Two-dimensional layered porous hexagonal nanometer titanium dioxide and preparation method and application thereof

A nano-titanium dioxide, two-dimensional layered technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as no two-dimensional layered porous hexagonal nano-TiO2, etc., to achieve repeatability Good and photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, pour TiSe into a quartz crucible 2 Powder, put it on the heating table; then, feed nitrogen flow rate 80mL / min, air flow rate 20mL / min, set heating temperature to 500°C, heat preservation time to 2h, after the reaction, cool to room temperature with the furnace, white The powder is the target product TiO 2 .

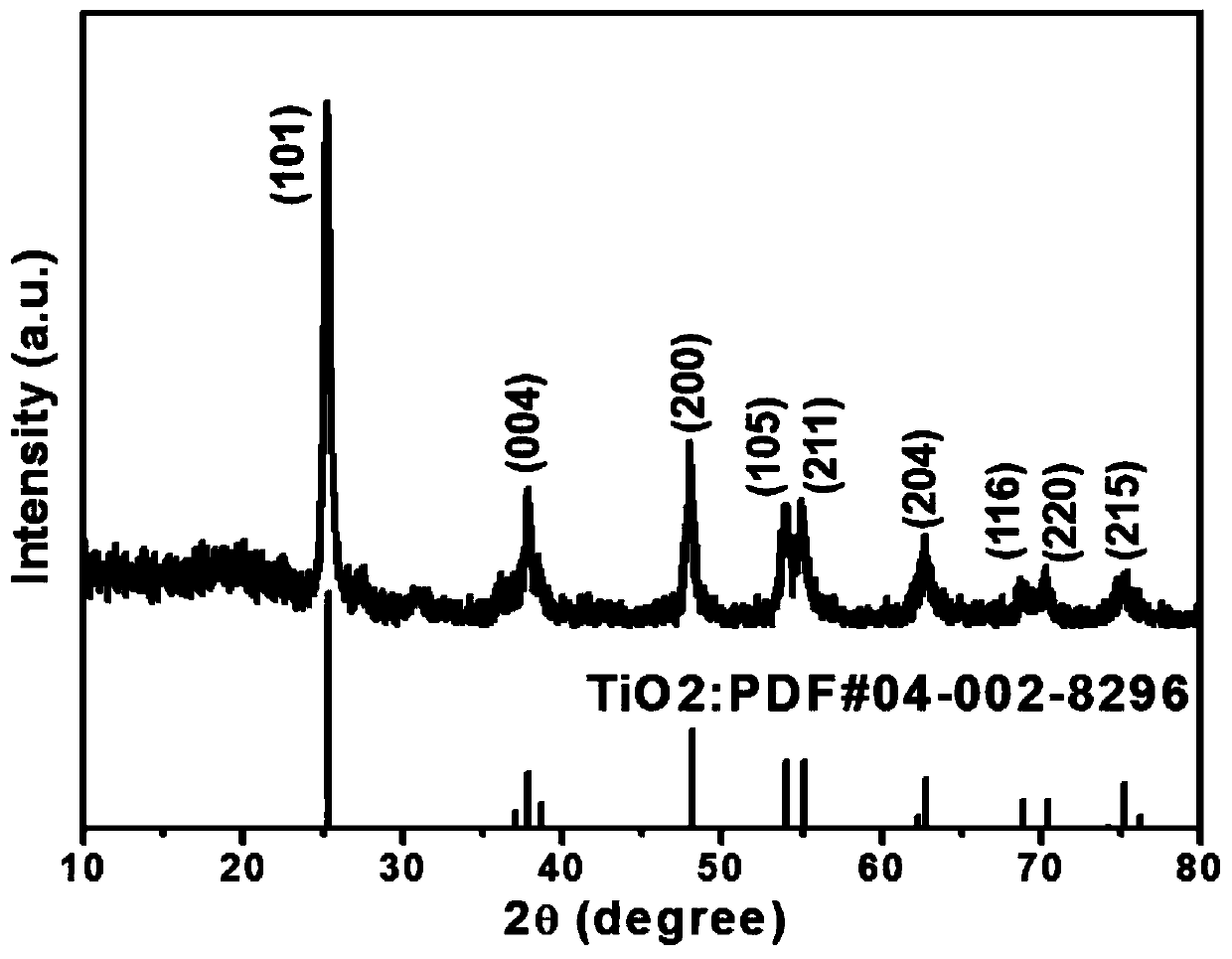

[0036] figure 1 It is the TiO grown according to Example 1 2 In the X-ray diffraction spectrum of nanosheets, no impurity peaks appear, indicating that the product is pure TiO 2 .

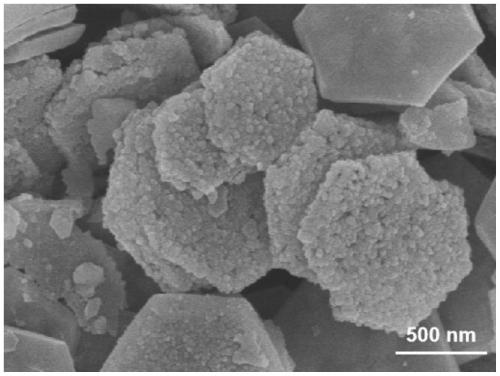

[0037] figure 2 It is the TiO grown according to Example 1 2 SEM topography photos, it can be seen that TiO 2 It has a distinct hexagonal outline and a nanoparticle-like surface.

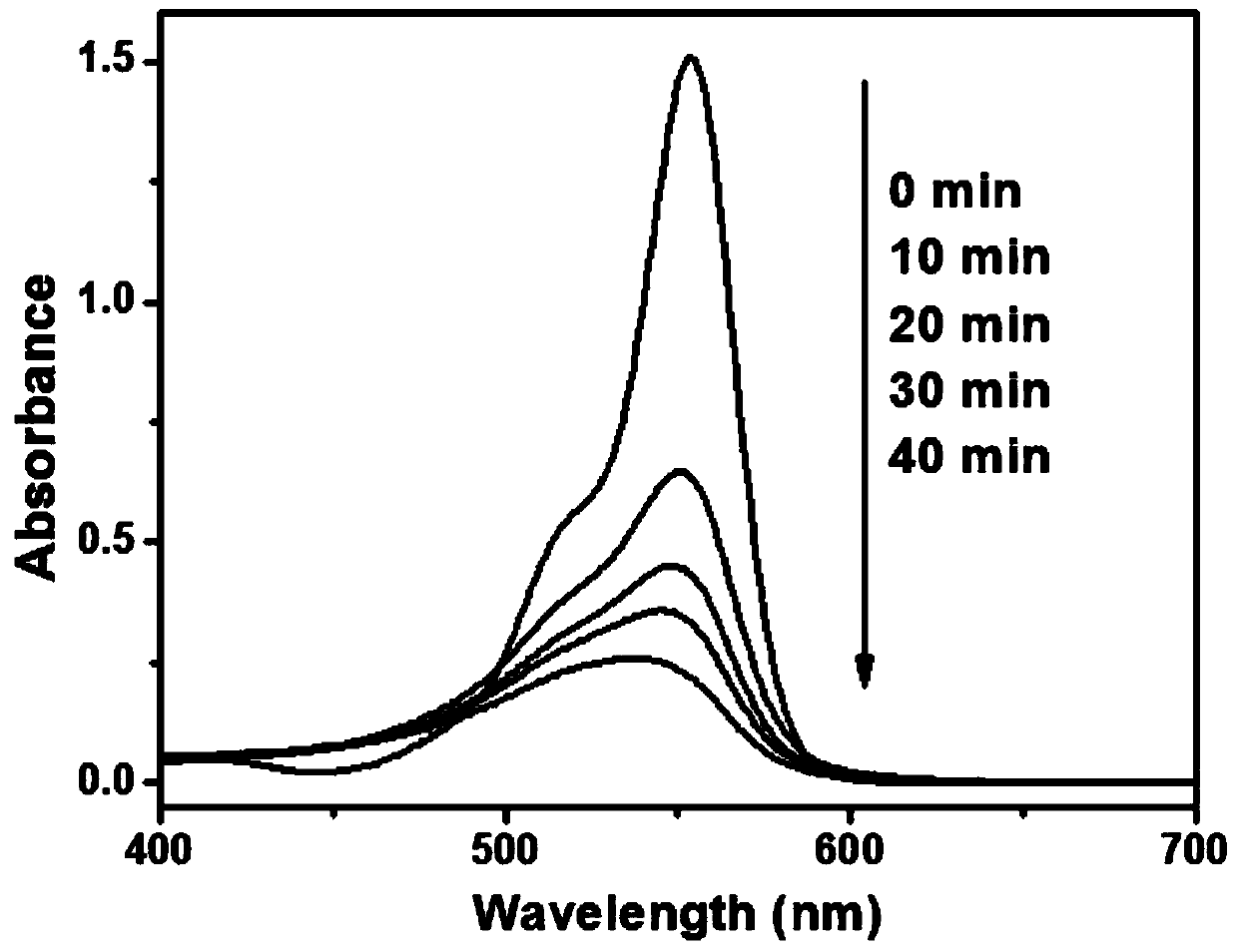

[0038] image 3 It is the visible light absorption picture of Example 1. As the visible light time increases, it is obvious that the absorption peak decreases, indicating that Rh B is constantly being degraded.

[0039] Figure 4 It is the absorptivity picture of Example 1, and it can be s...

Embodiment 2

[0041]Pour TiSe into a quartz crucible 2 Put the powder on the heating platform; the flow rate of argon gas is 30mL / min; the air flow rate is 10mL / min, the heating temperature is set to 300°C, and the holding time is 1h. After the reaction is completed, it is cooled to room temperature with the furnace, white The powder is the target product TiO 2 .

[0042] Figure 5 It is TiO grown according to Example 2 2 X-ray diffraction spectrum, no impurity peaks appear, indicating that the product is pure TiO 2 .

[0043] Figure 6 is the TiO corresponding to Example 2 2 The SEM topography photos, it can be seen that the layered stacked hexagonal TiO 2 There are obvious particles and holes.

Embodiment 3

[0045] Pour TiSe into a quartz crucible 2 Put the powder on the heating platform; the nitrogen flow rate is 10mL / min; the air flow rate is 100mL / min, the heating temperature is set to 450 °C, and the holding time is 5h. After the reaction is completed, it is cooled to room temperature with the furnace, and the white powder body is the target product TiO 2 .

[0046] Figure 7 It is the TiO grown according to Example 3 2 X-ray diffraction spectrum, no impurity peaks appear, indicating that the product is pure TiO 2 , and good crystallinity.

[0047] Figure 8 It is the TiO grown according to Example 3 2 SEM image of nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com