Preparation method of composite nanofiltration membrane and composite nanofiltration membrane prepared therefrom

A technology of composite nanofiltration membrane and membrane casting liquid, applied in the field of nanofiltration membrane, can solve the problems of complex preparation process, poor solvent resistance, low process requirements, etc., and achieve low process requirements, high flux and interception performance, and raw material cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] One aspect of the present invention relates to a preparation method of a composite nanofiltration membrane, and another aspect relates to a composite nanofiltration membrane.

[0047] 1, the preparation method of composite nanofiltration membrane of the present invention

[0048] As the preparation method of composite nanofiltration membrane of the present invention, specifically comprise the following steps:

[0049] (1) preparing an aliphatic polyamide solution as a casting solution, making the casting solution solidify and form a film on the reinforcing material;

[0050] (2) immersing the film obtained in step (1) in a heat treatment solution;

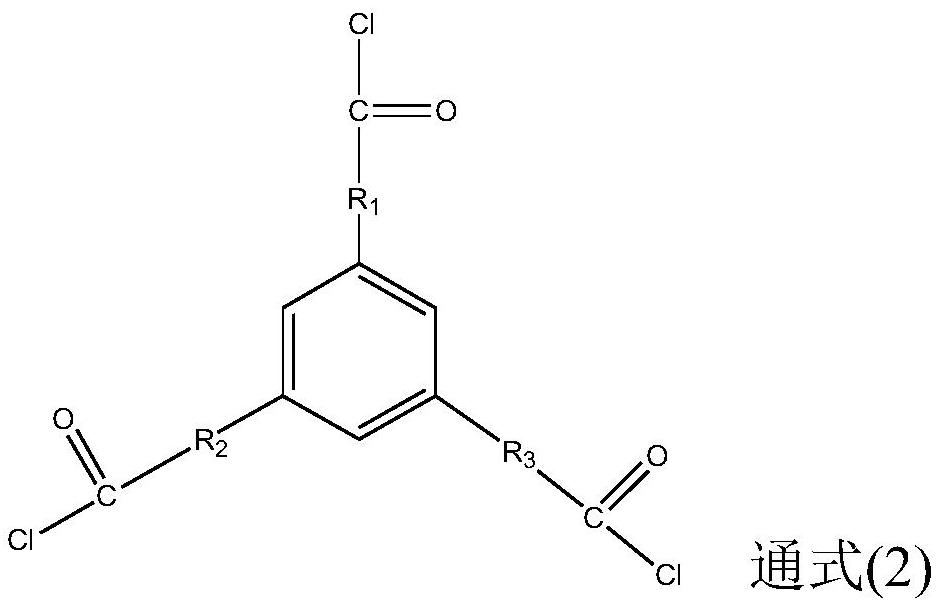

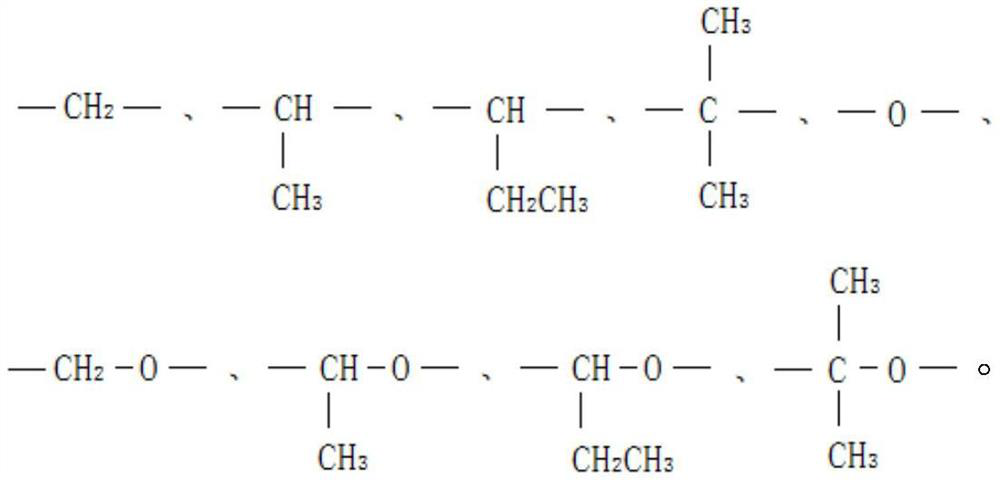

[0051] (3) immersing the film obtained in step (2) in an aqueous phase solution containing an amine compound, and then immersing the film in an organic phase solution containing an acid chloride compound;

[0052] (4) Obtain the composite nanofiltration membrane after post-treatment and drying.

[0053] Preferably, the al...

Embodiment 1

[0106] (1) Under nitrogen protection, add 10g of lithium chloride and 10g of calcium chloride to 144g of methanol, heat and stir at 55°C for 1 hour until dissolved; then add 36g of polyamide 6 particles to the above solution, at 55 After stirring at ℃ for 10 hours, the polyamide particles were completely dissolved to form a homogeneous aliphatic polyamide casting solution with a mass fraction of 18%; the homogeneous polyamide casting solution was evenly scraped on the surface of the PP non-woven fabric with a scraper machine , and then quickly immersed in 10wt.% methanol aqueous solution at 10°C, and solidified for 5 minutes;

[0107] (2) immerse the membrane in pure water at 80°C, and heat-treat it for 10 minutes to obtain a membrane with an aliphatic polyamide support layer;

[0108] (3) Dissolve 10g m-phenylenediamine, 10g p-phenylenediamine, 2g sodium dodecylbenzenesulfonate, and 2g sodium carbonate in 976g pure water, stir for 30 minutes until it dissolves completely, as ...

Embodiment 2

[0111] (1) Under nitrogen protection, add 10g of lithium chloride and 10g of calcium chloride to 144g of methanol, heat and stir at 55°C for 1 hour until dissolved; then add 36g of polyamide 6 particles to the above solution, at 55 After stirring at ℃ for 10 hours, the polyamide particles were completely dissolved to form a homogeneous aliphatic polyamide casting solution with a mass fraction of 18%; the homogeneous polyamide casting solution was evenly scraped on the surface of the PP non-woven fabric with a scraper machine , and then quickly immersed in 10wt.% methanol aqueous solution at 10°C, and solidified for 5 minutes;

[0112] (2) immerse the membrane in pure water at 80°C, and heat-treat it for 10 minutes to obtain a membrane with an aliphatic polyamide support layer;

[0113] (3) Dissolve 10g of m-phenylenediamine, 10g of piperazine, 2g of sodium dodecylbenzenesulfonate, and 2g of sodium carbonate in 976g of pure water, and stir for 30 minutes until it is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com