Hollow fiber nanofiltration membrane and preparation method thereof

A nanofiltration membrane and fiber technology, applied in the field of membrane separation, can solve the problems of not reaching the level of commercial mass production, complicated preparation steps of composite nanofiltration membrane, low production efficiency, etc., achieving high production efficiency, inhibiting bacterial growth, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a hollow fiber nanofiltration membrane, comprising the following steps:

[0025] Step 1) Take 1 part of polyacrylonitrile with a degree of polymerization of 600, 0.02 parts of nano-bamboo charcoal fiber, 4 parts of dispersant, 0.01 part of hydroxymethyl cellulose, and 20 parts of dimethylformamide according to parts by mass, and add them to the reaction kettle and heat After stirring for 30 minutes under the same conditions, add 0.01 part of nano-silver powder and continue stirring for 45 minutes to form a uniform and stable film-forming solution;

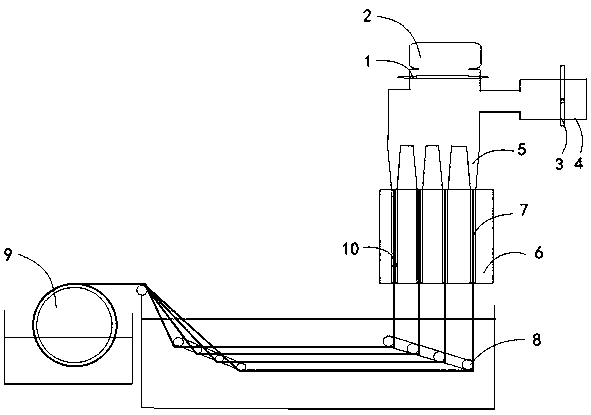

[0026] Step 2) After vacuum degassing the film-forming liquid obtained in step 1), the film-forming liquid is injected into the multi-channel hollow fiber mold through the flow pipe under the drive of air pressure. Under a certain flow rate of the film-forming liquid, spray The output material enters the external coagulation bath after passing through the air gap with a length of 1m, such as figure 1...

Embodiment 2

[0030] A preparation method of a hollow fiber nanofiltration membrane, comprising the following steps:

[0031] Step 1) Take 1.5 parts of polyacrylonitrile with a degree of polymerization of 1200, 0.02 parts of nano-bamboo charcoal fiber, 3 parts of dispersant, 0.02 part of hydroxymethyl cellulose, and 24 parts of dimethylformamide according to parts by mass, add them to the reaction kettle and heat After stirring for 45 minutes under the same conditions, add 0.01 part of nano-silver powder and continue stirring for 50 minutes to form a uniform and stable film-forming solution;

[0032]Step 2) After vacuum degassing the film-forming liquid obtained in step 1), the film-forming liquid is injected into the multi-channel hollow fiber mold through the flow pipe under the drive of air pressure. Under a certain flow rate of the film-forming liquid, spray The discharged material enters the external coagulation bath after passing through the air gap with a length of 1.1m, flows 5m in ...

Embodiment 3

[0036] A preparation method of a hollow fiber nanofiltration membrane, comprising the following steps:

[0037] Step 1) Take 1 part of polyacrylonitrile with a degree of polymerization of 3600, 0.02 part of nano-bamboo charcoal fiber, 4 parts of dispersant, 0.05 part of hydroxymethyl cellulose, and 25 parts of N-methylpyrrolidone according to parts by mass and add them to the reaction kettle and heat After stirring for 50 minutes under the same conditions, add 0.015 parts of nano-silver powder and continue stirring for 60 minutes to form a uniform and stable film-forming solution;

[0038] Step 2) After vacuum degassing the film-forming liquid obtained in step 1), the film-forming liquid is injected into the multi-channel hollow fiber mold through the flow pipe under the drive of air pressure. Under a certain flow rate of the film-forming liquid, spray The discharged material enters the external coagulation bath after passing through the air gap with a length of 1.2m, flows 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com