A kind of preparation method of graphene monopolar plate with high electrical conductivity, high thermal conductivity, high air tightness and corrosion resistance and hydrogen fuel cell

A fuel cell and graphene technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve the problems of low hydrogen utilization rate, low electrical conductivity, and low thermal conductivity of bipolar plates, and achieve high crystallinity and electrical conductivity Effects of improved performance and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

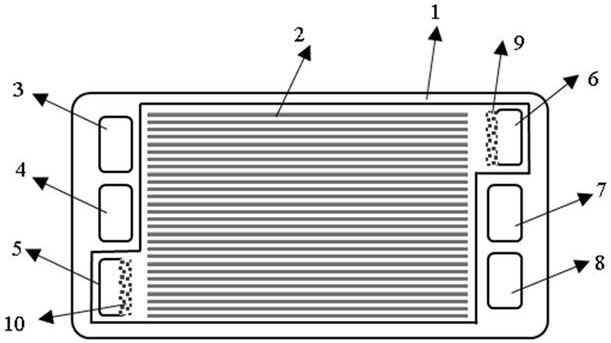

[0027] Specific embodiment one: what this embodiment records is a kind of preparation method of high electrical conductivity, high thermal conductivity, high air tightness and corrosion-resistant graphene unipolar plate, and the steps of the method are as follows:

[0028] Step 1: Mold preparation: Prepare the corresponding graphite mold according to the shape and size of the unipolar plate, and the graphite is high-strength graphite;

[0029] Step 2: Filling: spread the graphene powder evenly in the graphite mold, and scrape the surface;

[0030] Step 3: Preforming: Use a press to apply a pressure of 0.5~1MPa to the filler in step 2 at room temperature, pressurize at a constant speed of 5~20mm / min, and keep the pressure for 1~5min after reaching the given pressure Preformed into a graphene plate and taken out from the mold; the preforming process can discharge most of the gas inside the powder, and during the process of gas discharge, the flow of the gas can drive the graphen...

specific Embodiment approach 2

[0034] Specific embodiment two: the preparation method of a kind of high electrical conductivity, high thermal conductivity, high air-tightness and corrosion-resistant graphene unipolar plate described in specific embodiment one, in step five, described hot pressing sintering is: from room temperature to 8 ~ The heating rate of 20 ℃ / min is raised to 600 ℃ ~ 2500 ℃, pressurized, the pressure is 20MPa ~ 60MPa, the heat preservation and pressure holding time is 30 ~ 120min, the whole hot pressing sintering process is carried out in a vacuum environment or an inert atmosphere.

specific Embodiment approach 3

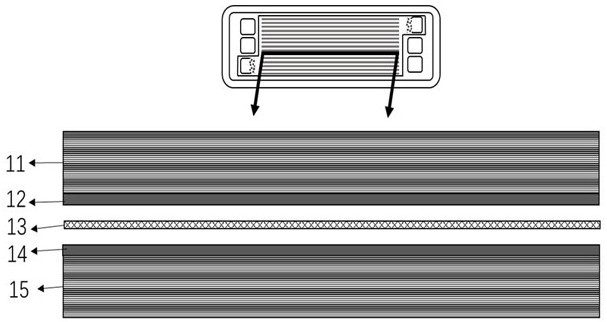

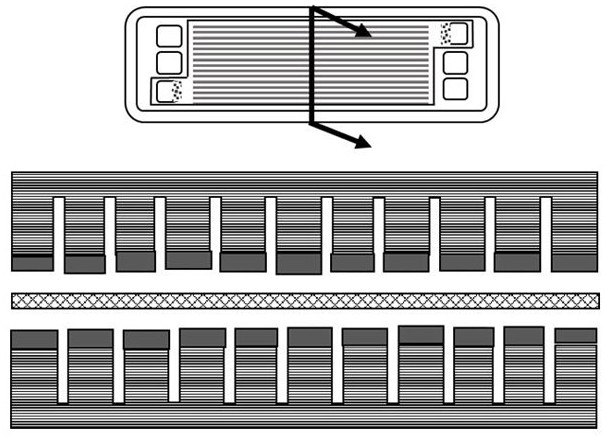

[0035] Specific embodiment three: the preparation method of a high-conductivity, high-thermal-conductivity, high-air-tightness and corrosion-resistant graphene monopolar plate described in specific embodiment one, inside the graphene bipolar plate, graphene is along the plane direction (XY direction) Highly directional arrangement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com