Preparation method of concrete repairing mortar

A technology for repairing mortar and concrete, which is applied in the field of building materials, can solve the problems of reduced concrete bearing capacity and durability, small shrinkage, and difficulty in maintaining stable repair effects, so as to improve the compressive strength, avoid gradual reduction, and repair effects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

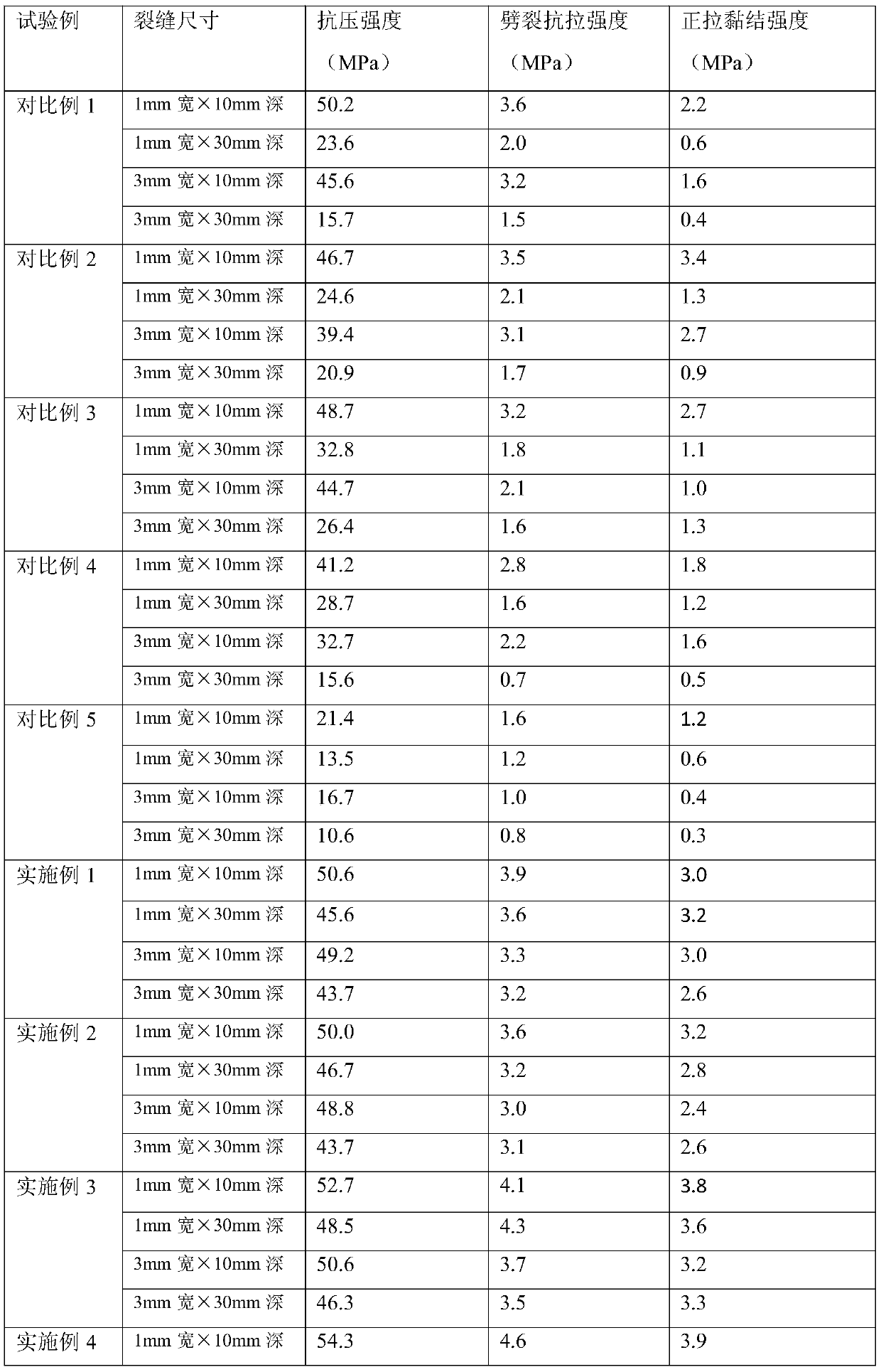

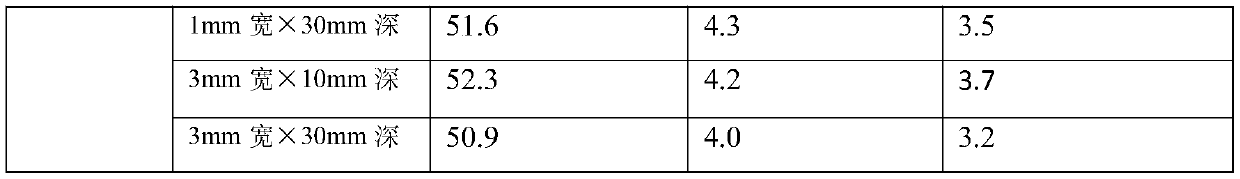

Examples

Embodiment 1

[0045] Prepare concrete repair mortar as follows.

[0046](1) Add 200 ml of 5 mol / L citric acid to 100 g of corn stalk powder (particle size 60 μm), acidify for 2 hours, wash with distilled water until neutral, and dry to obtain acidified straw powder;

[0047] (2) Mix the strain cells, 15% urea solution, 50% calcium acetate solution and 2% sodium alginate solution in a weight ratio of 1:5:6:5, stir at 30°C for 20 minutes, let stand for 32 hours, and mix according to the weight ratio Solution: acidified straw=10:2, add the acidified straw powder obtained in step (1), mix evenly, let it stand for 2 hours, and obtain the repairing liquid, wherein, the strain cells are purified carbonic anhydrase strains in a sterile medium After culturing at 30°C for 48 hours, it was obtained by repeated centrifugation and washing at 2°C. The sterile medium was composed of: peptone 15g / L, yeast powder 20g / L, ammonium sulfate 10g / L, pH 7;

[0048] (3) Mix the repair liquid obtained in step (2) w...

Embodiment 2

[0050] Prepare concrete repair mortar as follows.

[0051] (1) Add 300 ml of 5 mol / L citric acid to 100 g of corn stalk powder (particle size 100 μm), acidify for 1.5 h, wash with distilled water until neutral, and dry to obtain acidified straw powder;

