Silicon crystal orientation discriminator

A discriminator and silicon crystal technology, which is applied in the field of optics, can solve the problems of limited positioning accuracy of the notch in the wafer crystal direction, cannot meet the processing requirements of micro devices, and the quality of processed products is not high, and achieve simple structure, high reliability, and fast response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

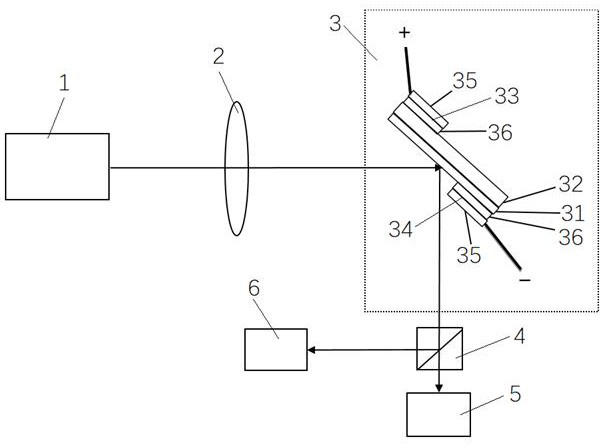

[0012] Example figure 1 As shown, the silicon crystal orientation discriminator of the present invention includes a laser emitter 1, a lens 2, a detection unit 3, a beam splitting unit 4, a light intensity detector 5, and a polarization detector 6 arranged sequentially along the beam direction, and the laser emitter 1. The emitted laser light is focused by the lens 2 and irradiated to the detection unit 3. The detection unit 3 forms reflected light and outputs it to the beam splitting unit 4. The beam splitting unit 4 outputs two beams and is respectively detected by the light intensity. Receiver 5 and polarization detector 6, the light intensity detector 5 measures the light intensity and spot displacement of the reflected laser light after the detection unit 3, and the polarization detector 6 measures the polarization of the reflected laser light after the inspection unit 3 and spot displacement.

[0013] Preferably, the detection unit 3 includes a silicon plate 32 coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com