Laser head containing moving atmosphere chamber and method for laser additive nonferrous metal

A technology of laser additive materials and non-ferrous metals, which is applied in the field of laser additive non-ferrous metals and laser heads, which can solve the problems of difficult to realize industrial applications, difficult to ensure the stability of the inert atmosphere in the additive area, and the limitation of processing space, so as to improve the accuracy of additive materials. Efficiency and quick response capability, shortened complex preparation process, strong flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

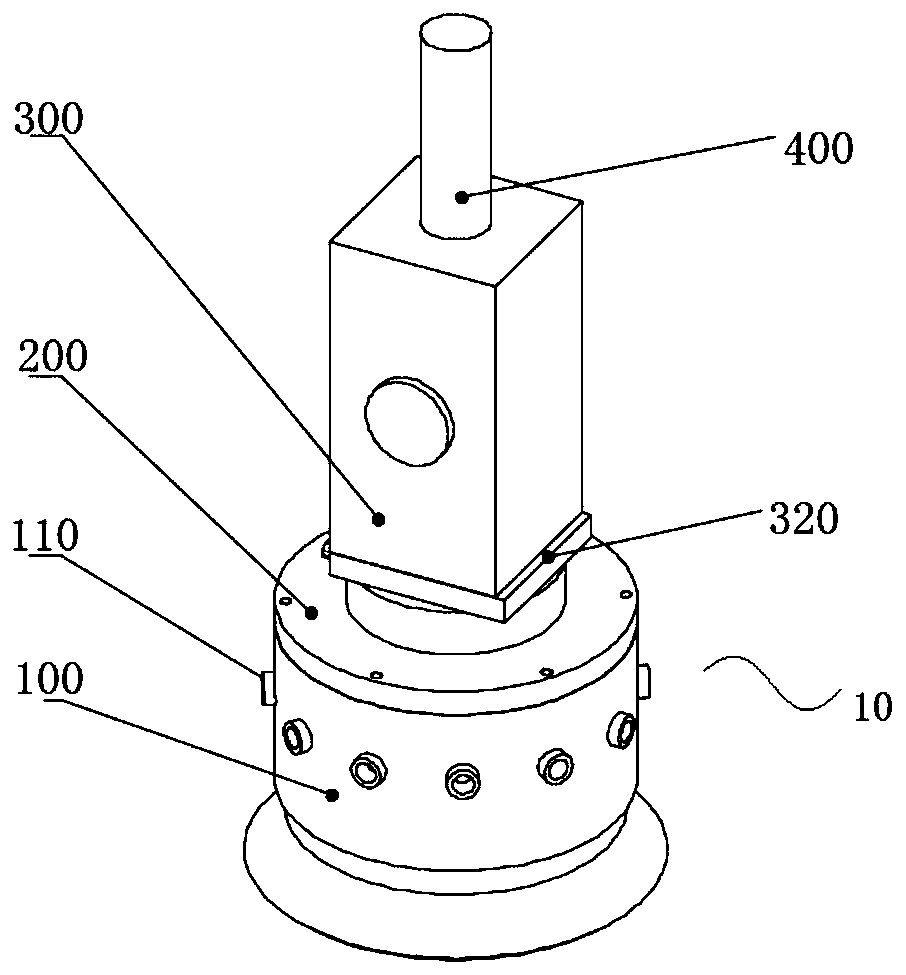

[0028] Example 1: as Figure 1-3 As shown, the laser head 10 with a moving atmosphere chamber according to the present invention includes a cylindrical protective cover 100, a connecting surface 200 at the top of the protective cover 100, and a laser head whose one end passes through the connecting surface 200 and is sealed and fixed to the protective cover 100. The main body 300 and the optical fiber transmission module 400 connected to the main body of the laser head.

