Superhard semiconducting amorphous carbon bulk material and preparation method thereof

A technology of bulk materials and semiconductors, applied in the application of ultra-high pressure processes, etc., can solve the problems of insufficient density and hardness, thin film thickness, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the present invention is as follows:

[0023] (1) High-purity C 60 The fullerene powder is prefabricated into a cylindrical body with a diameter of 1.2 or 2 mm and a height of 2.3 mm;

[0024] (2) Put the obtained cylindrical body into a hexagonal boron nitride crucible, and then put it into a standard 8 / 3 high temperature and high pressure assembly block or a standard 10 / 5 high temperature and high pressure assembly block;

[0025] (3) Place the assembly block in a T25 ultra-high pressure thermosynthesis device for high temperature and high pressure treatment, the temperature of the high temperature and high pressure treatment is 500-2000°C, the pressure is 8-25GPa, and the holding time is 10-120 minutes;

[0026] (4) After the treatment is completed, a superhard semiconductor amorphous carbon bulk material with a diameter of 1-1.9mm and a height of 1.2-1.7mm is obtained.

[0027] Compared with the prior art, the present invention has the fo...

Embodiment 1

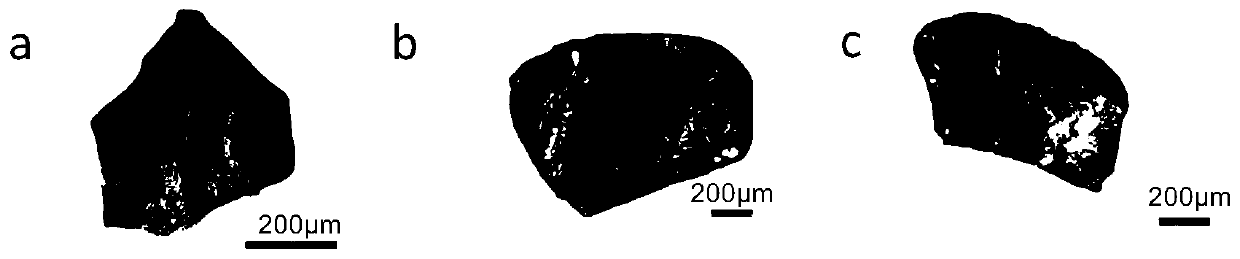

[0032] High-purity C produced by Alfa Aisha Chemical Co., Ltd. 60 The fullerene powder is prefabricated into a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, which is put into a hexagonal boron nitride crucible, and then loaded into a standard 8 / 3 high-temperature and high-pressure assembly block, and the assembly block is loaded into a T25 ultra- The high-pressure temperature synthesis device is heated for 120 minutes at a pressure of 25 GPa and a temperature of 1200 ° C. The synthesized transparent amorphous carbon block is as follows figure 1 As shown in a, its density is 3.4±0.1(g / cm 3 ).

