Alcohol-resistant acid-resistant room-temperature vulcanized organic silicon sealant and preparation method thereof

A technology of room temperature vulcanization and silicone, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems that silicone rubber cannot meet the requirements, and achieve excellent electrical properties, chemical inertness, and good adhesion The effect of sex and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 200g of 107 silicone rubber with a viscosity of 50000mPa·s, 100g of dimethyl silicone oil with a viscosity of 100mPa·s into the container, vacuumize and stir for 5-10 minutes, then add 18g of methyl mixed ketoximosilane, 9g of vinyl tributyl ketone Oxime silane and vacuumize and stir for 20-30 minutes, then add 15g of surface-treated fumed silica A380 into the planetary mixer and stir slowly until it is completely soaked, then vacuumize and stir for 30-60 minutes, then add 400g Surface-treated filler, 3g surface-treated carbon black, 2g hexamethyldisilazane, vacuum and stir for 60-90 minutes, and finally add 9g vinyl tributylketoximosilane, 4gKH560, 3gKH792, 0.4g di Dibutyltin laurate, vacuumed and stirred for 15-20 minutes, stirred evenly, discharged and filled into aluminum toothpaste tubes to seal tightly, that is, alcohol-resistant, acid-type room temperature vulcanized silicone sealant.

[0030] The prepared alcohol-resistant, acid-type room temperature vulcani...

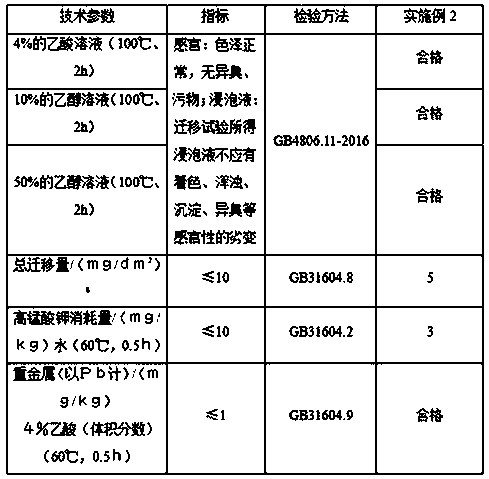

Embodiment 2

[0033] Add 100g of 107 silicone rubber with a viscosity of 20000mPa·s, 100g of 107 silicone rubber with a viscosity of 50000mPa·s, and 100g of dimethyl silicone oil with a viscosity of 500mPa·s into the container, vacuumize and stir for 5-10 minutes, then add 25g of methyl tributyl Ketoxime silane, 10g vinyl tributylketoxime silane and vacuum stirring for 20 to 30 minutes, then add 7.5g of surface-treated fumed silica A380 into the planetary mixer and stir slowly until it is completely infiltrated, then vacuum Increase the stirring speed and stir for 30-60 minutes, then add 600g of surface-treated filler, 3g of surface-treated carbon black, 2g of butyl triethylsilylacetate, vacuumize and stir for 60-90 minutes, and finally add 10g of vinyl tributyl Ketoxime silane, 4g KH550, 1.5g KH792, 0.4g dialkyltin dihydroxy acid, vacuum and stir for 15-20 minutes, after stirring evenly, discharge the material and fill it in an aluminum toothpaste tube and seal it tightly, that is, alcohol ...

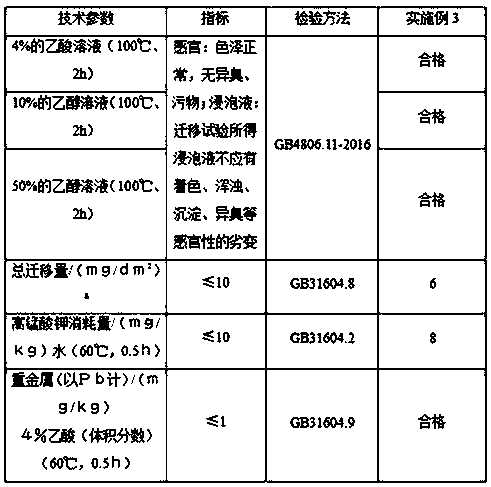

Embodiment 3

[0037]Add 200g of 107 silicone rubber with a viscosity of 20000mPa·s, 100g of dimethyl silicone oil with a viscosity of 1000mPa·s into the container, vacuumize and stir for 5-10 minutes, then add 25g of phenyltributylketoximosilane, 12.5g of vinyltrimethicone butanone oximinosilane and vacuumize and stir for 20-30 minutes, then add 25g of surface-treated fumed silica A380 into the planetary mixer and stir at a slow speed until it is completely infiltrated, then vacuumize and stir for 30-60 minutes at an accelerated stirring speed, then Add 700g of surface-treated filler, 3g of surface-treated carbon black, 2g of tris(6-isocyanatohexyl) isocyanate, vacuumize and stir for 60-90 minutes, and finally add 12.5g of vinyl tributylketoximosilane, 6g of KH550 , 1gKH792, 0.4g dialkyldiaryloxide tin, vacuum and stir for 15-20 minutes, after stirring evenly, discharge and fill in aluminum toothpaste tubes to seal tightly, that is, alcohol-resistant, acid-type room temperature vulcanized si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap