Low-shrinkage corrosion-resistant ultrahigh-performance concrete, and preparation method, construction method and application thereof

An ultra-high-performance, corrosion-resistant technology, applied in the field of green ultra-high-performance building materials, can solve problems such as sulfate corrosion resistance, poor acid corrosion resistance, affecting the durability of architectural decoration components, affecting the appearance of architectural decoration components, etc., to achieve high anti-corrosion The effect of folding strength, ease of implementation, and small fluctuations in quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Furthermore, it is particularly prominent that the cement used in the present invention is high flexural super sulfate cement. The above-mentioned high flexural super sulfate cement refers to the high flexural super sulfate cement in the "high flexural super sulfate cement and its preparation method" disclosed by the publication number CN107827379A, which is the prior research achievement of the applicant . The high flexural super sulfate cement comprises the following raw materials: granulated blast furnace slag, gypsum and high belite sulfoaluminate cement clinker. The use of high flexural super sulfate cement can alleviate the problems of slow hydration and hardening speed, low early strength and easy sanding of existing super sulfate cement due to the inability to fully stimulate the activity of granulated blast furnace slag in the prior art, and The flexural strength of cement can be greatly improved, and the high flexural ultra-sulfate cement has the advantages o...

Embodiment 1-5

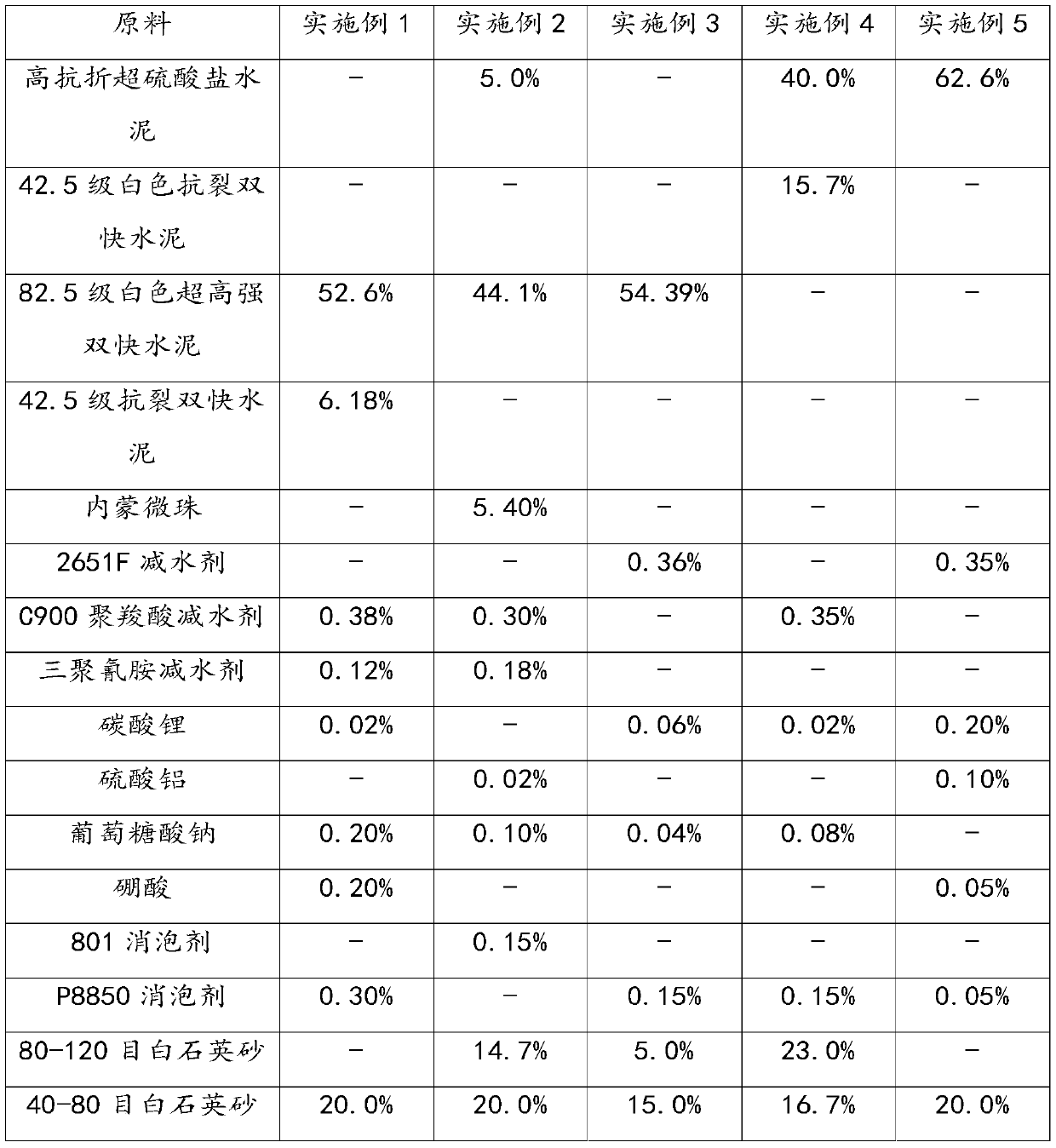

[0099] The low-shrinkage and corrosion-resistant ultra-high-performance concrete of Examples 1-5 is mainly prepared from the following raw materials in weight percentages, and the specific raw material components and ratios are shown in Table 1.

[0100] Table 1 Raw material components and ratios of the low-shrinkage corrosion-resistant ultra-high performance concrete of Examples 1-5

[0101]

[0102]

[0103] Note: "-" in the table means that this kind of raw material was not added in this example (the same below).

