Preparation of recombinant dust mite type I allergen Der p1 and Der f1 protein and application

A technology for allergens and dust mites, applied in the field of industrialized production of recombinant type I allergen Derp1 and Derf1 proteins, can solve the problems of DP1 and DF1 protein expression and fermentation process optimization, unsuitable for large-scale preparation, mature protein harvesting. problems such as low yield, to achieve the effect of increased yield, simple ingredients and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

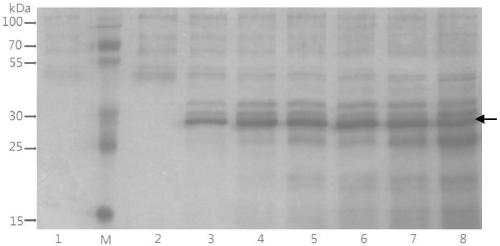

[0058] Embodiment 1 recombinant DP1 / DF1 small-scale (3L) high-density fermentation process

[0059] Step 1: Activation of recombinant strains

[0060] Streak the Glycerol bacteria seeds in the DP1 working seed bank frozen at -80°C on the YPD solid medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L, agarose 15g / L), 30°C Cultivate in a constant temperature and humidity box for 3-5 days.

[0061] Step 2: Seed liquid culture

[0062] Pick the monoclonal colonies on the plate and culture them in YPD liquid medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L) at 30°C and 220rpm until OD 600 ≈6.0, and observe under the microscope that there is no miscellaneous bacteria, and the seed liquid for fermentation is obtained.

[0063] Step 3: Fermentation Process

[0064] Clean the Sartorius B-plus bioreactor, calibrate the pH meter probes of the fermenter with pH=7.0 and pH=4.0 standard solutions, and then configure BSM medium as the fermentation medium (see the ta...

Embodiment 2

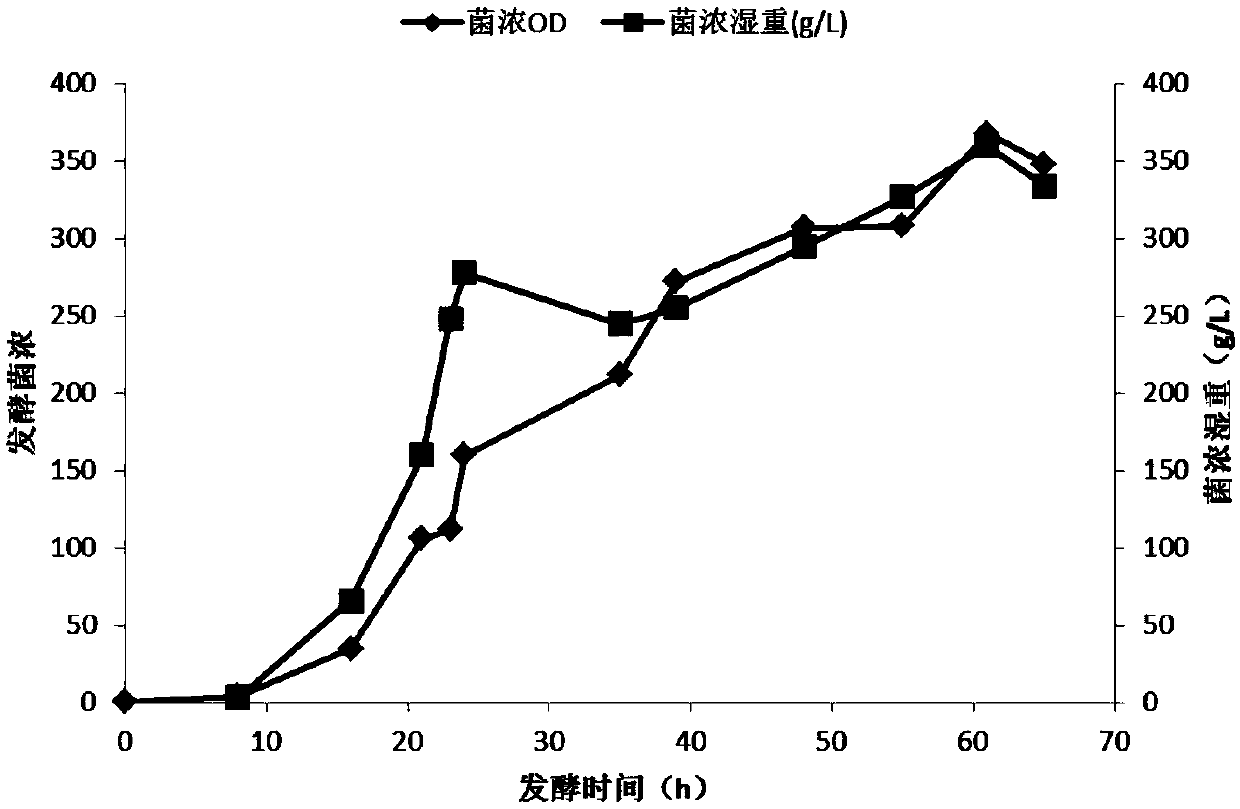

[0070] Example 2 Recombinant DP1 / DF1 large-scale (30L) high-density fermentation verification

[0071] Step 1: Activation of recombinant strains

[0072] Streak the Glycerol bacteria seeds in the working seed bank frozen at -80°C on YPD solid medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L, agarose 15g / L) and keep the temperature at 30°C Cultivate in a humid chamber for 3-5 days.

[0073] Step 2: Primary seed liquid culture

[0074] Pick the monoclonal colonies on the plate in step 1 and culture them in YPD liquid medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L) at 30°C and 220rpm to OD 600 ≈6.0, and observed under a microscope without any bacteria, the first-grade seed liquid for fermentation was obtained.

[0075] Step 3: Secondary Seed Solution Culture

[0076] Inoculate the primary seed liquid obtained in step 2 into the Sartorius B-plus fermenter, and cultivate it with 60% BSM, pH=5.5±0.2, 27°C, 300rpm, and maintain the dissolved oxygen thr...

Embodiment 3

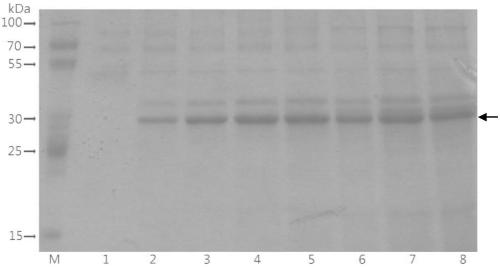

[0081] Example 3 Recombinant DP1 / DF1 Pilot Test (300L) High Density Fermentation Verification

[0082] Step 1: Activation of recombinant strains

[0083] Streak the seeds of glycerol bacteria in the working seed bank frozen at -80°C on YPD slant medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L, agarose 15g / L), and keep the temperature at 30°C Cultivate in a humid chamber for 3-5 days.

[0084] Step 2: Primary seed liquid culture

[0085] Pick the monoclonal colonies on the plate in step 1 and culture them in YPD liquid medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L) at 30°C and 220rpm to OD 600 ≈6.0, and observed under a microscope without any bacteria, the first-grade seed liquid for fermentation was obtained.

[0086] Step 3: Secondary Seed Solution Culture

[0087] Inoculate the primary seed solution obtained in step 2 into a Diwoxin BVT-3000 30L seed tank, and cultivate it with 60% BSM, pH=5.5±0.2, 27°C, 300rpm, and make the solution Oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com