Environment friendly varnished wire or cable flame-retardant paint

A flame retardant coating and enameled wire technology, applied in the field of coatings, can solve the problems of unsatisfactory adhesion or bending resistance or cold and heat cycle resistance, poor flame retardant performance, etc., to eliminate fire hazards and personal injury, The effect of convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

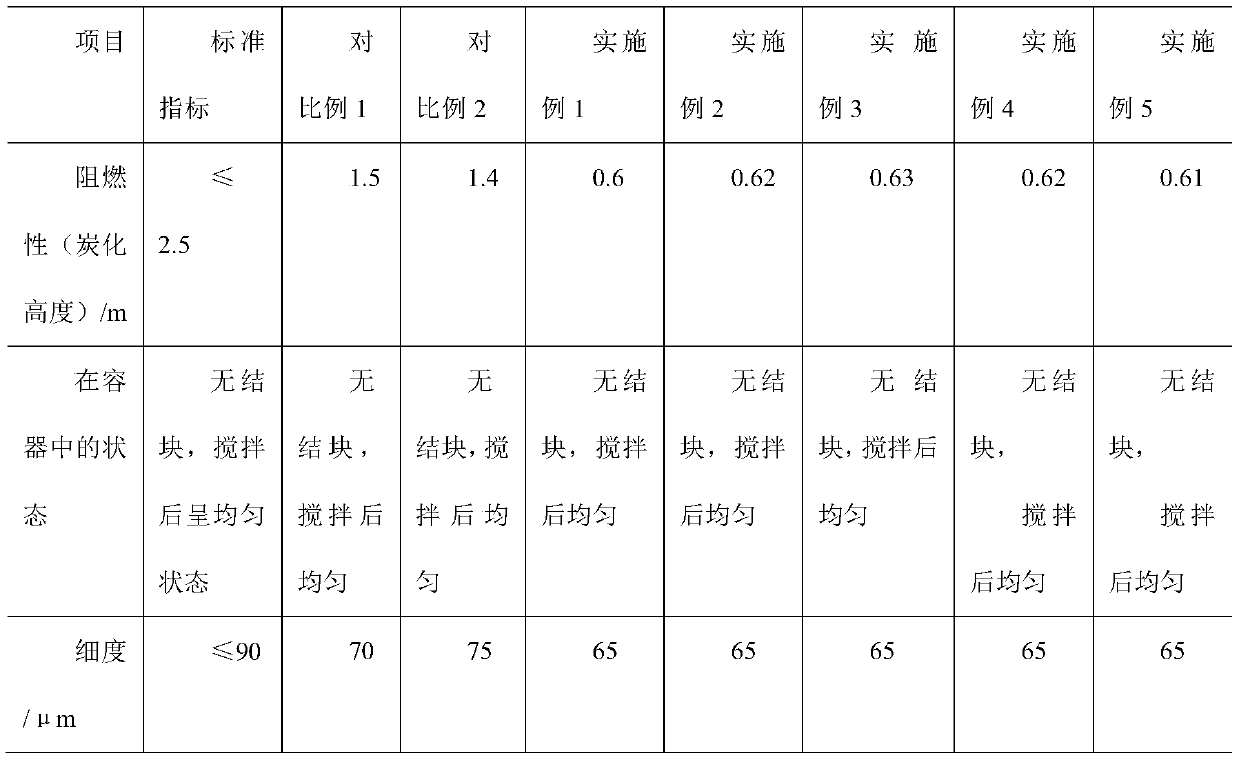

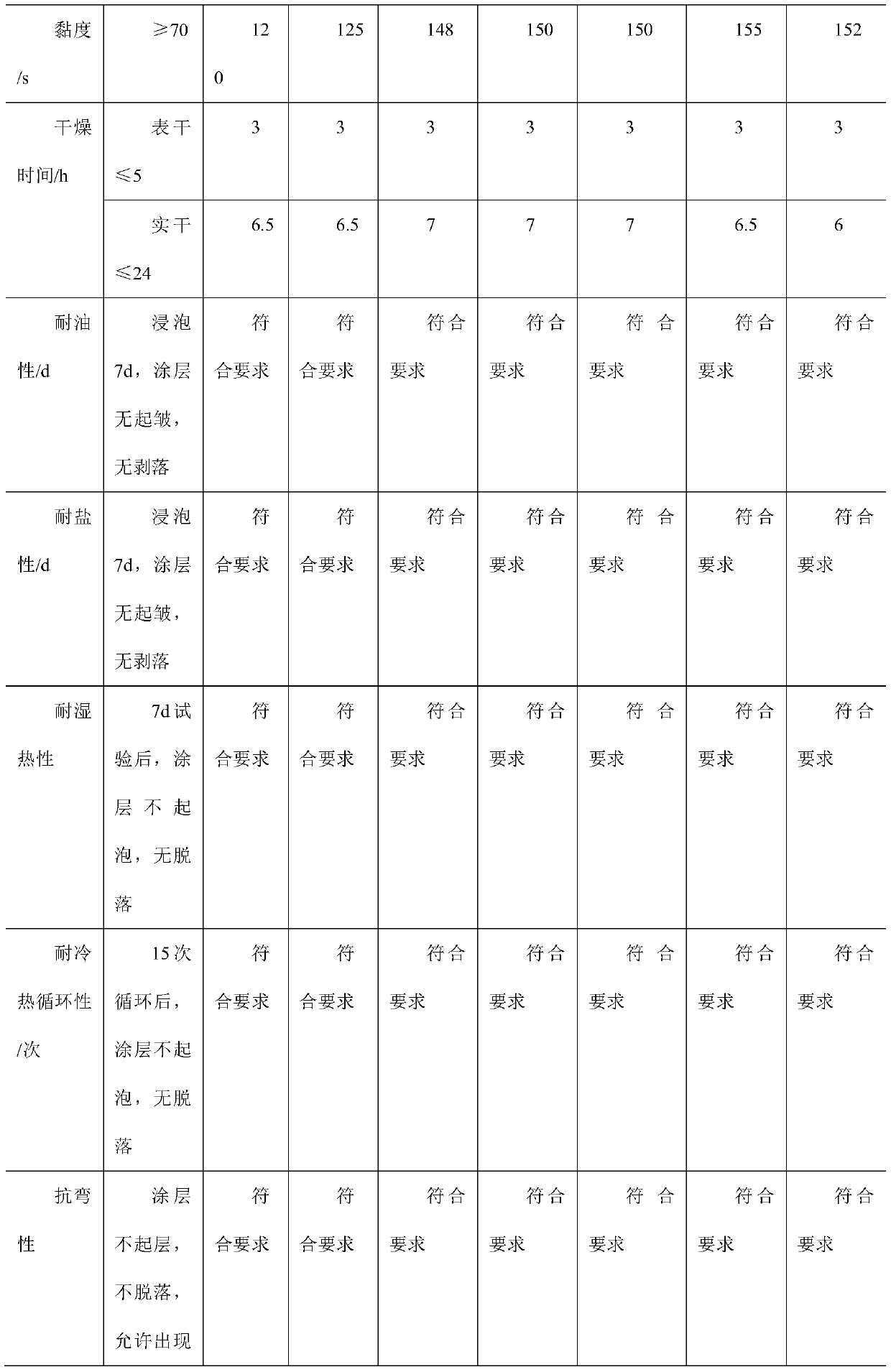

Embodiment 1

[0018] Weighing in parts by weight, 30 parts of water, 1 part of OP-10, 2 parts of dioctyl phthalate, 35 parts of flame retardant (diethylphosphinate aluminum, melamine, polyphosphoric acid Ammonium, rutile titanium dioxide, calcium carbonate, talcum powder, and dipentaerythritol are mixed according to the mass ratio of 2:2:2:1:0.5:0.5:1) and put into the grinding and dispersing machine for grinding for 2 hours; then add 25 acrylate Emulsion, 7 parts of low molecular weight polyethylene wax (2000-3000), disperse at high speed (1200r / min) for 30 minutes to get the coating.

Embodiment 2

