High-strength brazing method for molybdenum-copper alloy and stainless steel

A technology of molybdenum-copper alloy and brazing method, which is applied in the direction of welding medium, welding equipment, metal processing equipment, etc., can solve the problems of unfavorable promotion and application and many welding processes, and achieve the effects of easy promotion and application, simple process and reasonable matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

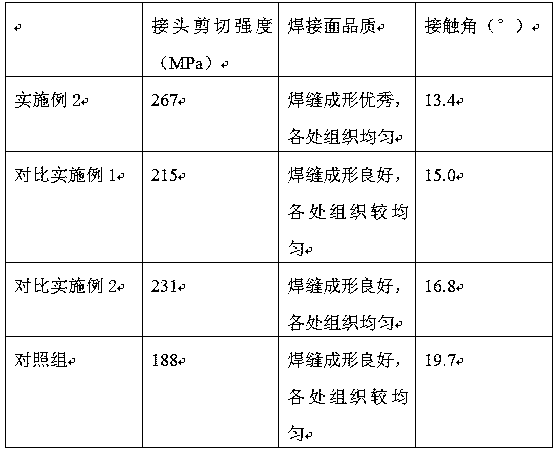

Examples

Embodiment 1

[0035] A high-strength brazing method for molybdenum-copper alloy and stainless steel, comprising the steps of:

[0036] (1) Surface cleaning treatment:

[0037] Put the molybdenum-copper alloy and stainless steel into the degreasing liquid for soaking and degreasing treatment, take it out after 10 minutes, then put it in the drying oven for drying treatment, take it out after 20 minutes, and finally polish it with sandpaper for later use;

[0038] (2) Surface modification treatment:

[0039] Put the molybdenum-copper alloy and stainless steel treated in step (1) into the ultraviolet irradiation box for irradiation treatment, and take them out after 30 minutes for later use;

[0040] (3) Brazing material preparation:

[0041] a. Immerse the attapulgite in the sulfuric acid solution for 4 minutes, take it out and then immerse it in the sodium hydroxide solution for 5 minutes, and finally take it out and rinse it with deionized water for later use;

[0042]b. Put the attapulg...

Embodiment 2

[0061] A high-strength brazing method for molybdenum-copper alloy and stainless steel, comprising the steps of:

[0062] (1) Surface cleaning treatment:

[0063] Put the molybdenum-copper alloy and stainless steel into the degreasing solution for soaking and degreasing treatment, take it out after 13 minutes, then put it in the drying oven for drying treatment, take it out after 22 minutes, and finally polish it with sandpaper for later use;

[0064] (2) Surface modification treatment:

[0065] Put the molybdenum-copper alloy and stainless steel treated in step (1) into the ultraviolet radiation box for irradiation treatment, and take them out after 35 minutes for later use;

[0066] (3) Brazing material preparation:

[0067] a. Immerse the attapulgite in the sulfuric acid solution for 5 minutes, take it out and then immerse it in the sodium hydroxide solution for 7 minutes, and finally take it out and rinse it with deionized water for later use;

[0068] b. Put the attapul...

Embodiment 3

[0087] A high-strength brazing method for molybdenum-copper alloy and stainless steel, comprising the steps of:

[0088] (1) Surface cleaning treatment:

[0089] Put the molybdenum-copper alloy and stainless steel into the degreasing solution for soaking and degreasing treatment, take it out after 15 minutes, then put it in the drying oven for drying treatment, take it out after 25 minutes, and finally polish it with sandpaper for later use;

[0090] (2) Surface modification treatment:

[0091] Put the molybdenum-copper alloy and stainless steel treated in step (1) into the ultraviolet radiation box for irradiation treatment, and take them out after 40 minutes for later use;

[0092] (3) Brazing material preparation:

[0093] a. Immerse the attapulgite in the sulfuric acid solution for 6 minutes, take it out and then immerse it in the sodium hydroxide solution for 8 minutes, and finally take it out and rinse it with deionized water for later use;

[0094] b. Put the attapul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com