Tribenuron-methyl oil suspension agent and preparation method thereof

A technology for trisulfuron-methyl oil and suspending agent is applied in the field of herbicides to achieve the effects of enhancing penetration, being beneficial to plant absorption, and reducing the cost of medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

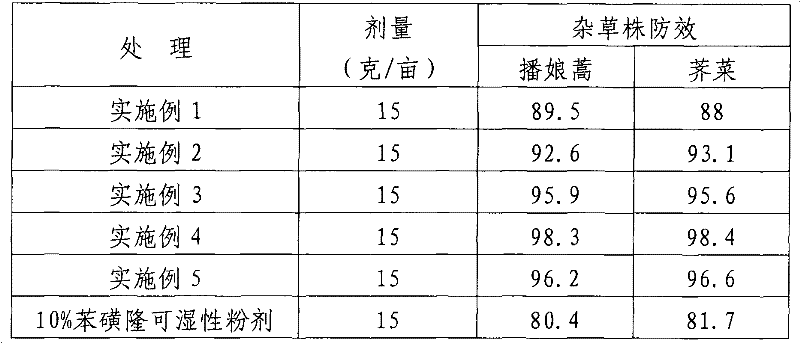

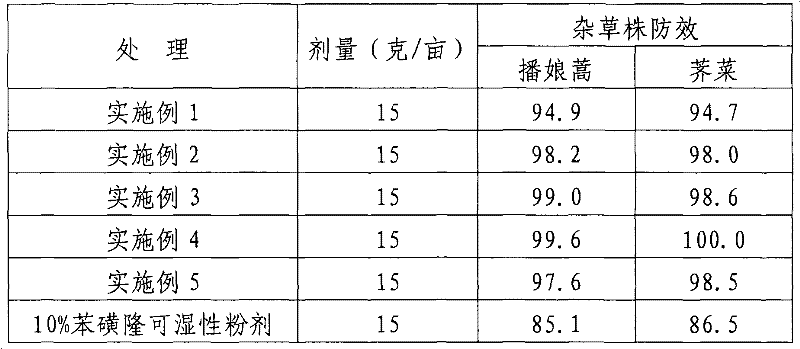

Examples

Embodiment 1

[0039] (1) Raw material ratio: Trisulfuron-methyl technical 5kg, phenethylphenol polyoxyethylene ether 10kg, nonylphenol polyoxyethylene ether phosphate 10kg, JFC 3kg, white carbon black 2kg, xanthan gum 0.02kg, ethyl alcohol Glycol 5kg, silicone defoamer 0.1kg, salad oil 64.88kg.

[0040] (2) Preparation process: add all 10kg of phenylethylphenol polyoxyethylene ether, 10kg of nonylphenol polyoxyethylene ether phosphate, 3kg of JFC, 5kg of ethylene glycol, 0.1kg of silicone defoamer, salad Oil 64.88kg, high-shear stirring for 30 minutes until the materials are evenly mixed. Then add 5 kg of tribenuron-methyl, 2 kg of white carbon black, and 0.02 kg of xanthan gum under stirring, and stir for 1 hour. Afterwards, the material is sanded in a sand mill to make the material diameter meet the specified requirements (generally, the average particle diameter is below 3 microns). Finally, the material is transferred to the reactor, and various indicators are tested according to the ...

Embodiment 2

[0042] (1) Raw material ratio: Trisulfuron-methyl technical 10kg, phenethylphenol polyoxyethylene ether 10kg, nonylphenol polyoxyethylene ether phosphate 15kg, JFC 3kg, white carbon black 1kg, xanthan gum 0.02kg, ethylene glycol Alcohol 3kg, silicone defoamer 0.1kg, salad oil 57.88kg.

[0043] (2) Preparation process: add all 10kg of phenylethylphenol polyoxyethylene ether, 15kg of nonylphenol polyoxyethylene ether phosphate, 3kg of JFC, 3kg of ethylene glycol, 0.1kg of organic silicon defoamer, salad Oil 57.88kg, high-shear stirring for 30 minutes until the material is evenly mixed. Then add 10 kg of tribenuron-methyl, 1 kg of white carbon black, and 0.02 kg of xanthan gum under stirring state, and stir for 1 hour. Afterwards, the material is sanded in a sand mill to make the material diameter meet the specified requirements (generally, the average particle diameter is below 3 microns). Finally, the material is transferred to the reactor, and various indicators are tested a...

Embodiment 3

[0045] (1) Raw material ratio: 15kg of trisulfuron-methyl, 12kg of alkyl aryl polyoxyethylene polyoxypropylene ether, 23kg of nonylphenol polyoxyethylene ether phosphate, 6kg of fast penetrating agent, 0.5kg of magnesium aluminum silicate, Glycerin 3.5kg, silicone defoamer 0.15kg, salad oil 39.85kg.

[0046] (2) Preparation process: Add 12kg of all alkylaryl polyoxyethylene polyoxypropylene ethers, 23kg of nonylphenol polyoxyethylene ether phosphates, 6kg of fast penetrating agent T6kg, 3.5kg of glycerin, and silicone defoamer into the mixing kettle 0.15kg, salad oil 39.85kg, high-shear stirring for 30 minutes until the materials are evenly mixed. Then add 15kg of trisulfuron-methyl, 0.5kg of magnesium aluminum silicate, and stir for 1 hour. Afterwards, grind the material in a sand mill to make the material diameter meet the specified requirements (generally, the average particle size is below 3 microns) . Finally, the material is transferred to the reactor, and various indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com