Preparation method of water-resistant fruit-cultivating bag paper material

A technology of fruit bag paper and water resistance, which is applied in the field of materials, can solve the problems of poor quality and water resistance of fruit bag paper, and achieve the effects of improving wet strength, increasing wet strength, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

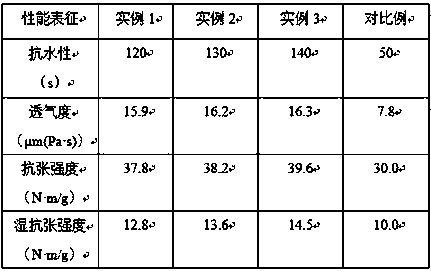

Examples

example 1

[0035] Add natural coniferous wood pulp to waste newspaper pulp, stir at 300r / min for 20min at normal temperature to obtain a mixed slurry; add anhydrous aluminum sulfate to deionized water, stir at 200r / min for 5min at normal temperature to obtain sulfuric acid Aluminum solution, calcium carbonate powder, cationic disperse rosin gum, paraffin wax emulsion, melamine formaldehyde resin and aluminum sulfate solution are added to the mixed slurry, and stirred at a speed of 500r / min for 1h at room temperature to obtain the prepared slurry; The slurry is placed on the paper forming net to form a wet paper sheet, and the wet paper sheet is dehydrated and peeled off, and placed on a press for dehydration under a pressure of 4 MPa for 3 minutes to obtain a dehydrated paper sheet; the dehydrated paper sheet is placed in vacuum drying Dry it in the machine for 4 minutes under the conditions of vacuum degree 92kPa and temperature 60°C, take it out, and obtain water-resistant fruit bag pap...

example 2

[0037] Add natural coniferous wood pulp to waste newspaper pulp, and stir at 350r / min for 25 minutes at room temperature to obtain a mixed slurry; add anhydrous aluminum sulfate to deionized water, and stir at 250r / min for 7 minutes at room temperature to obtain sulfuric acid Aluminum solution, calcium carbonate powder, cationic disperse rosin gum, paraffin wax emulsion, melamine formaldehyde resin and aluminum sulfate solution are added to the mixed slurry, stirred at 550r / min for 1.3h at room temperature, and the prepared slurry is obtained; Put the slurry on the paper forming net to copy into wet paper sheets, remove the wet paper sheets after dehydration, and put them on a press for dehydration for 4 minutes under a pressure of 4.5 MPa to obtain dehydrated paper sheets; place the dehydrated paper sheets in Dry in a vacuum dryer for 5 minutes under the conditions of a vacuum degree of 94kPa and a temperature of 70°C, and take it out to obtain a water-resistant fruit bag pape...

example 3

[0039] Add natural coniferous wood pulp to waste newspaper pulp, stir at 400r / min for 30min at normal temperature to obtain a mixed slurry; add anhydrous aluminum sulfate to deionized water, stir at 300r / min for 10min at normal temperature to obtain sulfuric acid Aluminum solution, calcium carbonate powder, cationic disperse rosin gum, paraffin wax emulsion, melamine formaldehyde resin and aluminum sulfate solution are added to the mixed slurry, stirred at 600r / min for 1.5h at room temperature, and the prepared slurry is obtained; Put the slurry on the paper forming net to copy into wet paper sheets, dehydrate the wet paper sheets, remove them, and place them on a press for dehydration for 5 minutes under a pressure of 5 MPa to obtain dehydrated paper sheets; place the dehydrated paper sheets in a vacuum Dried in a dryer for 6 minutes under the conditions of a vacuum degree of 96kPa and a temperature of 80°C, and took it out to obtain a water-resistant fruit bag paper material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com