[0020] Weighing in parts by weight, 35 parts of water, 1 part of OP-10, 1 part of dioctyl phthalate, 38 parts of flame retardant (diethylphosphinate aluminum, melamine, polyphosphoric acid Ammonium, rutile titanium dioxide, aluminum hydroxide, zinc borate, and dipentaerythritol are mixed according to the mass ratio of 2:2:2:1:0.5:0.5:1) and put into the grinding and dispersing machine for grinding for 2 hours; then add 20% acrylic acid Ester emulsion, 5 parts of chlorinated paraffin, dispersed at high speed (1200r / min) for 30 minutes to obtain the coating.

Embodiment 3

[0022] Weighing in parts by weight, 33 parts of water, 1 part of OP-10, 1 part of dioctyl phthalate, 35 parts of flame retardant (diethylphosphinate aluminum, melamine, polyphosphoric acid Ammonium, rutile titanium dioxide, activated clay, basic zinc carbonate, and dipentaerythritol are mixed according to the mass ratio of 2:2:2:1:0.5:0.5:1) and put into the grinding and dispersing machine for grinding for 2 hours; then add 24 Parts of acrylate emulsion, 6 parts of low molecular weight polyethylene wax (2000-3000), disperse at high speed (1200r / min) for 30 minutes to obtain the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com