Production method of maotai-flavor hard liquor made with yeast

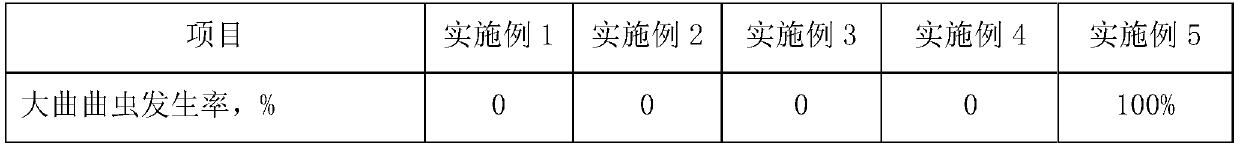

A production method, the sauce-flavored technology, is applied in the production field of the sauce-flavored Daqu, which can solve the problems of Daqu worms and other problems, and achieve the effect of thick body, avoiding internal worms, and increasing the color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of production method of sauce-flavored Daqu of the present invention comprises the following steps:

[0039] (A) Raw material processing: After the fermentation of solid-state vinegar, add a water jacket to pour the total acid content in the vinegar dregs to less than 0.2g / 100g, and squeeze the vinegar dregs to a water content of 55% through an extruder; after 6 months of high-salt dilute soy sauce fermentation , the crude oil is squeezed out through a press, and the remaining soy sauce residue has a moisture content of 45%, which is pulverized by a pulverizer and passed through a 80-mesh sieve to obtain sauce residue; wheat moistening water is 40%, pulverized by a pulverizer, and passed through a 40-mesh sieve to obtain wheat flour.

[0040] (B) Mixed inoculation buckling: by weight ratio vinegar residue: sauce residue: wheat flour = 1:1:4, mix evenly, add 1% high temperature resistant bacterial enzyme, 2% Aspergillus niger, stir evenly and pass through the bendi...

Embodiment 2

[0045] A kind of production method of sauce-flavored Daqu of the present invention comprises the following steps:

[0046] (A) Raw material processing: After the fermentation of solid vinegar, add a water jacket to pour the total acid content in the vinegar dregs to less than 0.2g / 100g, and squeeze the vinegar dregs through an extruder until the water content reaches 60%; after 6 months of high-salt dilute soy sauce fermentation , the crude oil is squeezed out through a press, and the remaining soy sauce residue has a moisture content of 40%, which is pulverized by a pulverizer through a 80-mesh sieve to obtain sauce residue; 35% of wheat moistened water is pulverized by a pulverizer, and passed through a 40-mesh sieve to obtain wheat flour.

[0047] (B) Mixed inoculation buckling: by weight ratio vinegar residue: sauce residue: wheat flour = 1:1:2, mix evenly, add 2% high temperature resistant bacterial enzyme, 1% Aspergillus niger, stir evenly and pass through the roller pres...

Embodiment 3

[0052] A kind of production method of sauce-flavored Daqu of the present invention comprises the following steps:

[0053] (A) Raw material processing: After the fermentation of solid vinegar, add a water jacket to pour the total acid content in the vinegar dregs to less than 0.2g / 100g, and squeeze the vinegar dregs through an extruder until the water content reaches 60%; after 6 months of high-salt dilute soy sauce fermentation , the crude oil is squeezed out through a press, and the remaining soy sauce residue has a moisture content of 40%, which is pulverized by a pulverizer through a 80-mesh sieve to obtain sauce residue; 35% of wheat moistened water is pulverized by a pulverizer, and passed through a 40-mesh sieve to obtain wheat flour.

[0054] (B) Mixed inoculation buckling: Mix vinegar residue: sauce residue: wheat flour 1:1:3 by weight evenly, add 2% high temperature resistant bacterial enzyme, 1% Aspergillus niger, stir evenly and pass through the koji machine to buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com