Preparation method of saturated fatty acid and medium-long chain fatty acid structured lipid

A technology of medium and long-chain fatty acids and structural lipids, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of blood lipid elevation, cardiovascular blockage, affecting calcium absorption, constipation and flatulence, etc. Effect of improving absorption rate and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

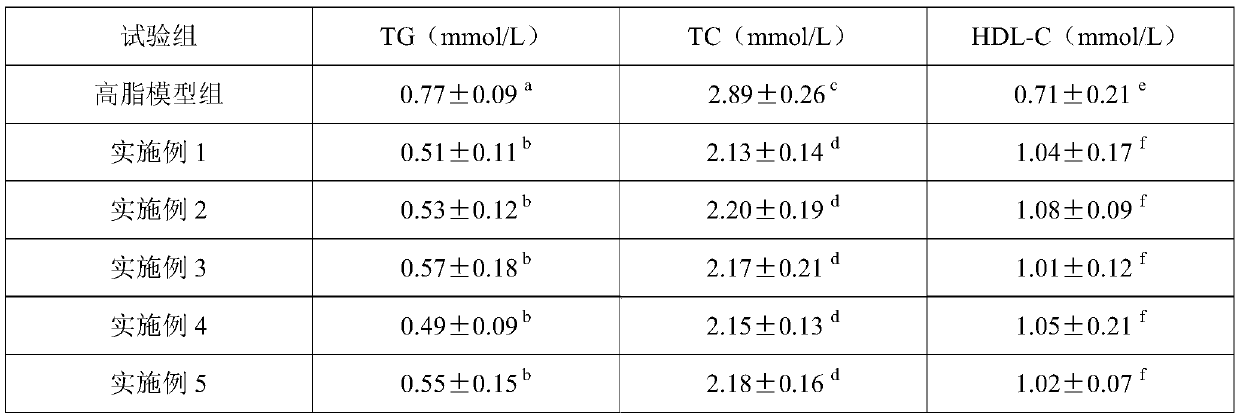

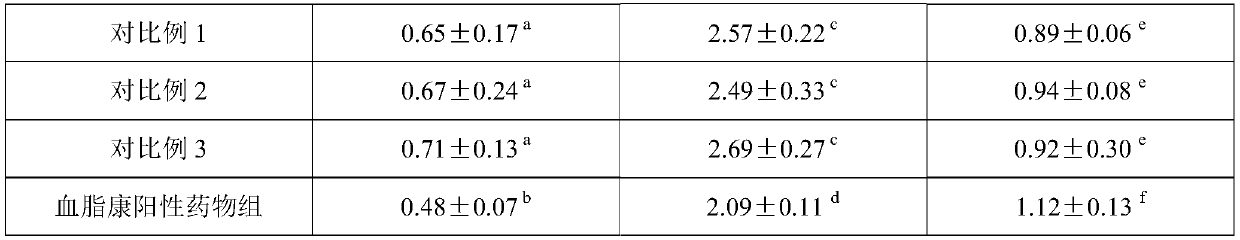

Examples

Embodiment 1

[0042] (1) Put 16 parts of purified caprylic triglyceride and 16 parts of purified rapeseed oil into a closed container (with lipase collection device) reactor, and carry out transesterification at a temperature of 50°C After reaction and treatment, medium and long chain fatty acids are obtained.

[0043] (2) Put 6 parts of saturated fatty acid palmitic acid (raw coconut oil) and 6 parts of the above-mentioned medium and long-chain fatty acid triglycerides into the reverse ultrasonic enzyme reactor, add 0.2% sodium ethylate at 45 ° C under normal pressure, and react After 40 minutes, 0.4% 435 lipase was added, and transesterification was carried out for 4 hours at 60° C. and a vacuum of 300 Pa to obtain material 1;

[0044] (3) To the material 1, add 50% by weight of 99% food-grade ethanol with a concentration of 99% to mix and inactivate the enzyme activity, cool down, winterize to -5°C, transport to an ultrasonic filter for filtration, and then add 3 ‰ of ascorbyl palmitate...

Embodiment 2

[0046] (1) Put 15 parts of the purified caprylic triglyceride and 15 parts of the purified Xanthania sorbifolium oil into a closed container (with a lipase collection device) reactor, and carry out transesterification at a temperature of 40°C After reaction and treatment, medium and long chain fatty acids are obtained.

[0047] (2) Put 1 part of saturated fatty acid coconut oil and 1 part of the above-mentioned medium and long-chain fatty acid triglycerides into the reverse ultrasonic enzyme reactor, add 0.1% sodium ethylate, and react for 1 hour under normal pressure at 40 °C before adding 0.1% TL lipase, under the condition of 40°C and vacuum degree of 200pa, carry out transesterification reaction for 6h to obtain material 1;

[0048] (3) In the material 1, add 35% by weight of 95% food-grade ethanol with a concentration of 95% to mix and inactivate the enzyme activity, cool down, winterize to -2°C, and transport it to an ultrasonic filter for filtration, then add 1 ‰ of as...

Embodiment 3

[0050] (1) Put 75 parts of caprylic triglycerides after purification, 30 parts of linseed oil after purification, and 35 parts of borage oil into a closed container (with lipase collection device) reactor, at a temperature of 50°C Next, transesterification is carried out, and after treatment, medium and long-chain fatty acids are obtained.

[0051] (2) Put 11 parts of saturated fatty acid myristic acid (raw material butter) and 9 parts of the above-mentioned medium and long-chain fatty acid triglycerides into a closed container stirring reactor, add 0.5% sodium ethylate and react at 35°C under normal pressure conditions After 30 minutes, 0.5% 435 lipase was added, and the transesterification reaction was carried out for 2 hours at 85°C and a vacuum of 500pa to obtain material 1;

[0052] (3) In the material 1, add 60% by weight of 99.5% food-grade ethanol with a concentration of 99.5% to mix the passivation enzyme activity, cool down, winterize to -10°C, and transport it to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com