Method for preparing solar polycrystalline silicon wafer

A polycrystalline silicon wafer, solar energy technology, applied in chemical instruments and methods, silicon, silicon compounds, etc., can solve problems such as poor environmental protection and waste of resources, and achieve the effects of strong environmental protection and energy saving, resource saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

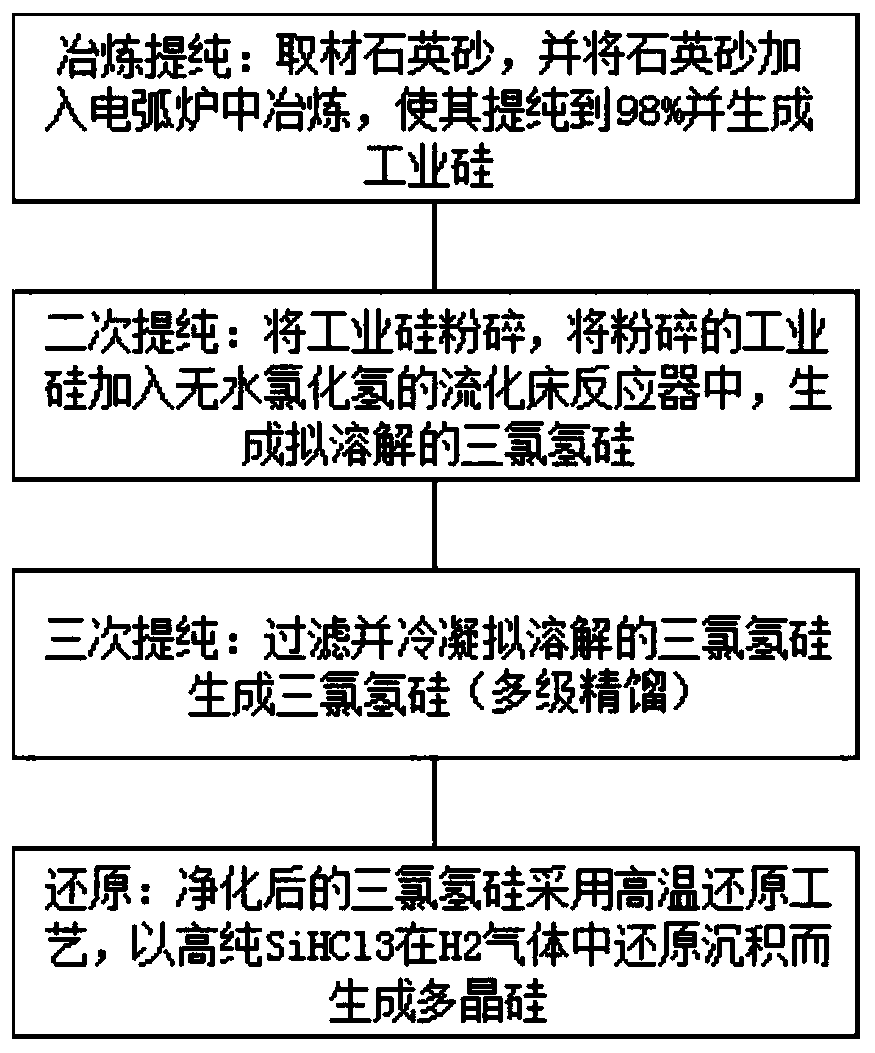

[0040] Such as figure 1 shown, including the following steps:

[0041] (1), smelting and purification: take quartz sand as material, and add the quartz sand to the electric arc furnace for smelting, make it purified to 98% and generate industrial silicon;

[0042] (2), secondary purification: pulverize industrial silicon, add the pulverized industrial silicon in the fluidized bed reactor of anhydrous hydrogen chloride, generate trichlorosilane to be dissolved;

[0043] (3), three times of purification: filter and condense the trichlorosilane to be dissolved to generate trichlorosilane (multistage rectification);

[0044] (4), reduction: the purified trichlorosilane adopts a high-temperature reduction process, and uses high-purity SiHCl 3 Reductive deposition in H2 gas produces polysilicon.

[0045] Smelting and purifying in the described step (1) comprises the following steps:

[0046] (1.1), quartz sand is taken as material;

[0047] (1.2), add quartz sand into the elect...

Embodiment 2

[0066] Include the following steps:

[0067] (1), smelting and purification: take quartz sand as material, and add the quartz sand to the electric arc furnace for smelting, make it purified to 98% and generate industrial silicon;

[0068] (2), secondary purification: pulverize industrial silicon, add the pulverized industrial silicon in the fluidized bed reactor of anhydrous hydrogen chloride, generate trichlorosilane to be dissolved;

[0069] (3), three times of purification: filter and condense the trichlorosilane to be dissolved to generate trichlorosilane (multistage rectification);

[0070] (4), reduction: the purified trichlorosilane adopts a high-temperature reduction process, and uses high-purity SiHCl 3 Reductive deposition in H2 gas produces polysilicon.

[0071] Smelting and purifying in the described step (1) comprises the following steps:

[0072] (1.1), quartz sand is taken as material;

[0073] (1.2), add quartz sand into the electric arc furnace for refinin...

Embodiment 3

[0092] Such as figure 1 shown, including the following steps:

[0093] (1), smelting and purification: take quartz sand as material, and add the quartz sand to the electric arc furnace for smelting, make it purified to 98% and generate industrial silicon;

[0094] (2), secondary purification: pulverize industrial silicon, add the pulverized industrial silicon in the fluidized bed reactor of anhydrous hydrogen chloride, generate trichlorosilane to be dissolved;

[0095] (3), three times of purification: filter and condense the trichlorosilane to be dissolved to generate trichlorosilane (multistage rectification);

[0096] (4), reduction: the purified trichlorosilane adopts a high-temperature reduction process, and uses high-purity SiHCl 3 Reductive deposition in H2 gas produces polysilicon.

[0097] Smelting and purifying in the described step (1) comprises the following steps:

[0098] (1.1), quartz sand is taken as material;

[0099] (1.2), add quartz sand into the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com