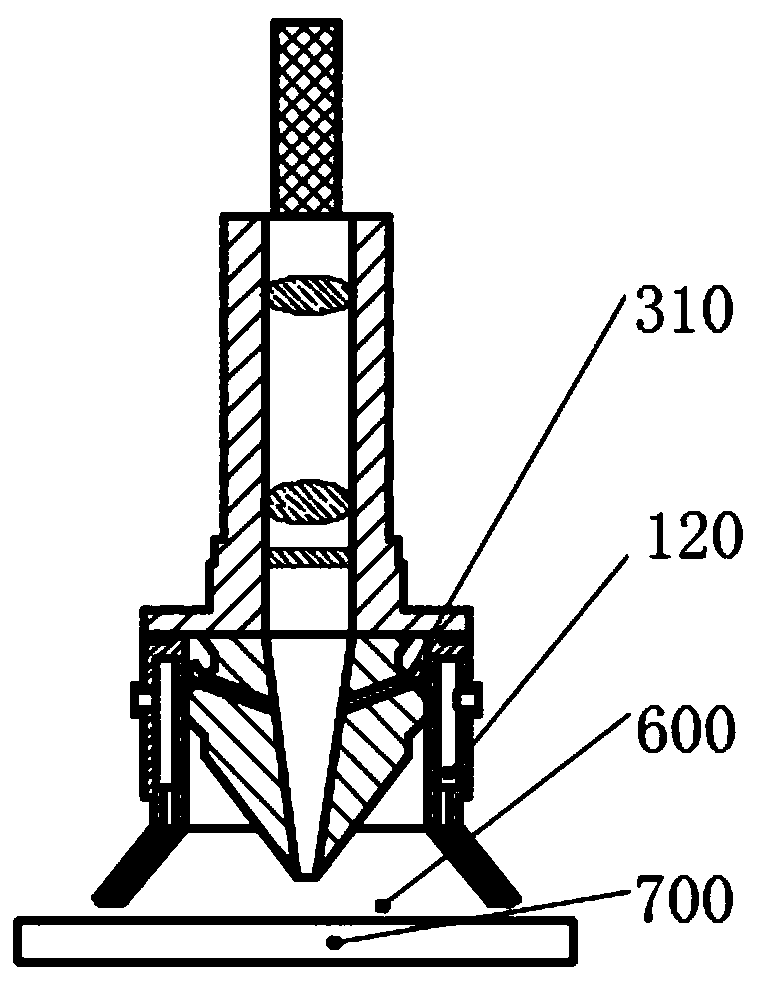

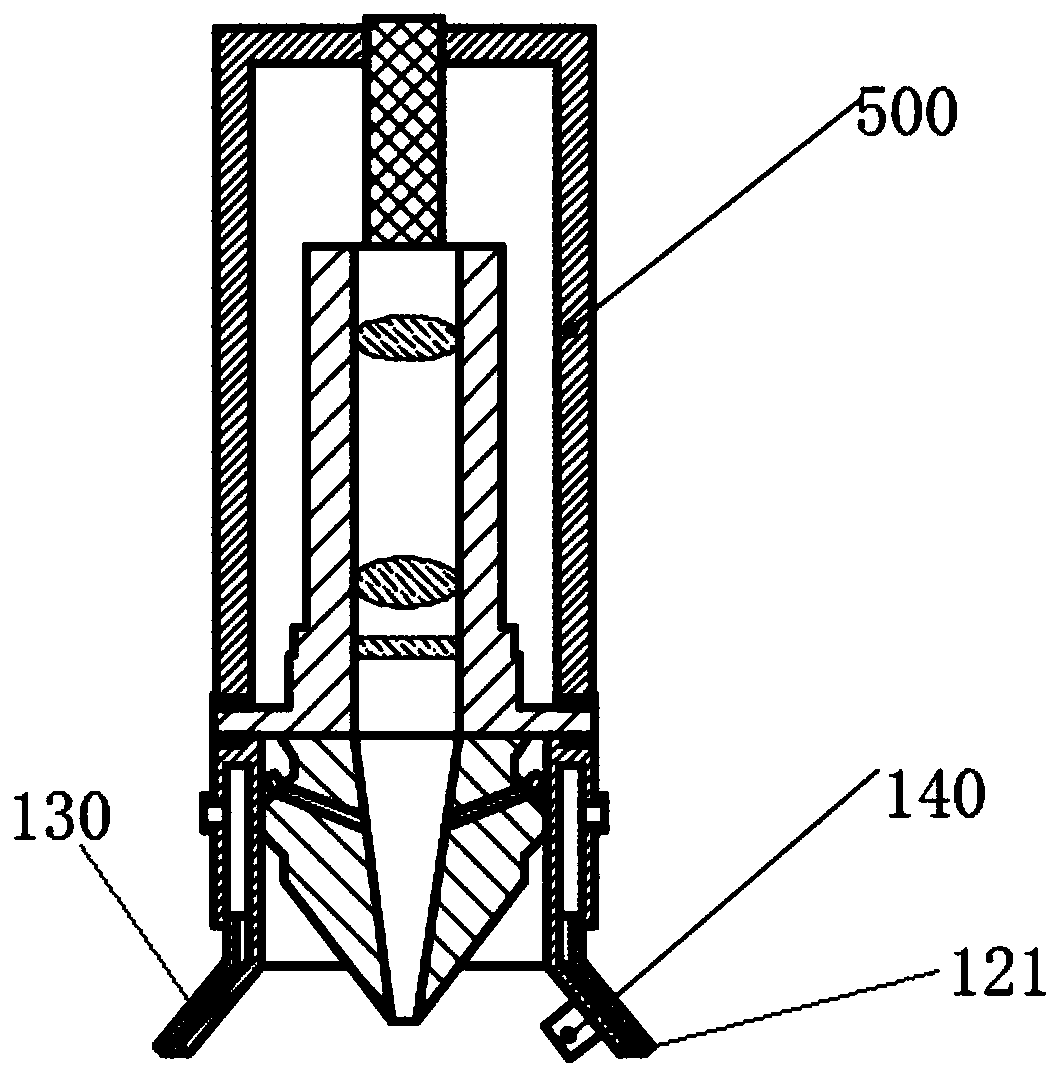

[0029]The bottom edge of the protective cover 100 expands outward to form a trumpet-shaped protective outer edge 130. The bottom edge of the protective outer edge is located on the same horizontal plane and is used for contacting the substrate 700. The upper end of the protective cover 100 is provided with an inertial opening on the outer wall surface of the protective cover. The gas inlet 110, the inert gas inlets are evenly distributed along the circumference of the outer wall of the protective cover, there...

Embodiment 2

[0033] Example 2: Laser additive non-ferrous metals in air using a laser head with a moving atmosphere chamber:

[0034] The first step: connect the laser head 10 containing the moving atmosphere chamber to the CNC machine tool equipment, and continuously introduce argon or helium with a purity of 99.999% as an inert gas through the inert gas inlet 110 set on the protective cover 100. The gas is sprayed from the outlet nozzle 121 through the second gas channel 120 to form an inert protective gas curtain, and at the same time, the inert gas is continuously introduced from the first gas channel 310 located on the main body 300 of the laser head, which can protect the molten pool from being oxidized and prevent the molten pool from being oxidized. The inert gas ejected from the head body and the inert gas ejected from the outlet nozzle together form an inert gas protective atmosphere 600 to establish a working environment for laser additive materials. Laser additive can be perfor...

Embodiment 3

[0038] Example 3: Underwater laser additive non-ferrous metals using a laser head with a moving atmosphere chamber:

[0039] Step 1: Add an outer cover 500 to the main body 300 of the laser head, fix the bottom end of the outer cover 500 to the connecting surface, connect the protective cover 100, the main body 300 of the laser head, and the outer cover 500 to the remote-controlled submersible, using the first step in Example 2 The method forms an inert gas protective atmosphere 600 .

[0040] Step 2: Put the above device into the designated water area, and the ROV adjusts the position through the push fans in different directions. Through the underwater camera system, the main body of the laser head 300 is vertically aligned with the area to be added. Before the ROV is launched, it is inert. The gas inlet 110 and the first gas channel 310 are continuously supplied with argon gas or helium gas, and gas is continuously supplied during the whole process of the additive process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com