Rapid nitrate detection reagent and detection method

A technology of detection reagents and detection methods, which is applied in the measurement of color/spectral properties, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the difference of test results, poor repeatability, etc. problem, to achieve the effect of good stability, guarantee consistency, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

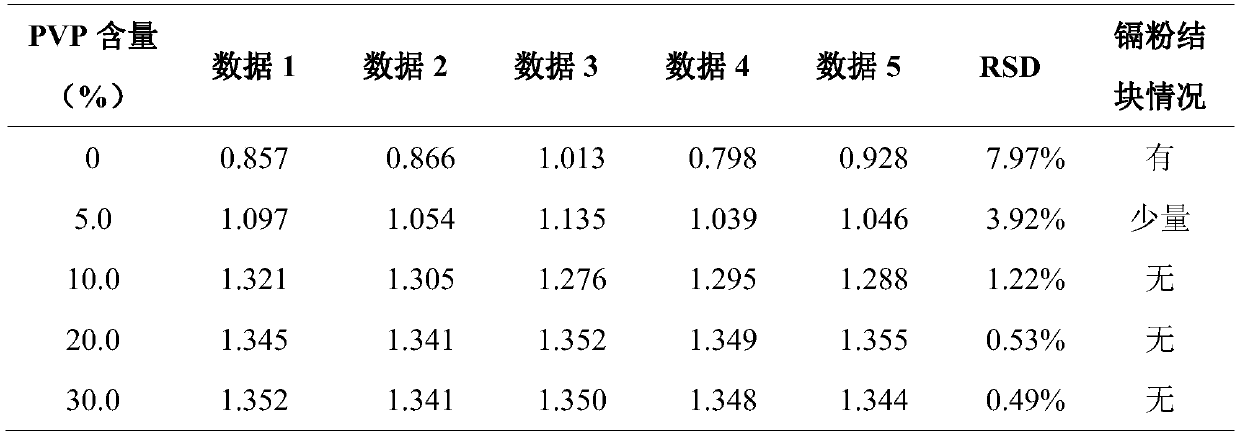

[0030] A quick detection reagent for nitrate, comprising reagent I and reagent II, wherein:

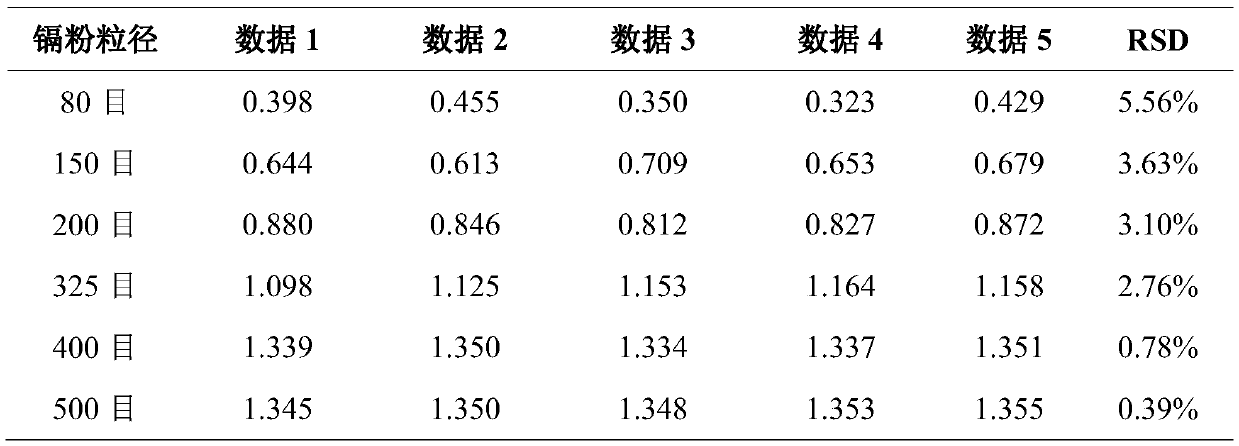

[0031] The reagent I is composed of the following components: tartaric acid: 75.70g, cadmium powder (particle size less than 38 μm): 3.30g, sulfonamide: 1.00g, PVP: 20.00g; fully mix the components in the reagent I, and then Packed on the powder automatic packaging machine, the specification is 0.30g / bag;

[0032] The reagent II is composed of the following components: naphthaleneethylenediamine hydrochloride: 2.00g, tartaric acid: 98.00g; the components in the reagent II are fully mixed and evenly packed, and then packed on a powder automatic packaging machine, the specification is 0.20g / bag .

