen that its phase composition is amorphous carbon; the obtained block was analyzed by Raman spectrometer (HORIBA Jobin Yvon), as shown in image 3 As shown, it can be seen that it is the characteristic of amorphous carbon; the analysis results of high-resolution electron microscope and elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com