Long-acting fluorescent pavement material and preparation method thereof

A pavement material and fluorescence technology, applied in luminescent coatings, epoxy resin coatings, coatings, etc., can solve the problems of short luminous time and low luminous intensity, and achieve long luminous time, high luminous intensity and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

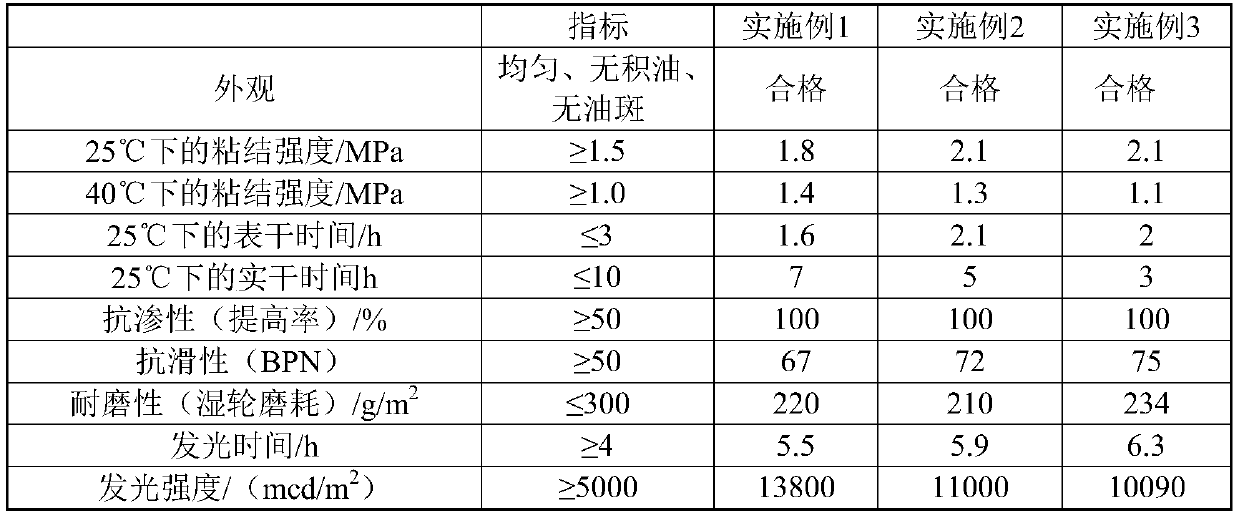

Examples

Embodiment 1

[0036] Fluorescent pavement material, its composition is: 40 parts E51 epoxy resin, 25 parts calcium sulfide powder, 1 part pure polyester matting resin, 2 parts vinyl triamine, 3 parts polydimethylsiloxane, polydodecane 2 parts of acyl dodecylamide, 12 parts of alkylphenol polyoxyethylene ether TX-1012 and 30 parts of kaolin; all in parts by mass.

[0037] The preparation method of the fluorescent pavement material, the specific steps are:

[0038] A: Heating the ring resin to 50℃, then shearing at a shear rate of 2500 r / min, then adding calcium sulfide powder to the epoxy resin, after shearing for 5 minutes, adding pure polyester matting resin, polydimethyl Siloxane, polydodecanoyl dodecylamide, alkylphenol polyoxyethylene ether TX-10 and kaolin, and then sheared at a shear rate of 5500 rpm for 45 minutes to obtain component A of the long-lasting fluorescent material;

[0039] B: Mix component A and vinyltriamine, stir for 2 minutes, and obtain the fluorescent pavement mate...

Embodiment 2

[0042] Fluorescent pavement material, its composition is: E40 epoxy resin 55 parts, zinc sulfide powder 35 parts, pure polyester matting resin 3.5 parts, vinyl triamine 7.5 parts, polydimethylsiloxane 5 parts, polydodecane 2.5 parts of dodecylamide, 18 parts of alkylphenol polyoxyethylene ether NP-10 and 50 parts of barium sulfate; all are in parts by mass.

[0043] The preparation method of the fluorescent pavement material, the specific steps are:

[0044] A: Heat the epoxy resin to 55°C, then shear it at a shear rate of 2800 rpm, then add phosphor powder to the epoxy resin, and after shearing for 8 minutes, add pure polyester matting resin, polydimethyl Siloxane, polydodecanoyl dodecylamide, alkylphenol polyoxyethylene ether NP-10 and barium sulfate, and then sheared at a shear rate of 6500 rpm for 35 minutes to obtain component A of the long-lasting fluorescent material;

[0045] B: Mix component A and vinyltriamine, stir for 2.5 minutes, and obtain the fluorescent paveme...

Embodiment 3

[0048] The fluorescent pavement material is composed of: 70 parts of bisphenol A epoxy resin, 40 parts of strontium sulfide powder, 6 parts of pure polyester matting resin, 15 parts of vinyl triamine, 7 parts of polydimethylsiloxane, 5 parts of dodecanoyl dodecylamide, 24 parts of fatty alcohol polyoxyethylene ether AEO-9 and 70 parts of talc; all in parts by mass.

[0049] The preparation method of the fluorescent pavement material, the specific steps are:

[0050] A: Heat the epoxy resin to 60°C, then shear it at a shear rate of 3000 r / min, then add strontium sulfide powder to the epoxy resin, and after shearing for 10 minutes, add pure polyester matting resin, polydimethylformaldehyde base siloxane, polydodecanoyl laurylamide, fatty alcohol polyoxyethylene ether AEO-9 and talc, and then sheared at a shear rate of 8000 rpm for 30 minutes to obtain component A of the long-lasting fluorescent material;

[0051] B: Mix component A and vinyltriamine, stir for 3 minutes, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glow time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com