Embodiment 2

[0034] A quick detection reagent for nitrate, comprising reagent I and reagent II, wherein:

[0035] The reagent I is composed of the following components: tartaric acid: 74.00g, cadmium powder (particle size less than 38 μm): 5.00g, sulfonamide: 1.00g, PVP: 20.00g; fully mix the components in the reagent I, and then Packed on the powder automatic packaging machine, the specification is 0.20g / bag;

[0036] The reagent II is composed of the following components: naphthaleneethylenediamine hydrochloride: 4.00g, tartaric acid: 96.00g; the components in the reagent II are fully mixed and evenly packed, and then packed on an automatic powder packaging machine, the specification is 0.10g / bag .

Embodiment 3

[0038] The production method of the standard color card is as follows:

[0039] 1) Use pure water to prepare nitrates with concentrations of 0.05mg / L, 0.1mg / L, 0.2mg / L, 0.3mg / L, 0.4mg / L, 0.5mg / L, 0.7mg / L, 1.0mg / L Nitrogen (as NO 3 -N meter) standard solution;

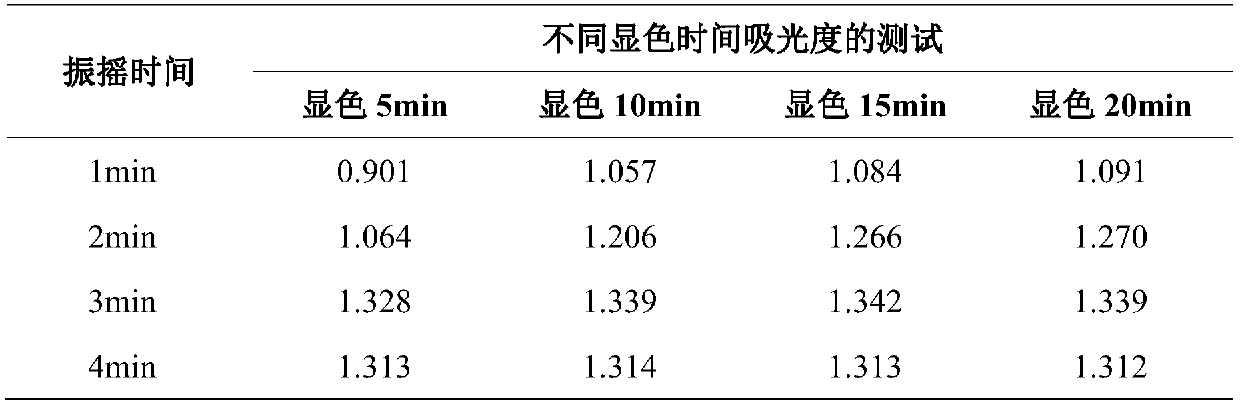

[0040] 2) Add the nitrate nitrogen standard solution with a concentration of 0.05mg / L into the clean colorimetric bottle to the 10mL mark, add 1 pack of reagent I prepared in Example 1, shake on the vortex for 3min, and let it stand for 2min. Then add 1 pack of the reagent II prepared in Example 1, shake it on a vortex meter for 5 minutes, let it stand for 10 minutes, then place the colorimetric bottle on a white PVC plate, observe the color of the solution from the mouth of the bottle, and test it in Pantone Find the corresponding standard color on the color card, and repeat the operation, respectively for the concentrations of 0.1mg / L, 0.2mg / L, 0.3mg / L, 0.4mg / L, 0.5mg / L, 0.7mg / L, 1.0 mg / L nitrate nitrogen standard ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap