Wave absorbing agent and preparation method thereof

A wave-absorbing agent and solvent technology, which is applied in the field of wave-absorbing materials, can solve problems such as cumbersome process steps, poor wave-absorbing performance, and poor wave-absorbing performance, and achieve simple process, significant low-frequency effect, and good low-frequency wave-absorbing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

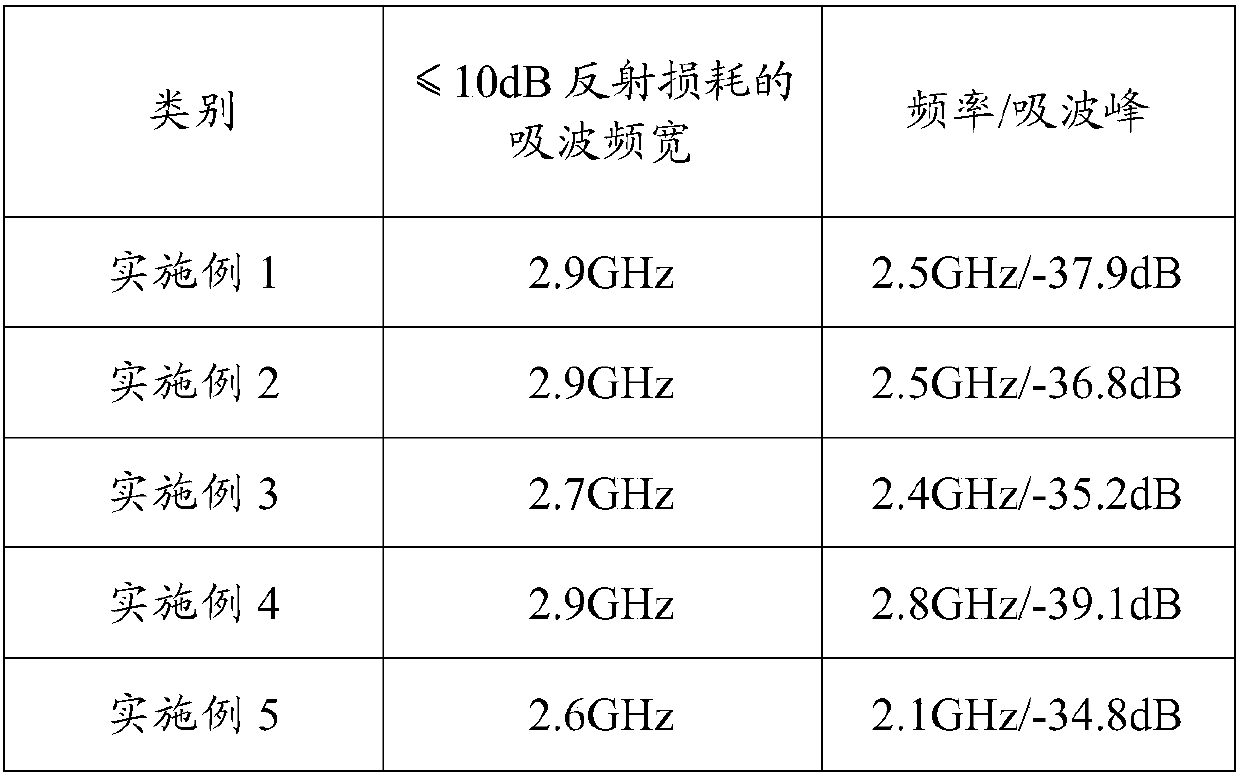

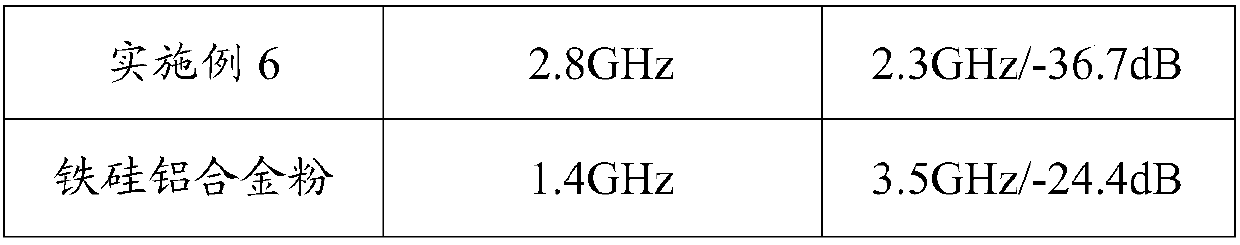

Examples

preparation example Construction

[0026] The invention provides a wave absorbing agent and a preparation method thereof, the method comprising the following steps:

[0027] Add 100-300 parts of sendust particles to 300-400 parts of absolute ethanol, stir evenly and put them into a horizontal planetary ball mill for ball milling (that is, wet milling in a ball mill tank), the speed of ball milling is 300-450r / min, and the time of ball milling is 12-18h; wherein, the mass ratio of agate beads used in ball milling to sendust particles is 8-15:0.5-1.5, and agate beads are made of diameters of 10mm, 6mm, 3mm large, medium and small agate beads, the mass ratio of large, medium and small agate beads is 2-5:25-40:50-70. After the ball milling is completed, the slurry is taken out and dried at 40-80° C. for 5-8 hours to obtain a ball-milled powder of sendust with a thickness of about 0.5-1.5 μm.

[0028] Mix 20-50 parts of coupling agent and 4-10 parts of calcium stearate evenly, then add to absolute ethanol, isopropa...

Embodiment 1

[0031] Add 100 parts of sendust particles to 300 parts of absolute ethanol, stir evenly and put it into a horizontal planetary ball mill for ball milling (that is, wet milling in a ball milling tank), the speed of ball milling is 400r / min , the time of ball milling is 15h; Wherein, the mass ratio of the agate beads used in the ball milling and sendust particles is 8:1, agate beads are made up of three kinds of agate beads with diameters of 10mm, 6mm, 3mm, large, medium and small, The mass ratio of large, medium and small agate beads is 3:35:60. After the ball milling is completed, the slurry is taken out, heated and dried at 60° C. for 7 hours, and a ball milled powder of sendust with a thickness of about 1 μm is obtained.

[0032] Mix 30 parts of coupling agent KH550 and 7 parts of calcium stearate evenly, then add them into absolute ethanol solution, and then adjust the pH value to 4-6 by adding acetic acid to form a mixed solution; then mix 50 parts of iron silicon Add alu...

Embodiment 2

[0034] Add 220 parts of sendust particles to 350 parts of absolute ethanol, stir evenly and put it into a horizontal planetary ball mill for ball milling (that is, wet milling in a ball mill tank), the speed of ball milling is 350r / min , the time of ball milling is 15h; Wherein, the mass ratio of the agate beads used in the ball milling and sendust particles is 10:1, and the agate beads are composed of three kinds of agate beads with diameters of 10mm, 6mm and 3mm, large, medium and small, The mass ratio of large, medium and small agate beads is 3:25:50. After the ball milling is completed, the slurry is taken out and dried at 70° C. for 6 hours to obtain a ball milling powder of sendust with a thickness of about 0.8 μm.

[0035] Mix 45 parts of coupling agent A-1120 and 8 parts of calcium stearate evenly, then add it to the isopropanol solution, and then adjust the pH value to 4-6 by adding dilute hydrochloric acid with a mass fraction lower than 20%, Form a mixed solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com