[0052] (2) Mix the strain cells, 15% urea solution, 50% calcium acetate solution and 2% sodium alginate solution in a weight ratio of 1:3:8:6, stir at 30°C for 20 minutes, let stand for 48 hours, and mix according to the weight ratio Solution: acidified straw=10:4, add the acidified straw powder obtained in step (1), mix evenly, and let it stand for 3 hours to obtain a repairing solution, wherein the strain cells are purified carbonic anhydrase strains in a sterile medium After culturing at 30°C for 24 hours, it was obtained by repeated centrifugation and washing at 2°C. The sterile medium consists of: meat extract broth 30g / L, peptone 12g / L, polysaccharide 8g / L, agar 10g / L, pH is 6.5;

[0053] (3) Mix the repair liquid obta...

Embodiment 3

[0055] Prepare concrete repair mortar as follows.

[0056] (1) Add 200 ml of 5 mol / L citric acid to 100 g of corn stalk powder (particle size 120 μm), acidify for 1.5 h, wash with distilled water until neutral, and dry to obtain acidified straw powder;

[0057] (2) Mix the strain cells, 15% urea solution, 50% calcium acetate solution and 2% sodium alginate solution in a weight ratio of 1:4:8:5, stir at 30°C for 20 minutes, let stand for 48 hours, and mix according to the weight ratio Solution: acidified straw=10:3.5 add the acidified straw powder obtained in step (1), after mixing evenly, let it stand for 3 hours to obtain repairing solution, wherein, the strain cells are purified carbonic anhydrase strains in a sterile medium After culturing at 30°C for 48 hours, it was obtained by repeated centrifugation and water washing at 2°C. The sterile medium consists of: meat extract broth 30g / L, peptone 12g / L, polysaccharide 8g / L, agar 10g / L, pH is 6.5;

[0058] (3) Mix the repair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com