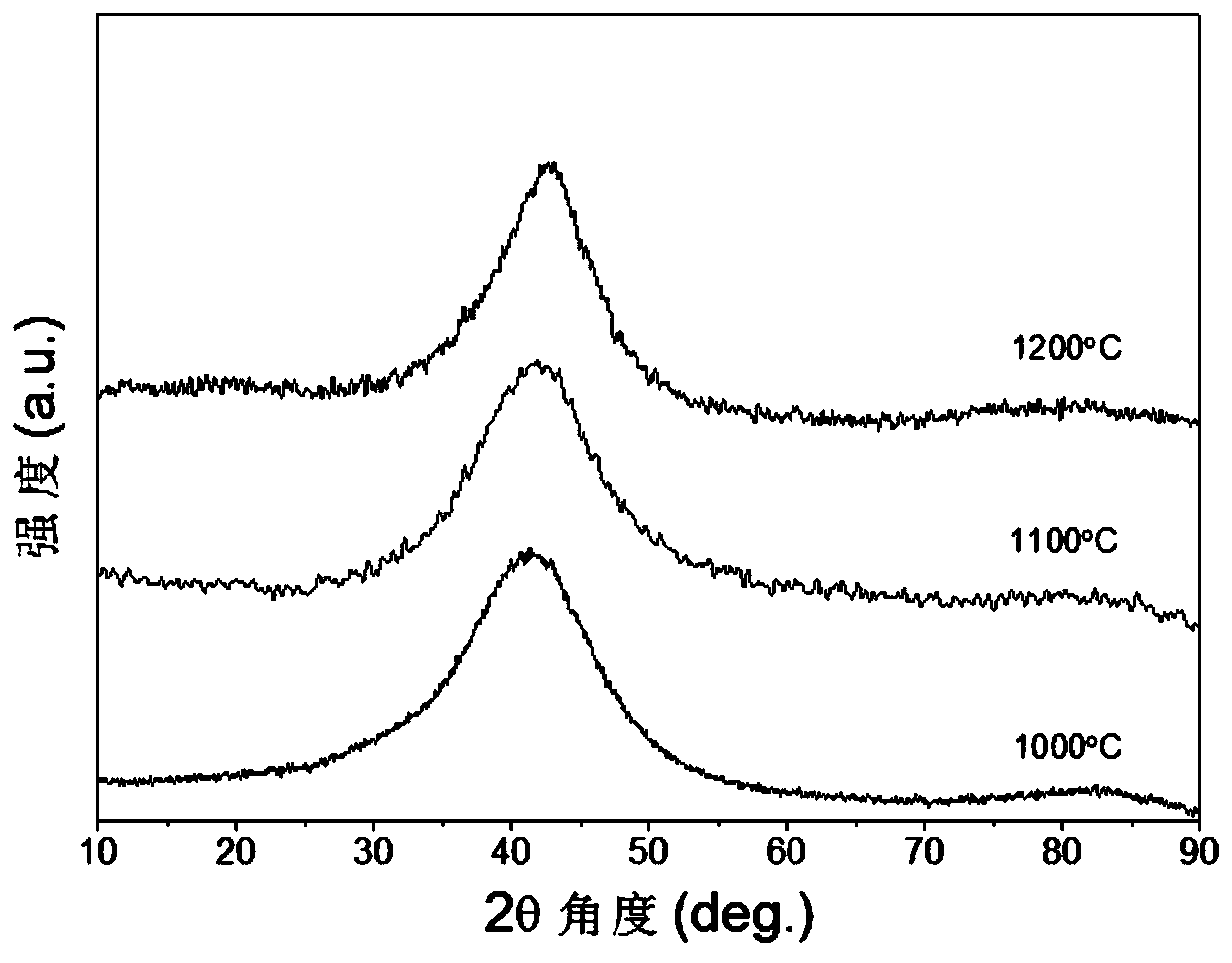

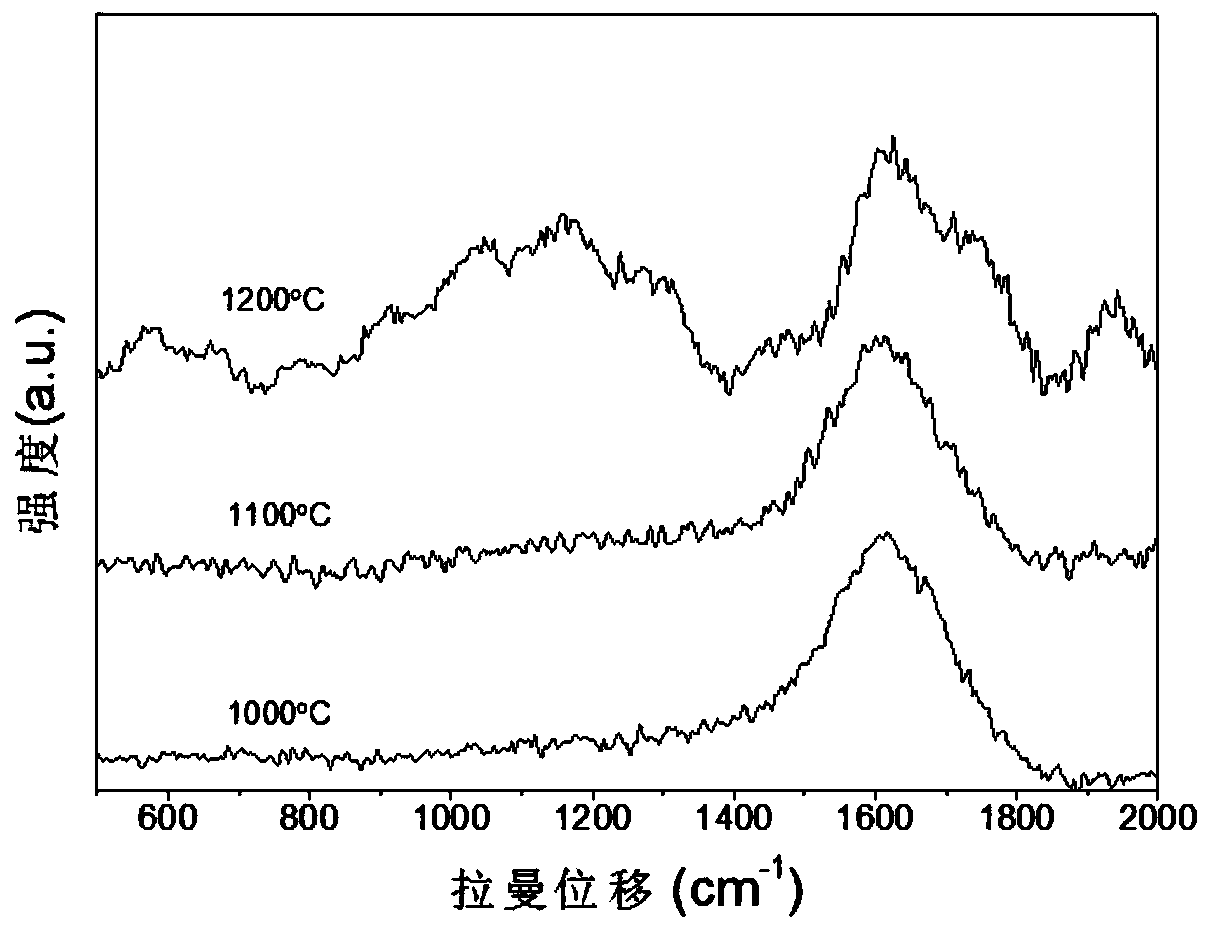

[0033] Utilize X-ray diffractometer (Bruker D8, Germany) to obtain block and analyze, as figure 2 As shown, it can be seen that its phase composition is amorphous carbon; the obtained block is analyzed by a Raman spectrometer (HORIBA Jobin Yvon), as shown in image 3 As shown, it can be seen that it is characterized by amorphous carbon, and there is sp 3 The influ...

Embodiment 2

[0035] High-purity C produced by Alfa Aisha Chemical Co., Ltd. 60 The fullerene powder is prefabricated into a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, which is put into a hexagonal boron nitride crucible, and then loaded into a standard 8 / 3 high-temperature and high-pressure assembly block, and the assembly block is loaded into a T25 ultra- The high-pressure temperature synthesis device is heated for 120 minutes at a pressure of 25 GPa and a temperature of 1100 ° C. The synthesized amorphous carbon block is as follows figure 1 as shown in b.

[0036] Utilize X-ray diffractometer (Bruker D8, Germany) to obtain block and analyze, as figure 2 As shown, it can be seen that its phase composition is amorphous carbon; the obtained block is analyzed by a Raman spectrometer (HORIBA Jobin Yvon), as shown in image 3 As shown, it can be seen that it is the characteristic of amorphous carbon; the analysis results of high-resolution electron microscope and elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com