Embodiment 6-10

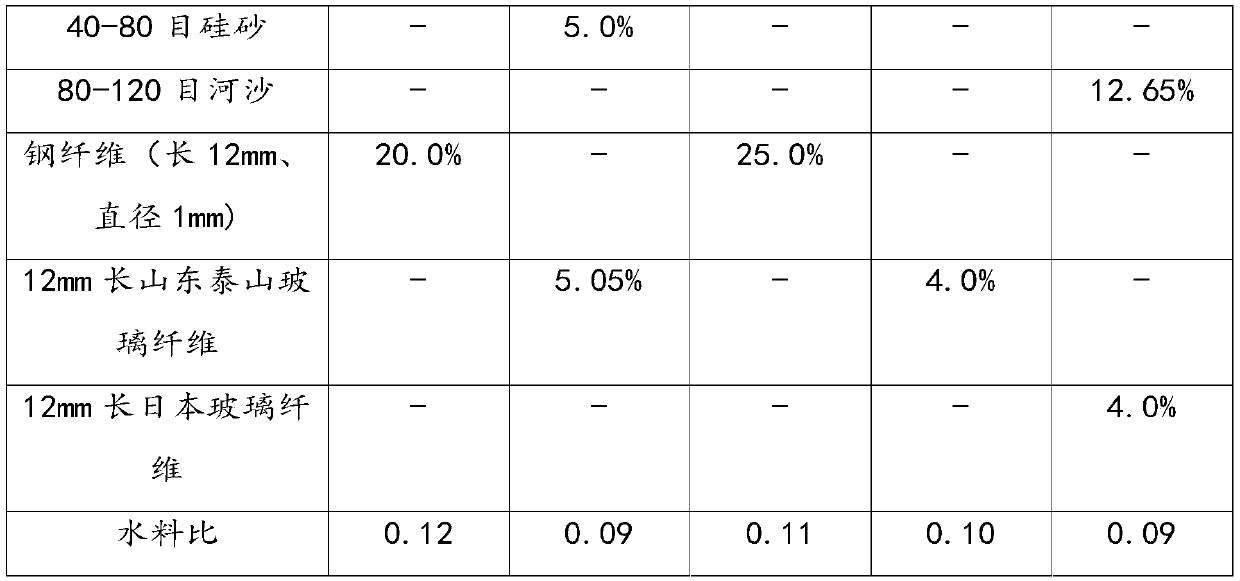

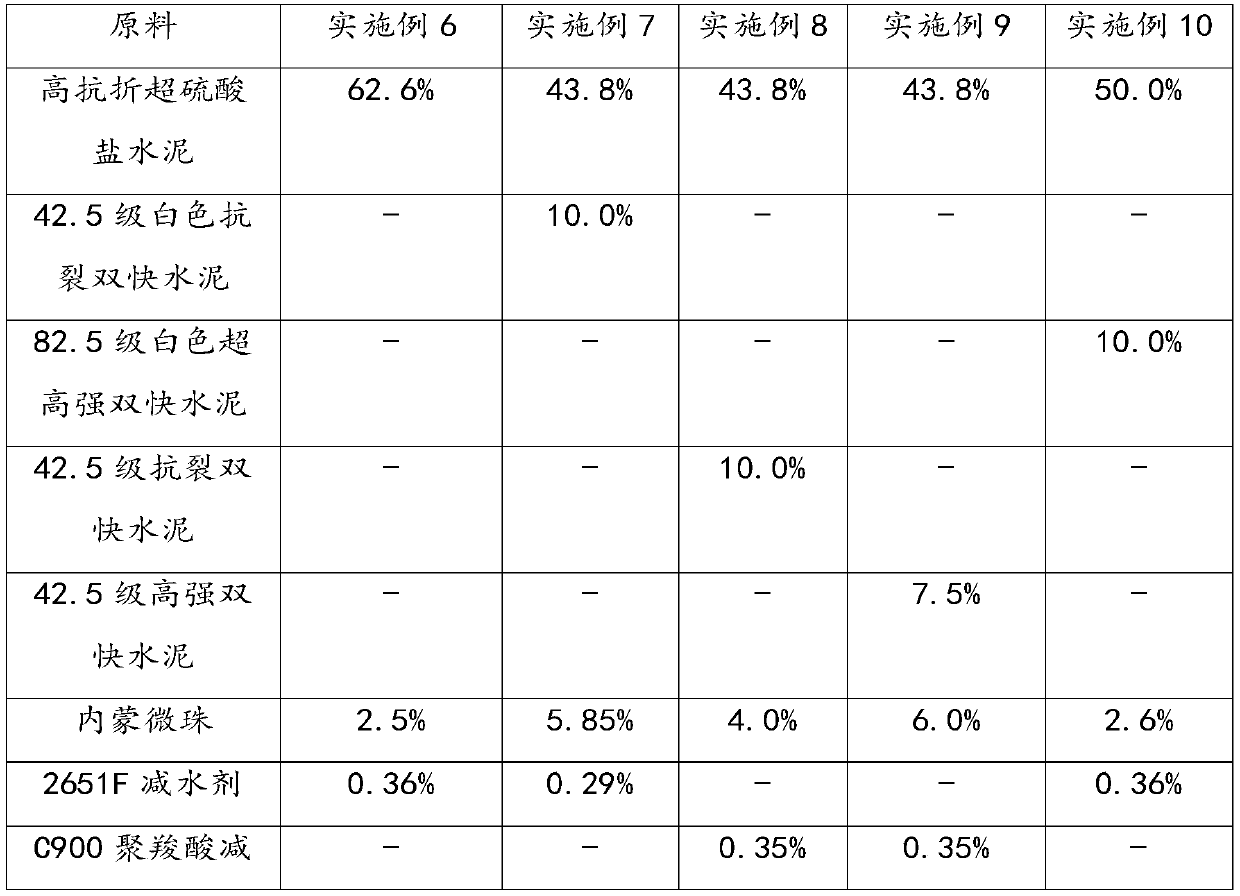

[0105] The low-shrinkage and corrosion-resistant ultra-high-performance concrete of Examples 6-10 is mainly prepared from the following raw materials in weight percentages, and the specific raw material components and ratios are shown in Table 2.

[0106] Table 2 Raw material composition and ratio of the low-shrinkage and corrosion-resistant ultra-high performance concrete of Examples 6-10

[0107]

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com