A method for analyzing butyl ester components in water-based glue for cigarette packaging

An analysis method, water-based technology, applied in the field of tobacco chemical composition analysis, can solve the problems of lack of precision, good repeatability, good recovery rate, etc., and achieve good repeatability, high sensitivity, and good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1. Preparation of standard solution

[0070] Accurately weigh isobutyl acetate, n-butyl acetate, isobutyl propionate, isobutyl isobutyrate, n-butyl propionate, n-butyl isobutyrate, isobutyl butyrate in a 10mL volumetric flask and 50 mg of n-butyl butyrate (accurate to 0.1 mg), add N,N-dimethylformamide to dissolve and constant volume, and make a first-level mixed standard stock solution with a concentration of 5 mg / mL, and the first-level mixed The standard stock solution is stored in a refrigerator at 4°C in the dark, and the validity period is 6 months.

[0071] Accurately pipette 1mL of the first-level mixed standard stock solution into a 10mL volumetric flask, add N,N-dimethylformamide to dissolve and constant volume, and prepare the second-level mixed standard stock solution with a concentration of 500μg / mL. The grade mixed standard stock solution is stored in a refrigerator at 4°C in the dark, and the validity period is 6 months.

[0072] Pipette a series of sec...

Embodiment 2

[0087] 1. Preparation of standard solution

[0088] Accurately weigh isobutyl acetate, n-butyl acetate, isobutyl propionate, isobutyl isobutyrate, n-butyl propionate, n-butyl isobutyrate, isobutyl butyrate in a 10mL volumetric flask and 50 mg of n-butyl butyrate (accurate to 0.1 mg), add N,N-dimethylformamide to dissolve and constant volume, and make a first-level mixed standard stock solution with a concentration of 5 mg / mL, and the first-level mixed The standard stock solution is stored in a refrigerator at 4°C in the dark, and the validity period is 6 months.

[0089] Accurately pipette 1mL of the first-level mixed standard stock solution into a 10mL volumetric flask, add N,N-dimethylformamide to dissolve and constant volume, and prepare the second-level mixed standard stock solution with a concentration of 500μg / mL. The grade mixed standard stock solution is stored in a refrigerator at 4°C in the dark, and the validity period is 6 months.

[0090]Pipette 50 μL, 100 μL, 2...

Embodiment 3

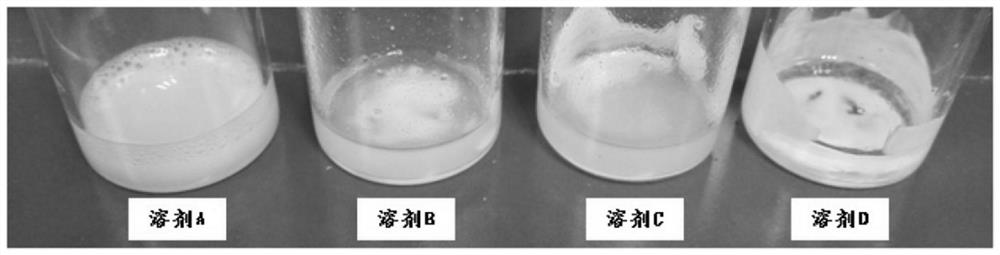

[0107] The 8 kinds of butyl ester components of the target detection object in the present invention are insoluble or slightly soluble in water, and most of them are miscible with various organic solvents such as alcohols, ethers and hydrocarbons. Therefore, after screening, we selected the following four solvents to investigate their solubility in water-based glue for cigarette packaging: A—N,N-dimethylformamide, B—ethanol, C—isopropanol, D—n-hexyl alkyl.

[0108] Weigh four 0.1g (accurate to 0.1mg) samples of water-based adhesive for cigarette packaging of the same type, add 1mL of the above-mentioned four solvents A, B, C, and D respectively, and observe the degree of dissolution of the water-based adhesive. For specific results, see figure 1 . like figure 1 As shown, the experimental results show that the water-based glue for cigarette packaging can be quickly and completely dissolved in solvent A with a little manual shaking; in solvents B and C, it is only slightly sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com