A kind of preparation method and application of solid acid catalyzed C4 alkylation catalyst

An acid-catalyzed carbon and tetraalkyl technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve unfavorable separation of alkylated oil products, easy Problems such as deactivation of carbon deposits and restrictions on industrial applications, to achieve the effect of reducing the deactivation rate of catalytic carbon deposits, increasing the hydrogen transfer rate, and increasing the hydrogen transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

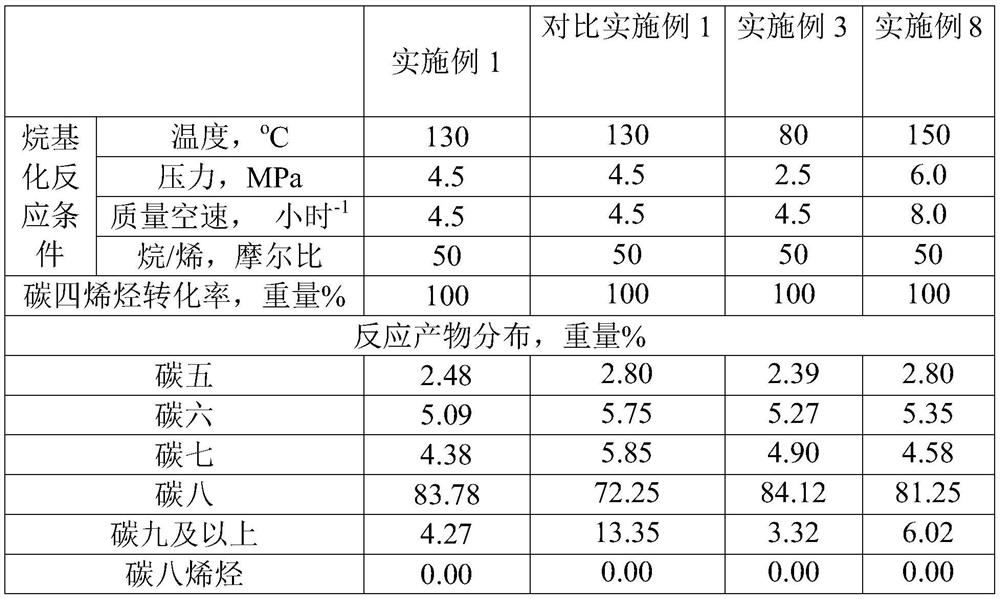

Examples

Embodiment 1

[0018] 50.7mL tetraethyl orthosilicate, 2.5mL hexadecyl long organosilane quaternary ammonium salt ((CH 3 O) 3 SiC 3 h 6 N(CH 3 ) 2 C 16 h 33 Cl) and 91mL of 0.5mol / L tetrapropylammonium hydroxide aqueous solution were added to a 250mL round bottom flask, stirred and hydrolyzed at 35°C for 2h, then added aluminum nitrate according to Si / Al=50, stirred for another 30 minutes, and then pressed 0.5 Add potassium chloroplatinite at wt% load, add iron porphyrin at 2wt% load, add phosphotungstic acid at 10wt% load, continue stirring for 2 hours, and then transfer to a stainless steel crystallization kettle with a polytetrafluoroethylene liner , crystallized at 250°C for 72h, filtered with suction, dried, and calcined at 500°C to remove tetrapropylammonium hydroxide to obtain Pt-Fe-HPA / ZSM-5 catalyst.

Embodiment 2

[0021] Embodiment 2: heteropoly acid type and load

[0022] 50.7mL tetraethyl orthosilicate, 2.5mL hexadecyl long organosilane quaternary ammonium salt ((CH 3 O) 3 SiC 3 h 6 N(CH 3 ) 2 C 16 h 33 Cl) and 91mL of 0.5mol / L tetrapropylammonium hydroxide aqueous solution were added to a 250mL round bottom flask, stirred and hydrolyzed at 35°C for 2h, then added aluminum nitrate according to Si / Al=50, stirred for another 30 minutes, and then pressed 0.5 Add potassium chloroplatinite at wt% load, add iron porphyrin at 2wt% load, add silicotungstic acid at 40wt% load, continue stirring for 2 hours, and then transfer to a stainless steel crystallization kettle with a polytetrafluoroethylene liner , crystallized at 250°C for 72h, filtered with suction, dried, and calcined at 500°C to remove tetrapropylammonium hydroxide to obtain Pt-Fe-HPA / ZSM-5 catalyst.

Embodiment 3

[0023] Embodiment 3: heteropoly acid type and load

[0024] 50.7mL tetraethyl orthosilicate, 2.5mL hexadecyl long organosilane quaternary ammonium salt ((CH 3 O) 3 SiC 3 h 6 N(CH 3 ) 2 C 16 h 33 Cl) and 91mL of 0.5mol / L tetrapropylammonium hydroxide aqueous solution were added to a 250mL round bottom flask, stirred and hydrolyzed at 35°C for 2h, then added aluminum nitrate according to Si / Al=50, stirred for another 30 minutes, and then pressed 0.5 Add potassium chloroplatinite at wt% load, add iron porphyrin at 2wt% load, add germanium tungstic acid at 5wt% load, continue to stir for 2 hours, and then transfer to a stainless steel crystallization kettle with a polytetrafluoroethylene liner , crystallized at 250°C for 72h, filtered with suction, dried, and calcined at 500°C to remove tetrapropylammonium hydroxide to obtain Pt-Fe-HPA / ZSM-5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com