Preparation method of structured lipid of saturated fatty acid and medium-long chain fatty acid

A medium and long-chain fatty acid, structured lipid technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of increasing blood lipids, cardiovascular blockage, affecting calcium absorption, and reducing intestinal fat absorption rate, etc. Achieving the effect of wide application range, improved absorption rate and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

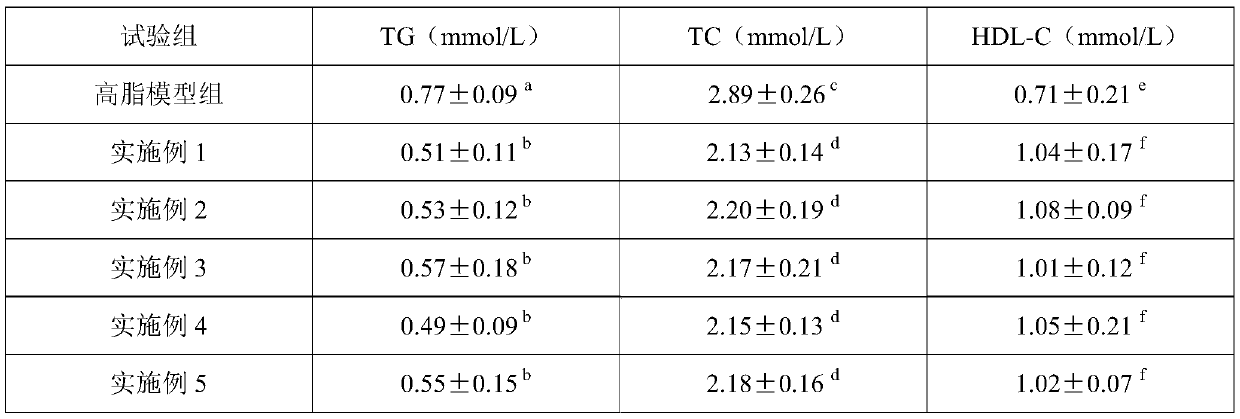

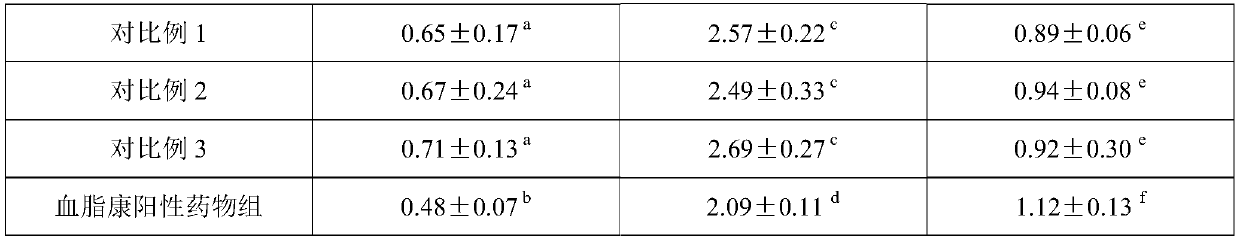

Examples

Embodiment 1

[0042] (1) Put 16 parts of purified caprylic triglyceride and 16 parts of purified rapeseed oil into a closed container (with lipase collection device) reactor, and carry out transesterification at a temperature of 50°C After reaction and treatment, medium and long chain fatty acids are obtained.

[0043] (2) Put 6 parts of saturated fatty acid palmitic acid (raw coconut oil) and 6 parts of the above-mentioned medium and long-chain fatty acid triglycerides into the reverse ultrasonic enzyme reactor, add 0.2% sodium ethylate at 45 ° C under normal pressure, and react After 40 minutes, 0.4% 435 lipase was added, and transesterification was carried out for 4 hours at 60° C. and a vacuum of 300 Pa to obtain material 1;

[0044] (3) To the material 1, add 50% by weight of 99% food-grade ethanol with a concentration of 99% to mix and inactivate the enzyme activity, cool down, winterize to -5°C, transport to an ultrasonic filter for filtration, and then add 3 ‰ of ascorbyl palmitate...

Embodiment 2

[0046] (1) Put 15 parts of the purified caprylic triglyceride and 15 parts of the purified Xanthania sorbifolium oil into a closed container (with a lipase collection device) reactor, and carry out transesterification at a temperature of 40°C After reaction and treatment, medium and long chain fatty acids are obtained.

[0047] (2) Put 1 part of saturated fatty acid coconut oil and 1 part of the above-mentioned medium and long-chain fatty acid triglycerides into the reverse ultrasonic enzyme reactor, add 0.1% sodium ethylate, and react for 1 hour under normal pressure at 40 °C before adding 0.1% TL lipase, under the condition of 40°C and vacuum degree of 200pa, carry out transesterification reaction for 6h to obtain material 1;

[0048] (3) In the material 1, add 35% by weight of 95% food-grade ethanol with a concentration of 95% to mix and inactivate the enzyme activity, cool down, winterize to -2°C, and transport it to an ultrasonic filter for filtration, then add 1 ‰ of as...

Embodiment 3

[0050] (1) Put 75 parts of caprylic triglycerides after purification, 30 parts of linseed oil after purification, and 35 parts of borage oil into a closed container (with lipase collection device) reactor, at a temperature of 50°C Next, transesterification is carried out, and after treatment, medium and long-chain fatty acids are obtained.

[0051] (2) Put 11 parts of saturated fatty acid myristic acid (raw material butter) and 9 parts of the above-mentioned medium and long-chain fatty acid triglycerides into a closed container stirring reactor, add 0.5% sodium ethylate and react at 35°C under normal pressure conditions After 30 minutes, 0.5% 435 lipase was added, and the transesterification reaction was carried out for 2 hours at 85°C and a vacuum of 500pa to obtain material 1;

[0052] (3) In the material 1, add 60% by weight of 99.5% food-grade ethanol with a concentration of 99.5% to mix the passivation enzyme activity, cool down, winterize to -10°C, and transport it to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com