Method for separating cellulose, hemicellulose and lignin in cotton stalk

A technology of hemicellulose and separation method, which is applied in the direction of raw material separation, non-woody plant/crop pulp, pulp dehydration, etc., can solve the problems of long production cycle and unfavorable industrial production, and achieve high conversion rate, safe operation and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

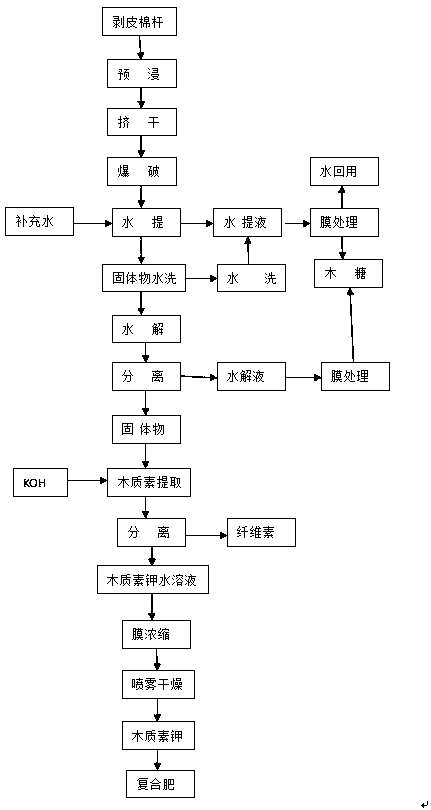

Image

Examples

Embodiment 1

[0029] The method for separating and fully utilizing cellulose, hemicellulose and lignin in cotton stalks comprises the following steps:

[0030] (1) Pretreatment: After the collected cotton stalks are separated, they are cut into lengths of 8-12cm. After screening, they enter a continuous presoaker for presoaking with an aqueous solution containing dilute sulfuric acid with a mass concentration of 0.4%. The ratio is 1:6. The presoaking temperature is normal temperature and the time is 6h.

[0031] (2) Squeeze dry: dehydrate the material after soaking in the continuous prepreg machine to make the water content 40%;

[0032] (3) Steam explosion treatment: Put the dehydrated cotton stalks into the steam explosion device for steam explosion treatment; when steam explosion treatment, first pressurize with steam to 2.0MPa, then pressurize with compressed air to 3.5MPa, and keep for 120s , to achieve instant explosion.

[0033] (4) Water washing to extract xylose: extract xylose ...

Embodiment 2

[0040] The method for separating and fully utilizing cellulose, hemicellulose and lignin in cotton stalks comprises the following steps:

[0041] (1) Pretreatment: After the collected cotton stalks are separated, they are cut into lengths of 8-12cm. After screening, they are put into a continuous presoaker and presoaked with an aqueous solution containing 0.4%% dilute sulfuric acid. The solid-to-liquid ratio is 1: 6.

[0042] (2) Squeeze dry: dehydrate the material after soaking in the continuous prepreg machine to make the water content 40%;

[0043] (3) Steam explosion treatment: Put the dehydrated cotton stalks into the steam explosion device for steam explosion treatment; when steam explosion treatment, first pressurize with steam to 2.0MPa, then pressurize with compressed air to 3.5MPa, and keep for 120s , burst instantly.

[0044] (4) Water washing to extract xylose: extract xylose from the material after gas explosion, the mass ratio of material to water is 1:10, the ...

Embodiment 3

[0051] The method for separating and fully utilizing cellulose, hemicellulose and lignin in cotton stalks comprises the following steps:

[0052] (1) Pretreatment: After the collected cotton stalks are separated, they are cut into lengths of 8-12cm. After screening, they are put into a continuous presoaker and presoaked with an aqueous solution containing 0.4%% dilute sulfuric acid. The solid-to-liquid ratio is 1: 6.

[0053] (2) Squeeze dry: dehydrate the material after soaking in the continuous prepreg machine to make the water content 40%;

[0054] (3) Steam explosion treatment: Put the dehydrated cotton stalks into the steam explosion device for steam explosion treatment; during steam explosion treatment, first pressurize to 2.0MPa with steam, then pressurize to 5MPa with compressed air, and keep it for 120s. It exploded instantly.

[0055] (4) Water washing to extract xylose: extract xylose from the material after gas explosion, the mass ratio of material to water is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com