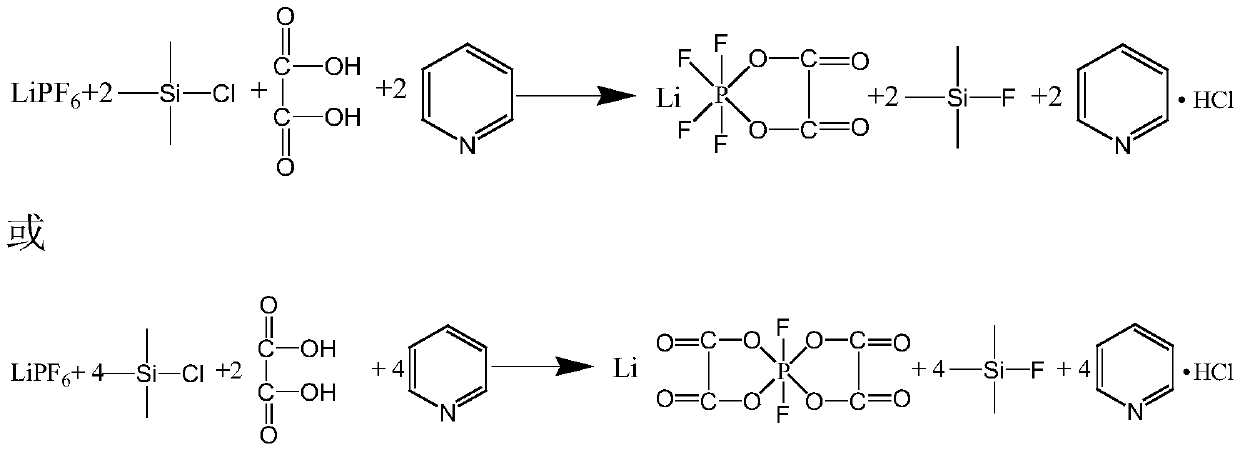

Preparation method of lithium tetrafluorooxalatophosphate and lithium difluorodioxalatophosphate

A technology of lithium difluorobisoxalate phosphate and lithium tetrafluorooxalate phosphate, which is applied in chemical instruments and methods, lithium compounds, alkali metal compounds, etc., can solve problems such as high energy consumption and safety risks, hidden safety hazards, and risks. Achieve the effect of reducing energy consumption, increasing productivity and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Bottom liquid configuration: under the protection of nitrogen, take 45.02g oxalic acid, 200g dimethyl carbonate and stir, take 79.1g pyridine dissolved in 100g dimethyl carbonate and stir evenly, slowly drop the pyridine solution into the oxalic acid solution, after the titration Stirring was continued for 30 min.

[0020] Configuration of titration solution: Under the protection of nitrogen, take 76g of lithium hexafluorophosphate and add it to 227.85g of dimethyl carbonate in batches, and stir while adding. After a uniform solution is formed, drop 108.64g of trimethylchlorosilane into the solution, and the titration is completed After forming a uniform solution, drop the titration solution into the bottom solution for the next step of reaction.

[0021] Set the temperature to -10°C. After the flask reaches the set temperature, slowly add the prepared titration solution into the bottom liquid. The dropping process takes 90 minutes. After the dropwise addition, continu...

Embodiment 2

[0024] Bottom liquid configuration: under the protection of nitrogen, take 99.07g oxalic acid, 200g dimethyl carbonate and stir, take 174.02g pyridine and dissolve it in 200g dimethyl carbonate, slowly drop the pyridine solution into the oxalic acid solution, after the titration Stirring was continued for 30 min.

[0025] Configuration of titration solution: Under the protection of nitrogen, take 76g of lithium hexafluorophosphate and add it to 227.85g of dimethyl carbonate in batches, and stir while adding. After a uniform solution is formed, drop 108.64g of trimethylchlorosilane into the solution, and the titration is completed After forming a uniform solution, drop the titration solution into the bottom solution for the next step of reaction.

[0026] Set the temperature to -10°C. After the flask reaches the set temperature, slowly add the prepared titration solution into the bottom liquid. The dropping process takes 90 minutes. After the dropwise addition, continue the he...

Embodiment 3

[0029] Bottom liquid configuration: Under nitrogen protection, take 99.04g oxalic acid, stir with 350g acetonitrile, take 74.91g imidazole and dissolve in 300g acetonitrile, slowly drop the imidazole solution into the oxalic acid solution, continue stirring for 30min after the titration is completed.

[0030] Configuration of titration solution: Under the protection of nitrogen, take 76g of lithium hexafluorophosphate and add it to 227.85g of acetonitrile in batches, and stir while adding. After a uniform solution is formed, 108.64g of trimethylchlorosilane is dropped into the solution. After the solution, the titration solution was dropped into the bottom solution to carry out the next step of reaction.

[0031] Set the temperature at 25°C. After the flask reaches the set temperature, slowly add the prepared titration solution into the bottom liquid, and the dropping process takes 60 minutes. As the reaction progresses, the bubbles in the solution gradually become more intens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com