Halogen-free epoxy resin composition and preparation method and application thereof

A technology of halogenated epoxy resin and epoxy resin, which is applied in the field of epoxy resin composition and its preparation, can solve the problems of high brittleness, difficult processing, high cost, etc., achieve low thermal expansion coefficient, good peel strength, excellent The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

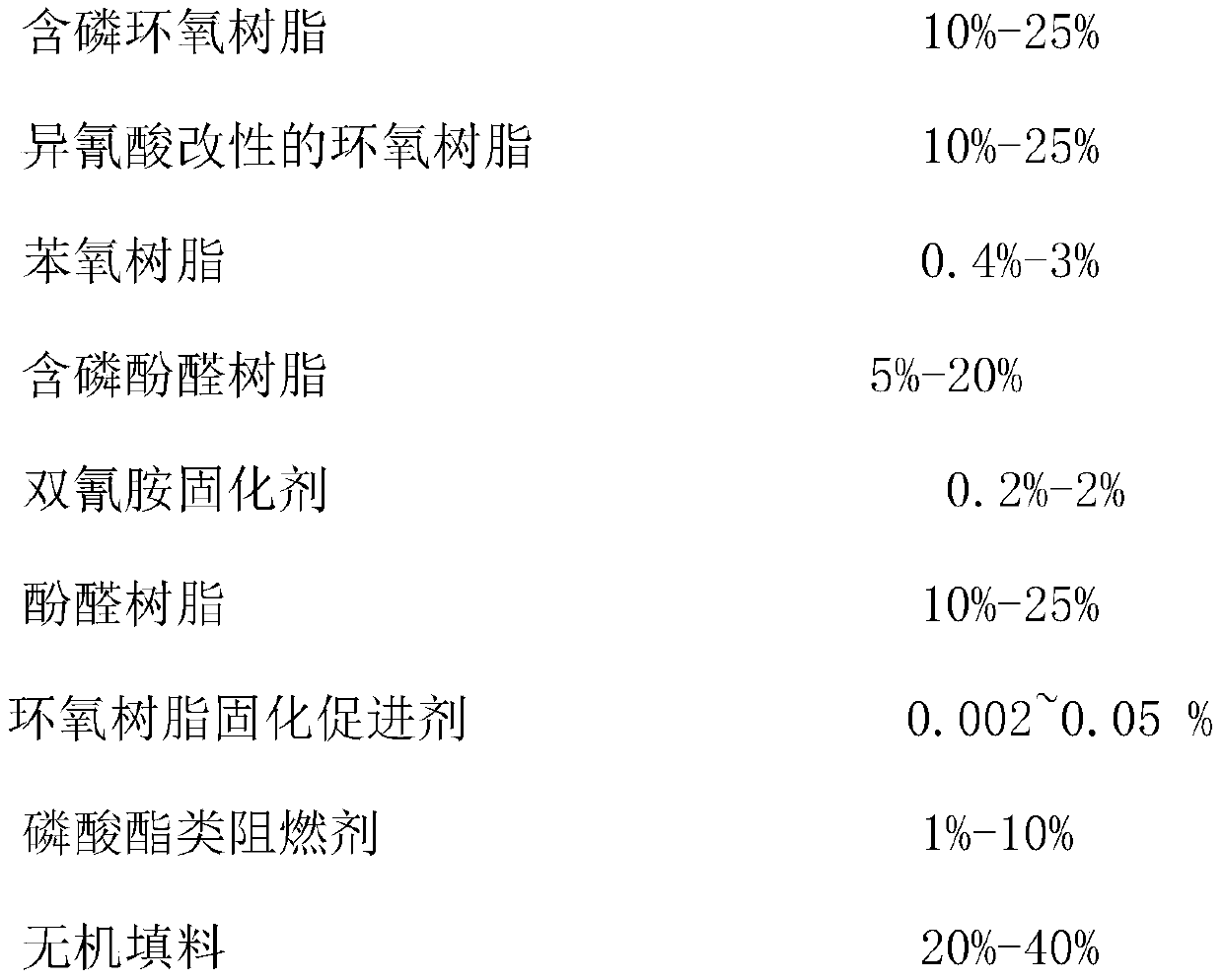

[0063] 1. The mass percent composition of solids in the resin composition is 66%, and all the other are organic solvents (such as propylene glycol methyl ether), wherein, the formula of solids is shown in the following table 1 (by weight)

[0064] Table 1

[0065] raw material

Solid Weight (g)

Phosphorous epoxy resin

22

Isocyanate Modified Epoxy Resin

18

Phenoxy resin

1.5

Phosphorus-containing phenolic resin

15

Phenolic Resin

18

Dicyandiamide curing agent

0.8

2-Ethyl-4-methylimidazole (2E4MZ)

0.005

PX-200

2

silica

20

Aluminum hydroxide

10

[0066] 2. The preparation method of epoxy resin composition:

[0067] (1) Add 55 grams of organic solvent propylene glycol methyl ether and dicyandiamide curing agent, phosphoric acid ester flame retardant in the stirring tank according to the above weight, open the agitator, rotate at 900 rpm, and continue stirr...

Embodiment 2

[0076] 1. The mass percent composition of the solids in the resin composition is 62%, and all the other are organic solvents (such as propylene glycol methyl ether), wherein, the formula of the solids is shown in the following table 3 (by weight)

[0077] table 3

[0078]

[0079] 2. The preparation method of epoxy resin composition:

[0080] (1) Add 70 grams of organic solvent propylene glycol methyl ether, dicyandiamide curing agent, and phosphoric acid ester flame retardant into the stirring tank according to the above weight, turn on the agitator, rotate at 1000 rpm, and continue stirring for 120 minutes until the dicyandiamide The amine curing agent and PX-200 are completely dissolved; then add silicon dioxide and aluminum hydroxide, and keep stirring for 80 minutes after the addition is complete.

[0081] (2) Add phosphorus-containing epoxy resin, isocyanic acid-modified epoxy resin, phenoxy resin, phosphorus-containing phenolic resin, and phenolic resin in sequence ...

Embodiment 3

[0089] 1. The mass percent composition of solids in the resin composition is 69%, and all the other are organic solvents (such as propylene glycol methyl ether), wherein, the formula of solids is shown in the following table 5 (by weight)

[0090] table 5

[0091]

[0092] 2. The preparation method of epoxy resin composition:

[0093] (1) Add 53 grams of organic solvent propylene glycol methyl ether and dicyandiamide curing agent and phosphoric acid ester flame retardant into the stirring tank according to the above weight, turn on the agitator, rotate at 1000 rpm, and continue to stir for 120 minutes until the dicyandiamide The amine curing agent and PX-200 are completely dissolved; then add silicon dioxide and aluminum hydroxide, and keep stirring for 80 minutes after the addition is complete.

[0094] (2) Add phosphorus-containing epoxy resin, isocyanic acid-modified epoxy resin, phenoxy resin, phosphorus-containing phenolic resin, and phenolic resin in sequence accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com